A well-tuned chainsaw is essential for clean cuts, consistent power, and long engine life. Yet many users overlook one of the most critical maintenance tasks: carburetor adjustment. Whether you're cutting firewood in your backyard or working on a logging job, an improperly adjusted carburetor can lead to poor fuel economy, stalling, excessive smoke, or even engine damage. Understanding how to fine-tune your chainsaw’s carburetor ensures peak performance and extends the life of your tool.

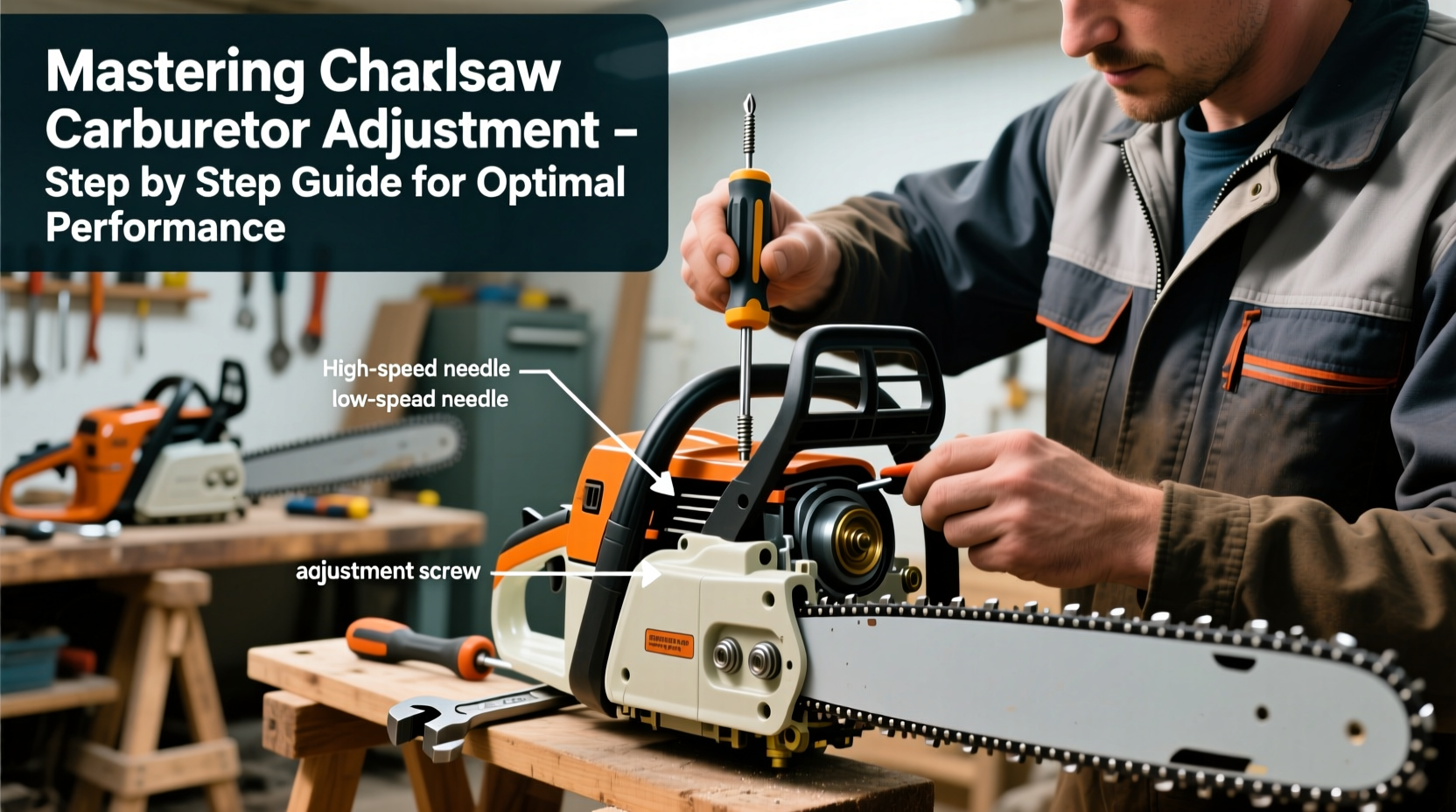

Modern chainsaws typically feature three adjustable screws labeled “L” (low-speed), “H” (high-speed), and sometimes “T” (idle). These control the air-fuel mixture at different throttle ranges. While factory settings work for general use, environmental changes, altitude, fuel quality, and wear over time can throw the balance off. Learning to adjust these settings gives you full control over your saw’s responsiveness and efficiency.

Understanding the Carburetor and Its Role

The carburetor mixes air and fuel in precise ratios before delivering the mixture to the engine’s combustion chamber. Too much fuel (rich mixture) causes sluggish performance and carbon buildup; too little (lean mixture) leads to overheating and potential piston damage. The goal of adjustment is to achieve a balanced mixture across idle, mid-range, and full-throttle operation.

The three primary adjustment screws serve distinct functions:

- L (Low-Speed Jet): Controls fuel flow at low RPMs and during acceleration from idle.

- H (High-Speed Jet): Regulates fuel delivery at full throttle, affecting maximum power and cooling.

- T (Idle Speed Screw): Adjusts how fast the engine runs when not engaged, ensuring the chain doesn’t move unnecessarily.

These screws are sensitive—often requiring only quarter-turn adjustments. Over-tightening or improper tuning can cause irreversible engine damage. Always refer to your chainsaw’s manual for specific specifications and safety warnings before beginning.

Step-by-Step Guide to Carburetor Adjustment

Follow this methodical process to safely and effectively adjust your chainsaw’s carburetor. Perform adjustments in a clean, well-ventilated area after warming up the engine for accurate readings.

- Warm Up the Engine: Run the chainsaw for 3–5 minutes to reach operating temperature. Cold engines behave differently than warm ones, so adjustments should reflect real-world conditions.

- Check Air Filter and Spark Plug: A clogged air filter or worn spark plug can mimic carburetor issues. Replace or clean both components before adjusting.

- Locate Adjustment Screws: Identify the L, H, and T screws on the side of the carburetor. They are usually marked with letters or color-coded caps.

- Set Idle Speed (T Screw): Start the saw and let it idle. Turn the T screw clockwise to increase idle speed, counterclockwise to reduce it. Adjust until the engine runs smoothly but the chain does not rotate.

- Adjust Low-Speed Mixture (L Screw): With the engine running, slowly turn the L screw clockwise until the engine begins to lose power, then back it out counterclockwise until it sputters. Find the midpoint where acceleration is crisp and smooth.

- Adjust High-Speed Mixture (H Screw): Rev the engine to full throttle. Turn the H screw clockwise (lean) until the exhaust note becomes high-pitched or \"sharp,\" then slightly back it out counterclockwise (richen) until the sound stabilizes with strong power and moderate smoke.

- Recheck Idle and Chain Movement: After adjusting L and H, verify that the chain remains stationary at idle. Readjust T if necessary.

- Test Under Load: Cut into wood to evaluate real-world performance. If the saw bogs down under load, slightly enrich the L setting. If it smokes excessively or overheats, lean out the H setting slightly.

This sequence ensures all phases of engine operation are optimized. Small incremental turns yield better results than aggressive adjustments.

Common Adjustment Mistakes and How to Avoid Them

Even experienced users make errors when tuning carburetors. Recognizing these pitfalls helps prevent engine damage and inconsistent performance.

| Mistake | Consequence | Prevention |

|---|---|---|

| Over-tightening adjustment screws | Damaged needle seats, permanent lean condition | Turn no more than 1/4 turn at a time; stop if resistance increases |

| Ignoring air filter condition | False rich/lean diagnosis due to restricted airflow | Clean or replace filter before any adjustment |

| Tuning a cold engine | Inaccurate mixture calibration | Always warm up the saw first |

| Leaving the chain engaged at idle | Safety hazard and poor idle stability | Ensure chain brake is engaged and T screw properly set |

“Many carburetor problems aren’t actually carb issues—they’re symptoms of dirty filters, old fuel, or ignition faults.” — Dale Richards, Small Engine Technician with 22 years of field experience

Real-World Example: Restoring a Stumbling Saw

Tom, a homeowner in northern Vermont, noticed his Husqvarna 455 Rancher was losing power when cutting hardwood. It started easily but bogged down under load and emitted black smoke. He assumed the carburetor needed cleaning, but after checking, he found the air filter was clean and the spark plug showed signs of a rich mixture—wet and sooty.

Instead of disassembling the carb, Tom decided to re-tune it using the proper adjustment sequence. After warming the engine, he backed out the L screw slightly to improve transition response and leaned the H screw just enough to sharpen the exhaust note. The result? Immediate improvement in cutting power and reduced smoke. The saw now starts easier and holds full throttle without hesitation. This case illustrates how simple tuning—without part replacement—can restore full function.

Frequently Asked Questions

How often should I adjust my chainsaw carburetor?

Under normal conditions, annual adjustment is sufficient. However, if you notice performance drops, changes in altitude, or switch fuel brands, re-evaluation may be needed. Frequent users should check settings every few months.

Can I damage the engine by adjusting the carburetor incorrectly?

Yes. Running too lean—especially at high speed—can cause overheating, piston scoring, or seizure. Conversely, a severely rich mixture leads to carbon buildup, fouled plugs, and wasted fuel. Always make small adjustments and test thoroughly.

Do all chainsaws have adjustable L, H, and T screws?

No. Some newer models, especially those with electronic fuel injection (EFI), auto-adjust or limit user access to protect warranty compliance. Check your owner’s manual to confirm adjustability.

Essential Tuning Checklist

Use this checklist before and during carburetor adjustment to ensure accuracy and safety:

- ✅ Chainsaw is warmed up and running

- ✅ Work area is clear of debris and flammable materials

- ✅ Air filter is clean and properly seated

- ✅ Spark plug is in good condition

- ✅ Fuel is fresh (< 30 days old) and correctly mixed (for 2-stroke)

- ✅ Chain brake is functional and engaged during idle adjustment

- ✅ Adjustment tools are non-metallic and fit snugly

- ✅ Original screw positions noted (optional but recommended)

Final Thoughts and Action Plan

Carburetor adjustment isn’t magic—it’s mechanics combined with observation. By understanding how each screw influences engine behavior and following a disciplined tuning process, you gain reliable control over your chainsaw’s performance. The benefits go beyond power: improved fuel efficiency, cleaner emissions, and extended engine life all follow from a properly tuned system.

Don’t wait for problems to arise. Schedule regular inspection and minor tuning as part of your seasonal maintenance routine. A few minutes of attention can save hours of frustration—and potentially costly repairs—down the line.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?