Brewing your own craft beer is more than a hobby—it’s a creative process that blends science, patience, and passion. With the right knowledge and tools, anyone can produce high-quality, flavorful beer from their kitchen. While commercial breweries use complex systems, homebrewing has become increasingly accessible thanks to simplified methods and widespread availability of ingredients. This guide walks you through every stage of brewing your first batch, from selecting equipment to bottling and tasting.

Understanding the Brewing Process

At its core, beer is made from four primary ingredients: water, malted barley, hops, and yeast. The brewing process transforms these elements into alcohol and flavor through a series of controlled steps—mashing, boiling, fermenting, and conditioning. Each phase plays a crucial role in determining the final taste, color, and aroma of your beer.

The journey begins with extracting fermentable sugars from malted grains. These sugars are then boiled with hops, which contribute bitterness, flavor, and aroma. After cooling, yeast is added to begin fermentation—the magical transformation of sugar into alcohol and carbon dioxide. Finally, the beer conditions, allowing flavors to mature before packaging.

Essential Equipment Checklist

Before brewing, gather the necessary tools. You don’t need expensive gear to start—basic homebrew kits are available for under $150 and include most essentials.

- Large stainless steel or enamel pot (5+ gallons)

- Fermenter (food-grade plastic bucket or glass carboy)

- Airlock and stopper

- Siphon and tubing

- Bottles (flip-top or standard beer bottles)

- Bottle capper and caps

- Auto-siphon or racking cane

- Thermometer (digital preferred)

- Hydrometer (to measure sugar levels)

- Sanitizer (e.g., Star San or iodophor)

- Long spoon (stainless steel or heat-resistant plastic)

“Sanitation is 90% of successful brewing. Even the best recipe can be ruined by contamination.” — James Spencer, Founder of Basic Brewing Radio

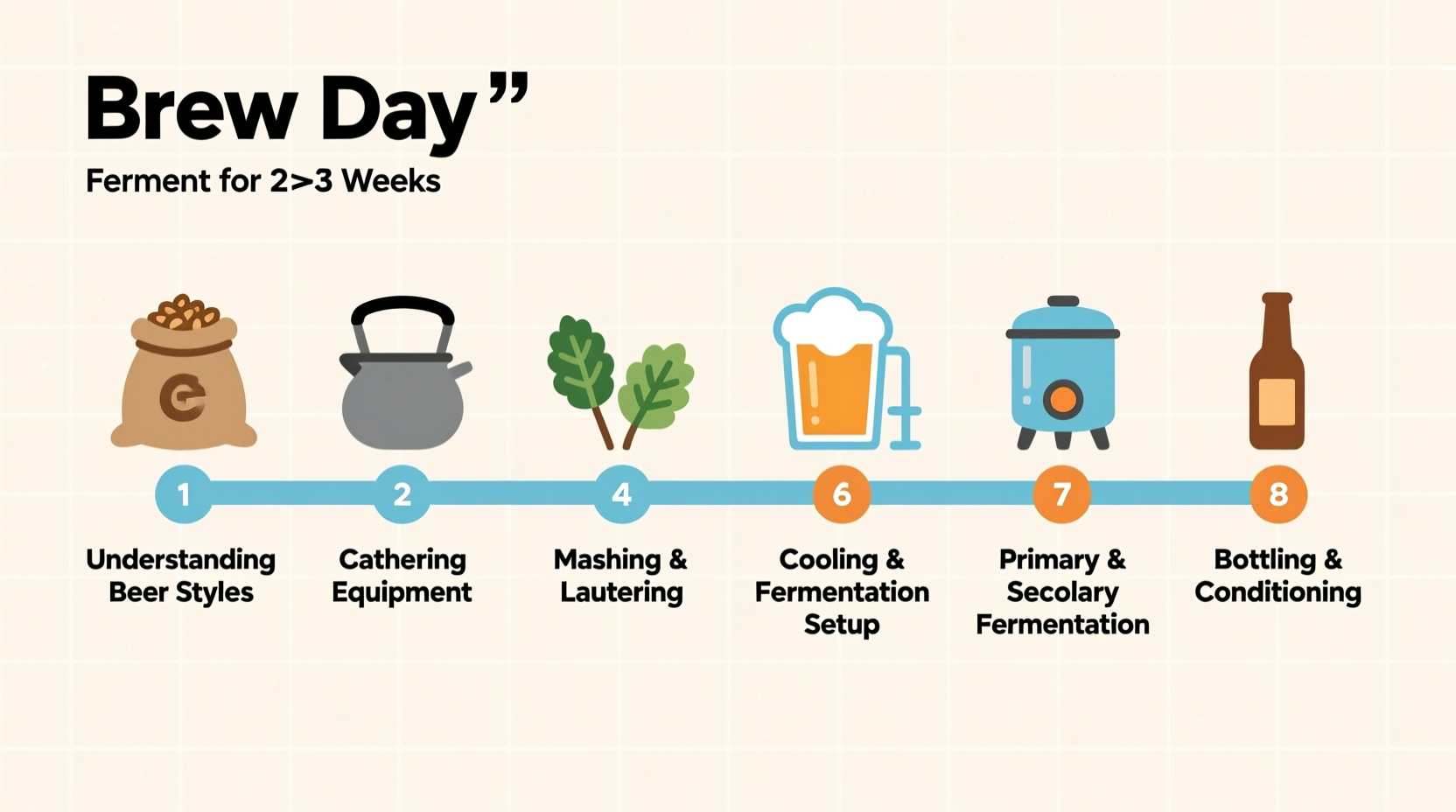

Step-by-Step Brewing Timeline

Follow this sequence to brew your first all-grain or extract batch. This example uses a beginner-friendly pale ale recipe but applies broadly across styles.

- Day 1: Brew Day (3–4 hours)

- Sanitize all equipment that will touch cooled wort.

- Heat 2.5 gallons of water to 150–160°F (65–71°C).

- Add crushed malt (5–6 lbs) and hold at 152°F (67°C) for 60 minutes (mash).

- Lauter (separate liquid from grain) by sparging with hot water (~170°F).

- Boil the collected wort for 60 minutes, adding hops at designated times:

- 60 minutes left: Bittering hops (e.g., 1 oz Cascade)

- 15 minutes left: Flavor hops

- 5 minutes left: Aroma hops

- Cool wort rapidly to 65–70°F using an ice bath or wort chiller.

- Transfer to fermenter and top up to 5 gallons with clean water.

- Take a hydrometer reading (original gravity ~1.048–1.052).

- Rehydrate dry yeast or pitch liquid yeast.

- Seal fermenter with airlock and store in a dark place at 68°F (20°C).

- Days 2–7: Active Fermentation

- Bubbles in the airlock indicate fermentation is underway.

- Avoid opening the fermenter—contamination risk is highest now.

- Temperature stability is critical; avoid fluctuations above 75°F (24°C).

- Day 14: Check Final Gravity

- Sanitize a test tube and hydrometer.

- Draw a sample and measure specific gravity.

- If two consecutive readings (24 hours apart) are stable and near 1.010, fermentation is complete.

- Day 15: Bottling Day

- Dissolve 3/4 cup corn sugar in 2 cups boiling water (priming solution).

- Mix priming solution into beer gently (avoid splashing).

- Siphon into bottles, cap securely.

- Store bottles at room temperature (70°F) for 2 weeks to carbonate.

- Day 29+: Taste Test

- Chill one bottle and open carefully.

- Evaluate clarity, carbonation, aroma, and balance.

- Note observations for future batches.

Common Pitfalls and How to Avoid Them

Even experienced brewers make mistakes. Recognizing common issues early improves consistency and quality.

| Issue | Possible Cause | Solution |

|---|---|---|

| Flat beer | Insufficient priming sugar, poor mixing, old yeast | Measure sugar precisely, mix thoroughly, ensure fermentation completed |

| Off-flavors (sour, medicinal) | Contamination, improper sanitation | Sanitize everything that touches post-boil wort |

| Cloudy beer | Yeast disturbance during transfer, no cold crash | Rack carefully, chill before bottling |

| Overly bitter beer | Too many late-hop additions, long boil times | Follow recipe hop schedules closely |

| No fermentation activity | Cold temps, dead yeast, incorrect pitching | Check temperature, rehydrate dry yeast properly, use fresh yeast |

Real Example: From First Batch to Award-Winning Homebrew

When Mark Thompson brewed his first pale ale in 2018, the result was cloudy, over-carbonated, and slightly sour. Discouraged but curious, he joined a local homebrew club and learned proper sanitation techniques. He invested in a hydrometer and began tracking data meticulously. By his fourth batch—a well-balanced American IPA—he won second place in a regional competition. Today, he consults for small breweries on fermentation practices. His advice? “Don’t chase perfection early. Focus on consistency, learn from each batch, and enjoy the process.”

Choosing Ingredients for Flavor and Balance

Your ingredient choices define your beer’s character. Beginners often start with malt extract to simplify the mash process, but all-grain brewing offers greater control.

Malt: Base malts like Pale Ale Malt provide fermentable sugars. Specialty grains (crystal, chocolate, roasted) add color and complexity. Steep them in hot water (but not boil) for extract brewing.

Hops: Choose varieties based on alpha acid percentage (bitterness) and aromatic profile. Cascade and Centennial offer citrus notes; Willamette and Fuggle bring earthiness.

Yeast: Ale yeasts (Saccharomyces cerevisiae) work at 65–75°F and produce fruity esters. Lager yeasts require colder fermentation (45–55°F) and longer conditioning. Dry yeast (e.g., Safale US-05) is reliable and affordable for starters.

FAQ

How long does homebrew take from start to finish?

Total time is typically 4–6 weeks: 3–4 weeks for fermentation and conditioning, plus 2 weeks for bottle carbonation. Some styles like lagers or stouts benefit from longer aging.

Can I brew beer without boiling?

No. Boiling sterilizes the wort, extracts hop bitterness, and stops enzymatic activity. Skipping it risks infection and unbalanced flavor.

Is homebrewing legal?

In the U.S., federal law allows adults to brew up to 100 gallons per year per person (200 gallons per household). Most states permit homebrewing, but check local regulations.

Final Thoughts and Next Steps

Mastering craft beer brewing starts with a single batch. Each step—from sanitizing your spoon to popping open your first homemade pint—builds knowledge and confidence. Don’t be discouraged by imperfections; even flawed batches teach valuable lessons. As your skills grow, experiment with new styles, yeast strains, and fermentation techniques. Consider joining a homebrew club or entering competitions to gain feedback.

Brewing connects you to centuries of tradition while encouraging innovation. Whether you're crafting a crisp pilsner or a bold stout, the process rewards attention to detail and curiosity. Now that you understand the fundamentals, it’s time to brew.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?