When it comes to energy efficiency in homes and buildings, few factors matter more than insulation performance. At the heart of that performance is the R-value—a measure of thermal resistance that determines how well a material resists heat flow. Understanding how to figure R value isn’t just for engineers or contractors; it’s essential knowledge for homeowners, builders, and anyone aiming to reduce energy costs and improve comfort. This guide breaks down what R-value means, how to calculate it, and how to apply it effectively in real-world scenarios.

What Is R-Value and Why It Matters

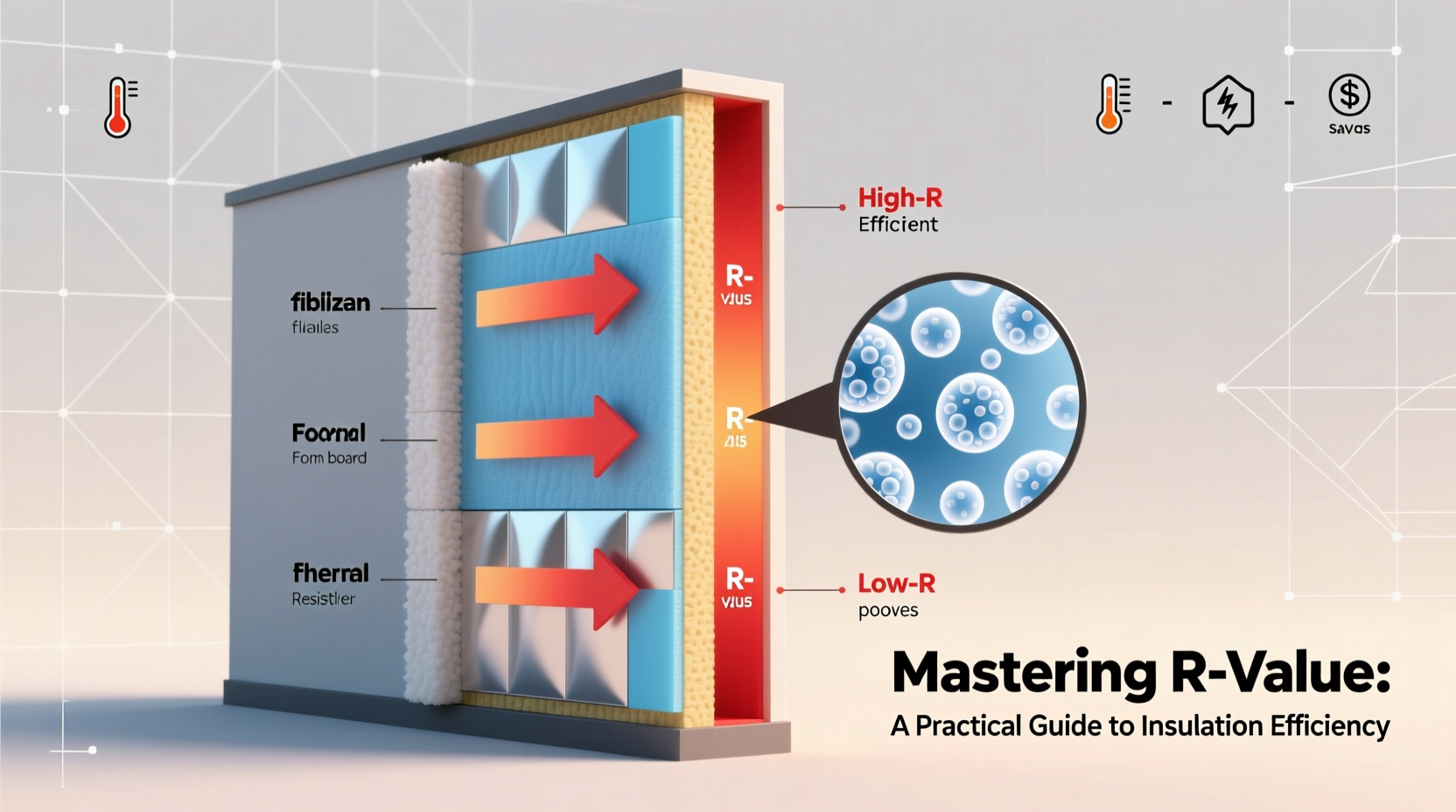

R-value measures a material’s ability to resist conductive heat flow. The higher the R-value, the better the insulation performs. It is expressed in units of °F·ft²·hr/Btu (in the U.S.), indicating how many degrees of temperature difference one square foot of material can withstand per hour with one British Thermal Unit of heat transfer.

Heat naturally moves from warmer to cooler areas—through walls, ceilings, and floors. In winter, indoor heat escapes outside; in summer, outdoor heat penetrates indoors. Insulation with sufficient R-value slows this transfer, reducing the workload on heating and cooling systems and lowering energy bills.

The U.S. Department of Energy recommends different R-values based on climate zones. For example, attics in colder northern regions may require R-49 to R-60, while southern zones might only need R-30 to R-38. Choosing the right R-value for your region ensures optimal efficiency without over-insulating.

“R-value is the backbone of effective thermal design. Getting it wrong means paying more in energy every month.” — Dr. Linda Chen, Building Science Researcher, Oak Ridge National Laboratory

How to Figure R Value: A Step-by-Step Guide

Calculating R-value depends on whether you're assessing existing materials or planning new installations. Here's how to do it correctly:

- Determine the insulation type. Common materials include fiberglass (batts or blown), cellulose, spray foam, rigid foam boards, and mineral wool. Each has a different inherent resistance per inch.

- Check the manufacturer’s specifications. Most insulation products list their R-value per inch. For example, fiberglass batts typically offer R-3.1 to R-4.3 per inch, while spray polyurethane foam can reach R-6.5 per inch.

- Measure the thickness of the installed insulation. Use a ruler or tape measure to determine depth in inches, especially in attics or wall cavities.

- Multiply thickness by R-value per inch. If you have 10 inches of blown cellulose rated at R-3.8 per inch, the total R-value is 10 × 3.8 = R-38.

- Account for compression or gaps. Compressed insulation loses effectiveness. Batts stuffed into too-small spaces can lose up to 50% of their rated R-value.

- Sum layers if multiple materials are used. When combining insulation types (e.g., foam board plus fiberglass), add their individual R-values together.

Comparing Insulation Materials by R-Value

Not all insulations are created equal. Here’s a comparison of common types based on typical R-value per inch and key characteristics:

| Material | R-Value per Inch | Average Cost (per R-1) | Best Applications |

|---|---|---|---|

| Fiberglass Batts | R-3.1 to R-4.3 | $0.30–$0.50 | Walls, attics (standard framing) |

| Blown Cellulose | R-3.2 to R-3.8 | $0.40–$0.60 | Attics, hard-to-reach cavities |

| Spray Polyurethane Foam (Closed-cell) | R-6.0 to R-7.0 | $1.50–$2.50 | Roofs, walls, air sealing |

| Mineral Wool | R-3.0 to R-4.0 | $0.50–$0.80 | Fire-prone areas, sound control |

| Expanded Polystyrene (EPS) | R-3.6 to R-4.0 | $0.70–$1.00 | Foundations, exterior sheathing |

While high R-value per inch is desirable, cost, space constraints, and installation method also influence material choice. Spray foam offers excellent performance but at a premium price. Fiberglass is affordable and widely available but requires careful installation to avoid gaps.

Real-World Example: Upgrading Attic Insulation

Consider a homeowner in Minnesota with an older home containing only R-19 fiberglass batts in the attic. Winters are harsh, and heating bills are consistently high. After an energy audit, they learn that the recommended R-value for their zone is R-49.

The solution? Adding loose-fill cellulose over the existing batts. Since cellulose provides about R-3.7 per inch, they need approximately 8 additional inches (R-30) to reach the target. They blow in 8 inches of cellulose, bringing the total to R-49. Within one heating season, their gas bill drops by 28%, and indoor temperatures remain more consistent.

This case illustrates how accurately figuring R-value leads to measurable savings and comfort improvements. Skipping the calculation could result in under-insulating—or overspending on unnecessary material.

Common Mistakes That Undermine R-Value Performance

Even with high-rated insulation, poor practices can drastically reduce real-world efficiency. Avoid these pitfalls:

- Thermal bridging: Heat flows through studs, joists, and headers where insulation is absent. Continuous insulation (like rigid foam on exterior walls) helps mitigate this.

- Improper air sealing: Gaps around windows, outlets, and ducts allow air movement, bypassing insulation entirely. Sealants and tapes are critical complements to insulation.

- Compressing batts: Squeezing insulation into narrow spaces reduces its thickness and R-value. Use the correct size for the cavity.

- Ignoring vapor barriers: In cold climates, vapor diffusion can cause condensation within walls. Proper placement of vapor retarders prevents moisture buildup.

- Overlooking ventilation: In attics, balanced intake and exhaust prevent heat buildup and moisture, preserving insulation longevity.

FAQ: Frequently Asked Questions About R-Value

Can you have too much insulation?

Yes. Beyond a certain point, adding more insulation yields diminishing returns. Over-insulating can trap moisture, lead to mold, and increase costs without meaningful energy savings. Follow regional recommendations and consult energy auditors for guidance.

Does R-value change over time?

Some materials settle or degrade. Loose-fill fiberglass can settle by up to 20%, reducing its effective R-value. Cellulose settles less due to denser packing. Closed-cell spray foam remains stable for decades. Check attic insulation every 5–10 years for compaction.

Is higher R-value always better?

Not necessarily. In mild climates, very high R-values may not justify the cost. Balance performance, budget, and space. For example, in a tight wall cavity, choosing a material with higher R-value per inch (like spray foam) makes more sense than thick batts.

Action Plan: Checklist for Optimizing Insulation Efficiency

Follow this checklist to ensure your insulation delivers maximum performance:

- Identify your climate zone using the DOE map or local building codes.

- Determine recommended R-values for each area (attic, walls, basement).

- Inspect current insulation: type, thickness, condition.

- Calculate existing R-value using thickness and manufacturer data.

- Select appropriate insulation material based on R/inch, cost, and space.

- Seal air leaks before installing new insulation.

- Install insulation to full depth without compression or gaps.

- Verify final R-value matches target requirements.

- Schedule periodic inspections to check for settling or damage.

Conclusion: Take Control of Your Home’s Energy Efficiency

Mastering how to figure R value empowers you to make informed decisions about insulation—one of the most impactful upgrades for comfort and energy savings. Whether you’re retrofitting an older home or designing a new build, understanding thermal resistance ensures you invest wisely and achieve lasting results. Don’t guess when you can calculate. Assess your current setup, compare materials, and apply best practices to unlock true insulation efficiency.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?