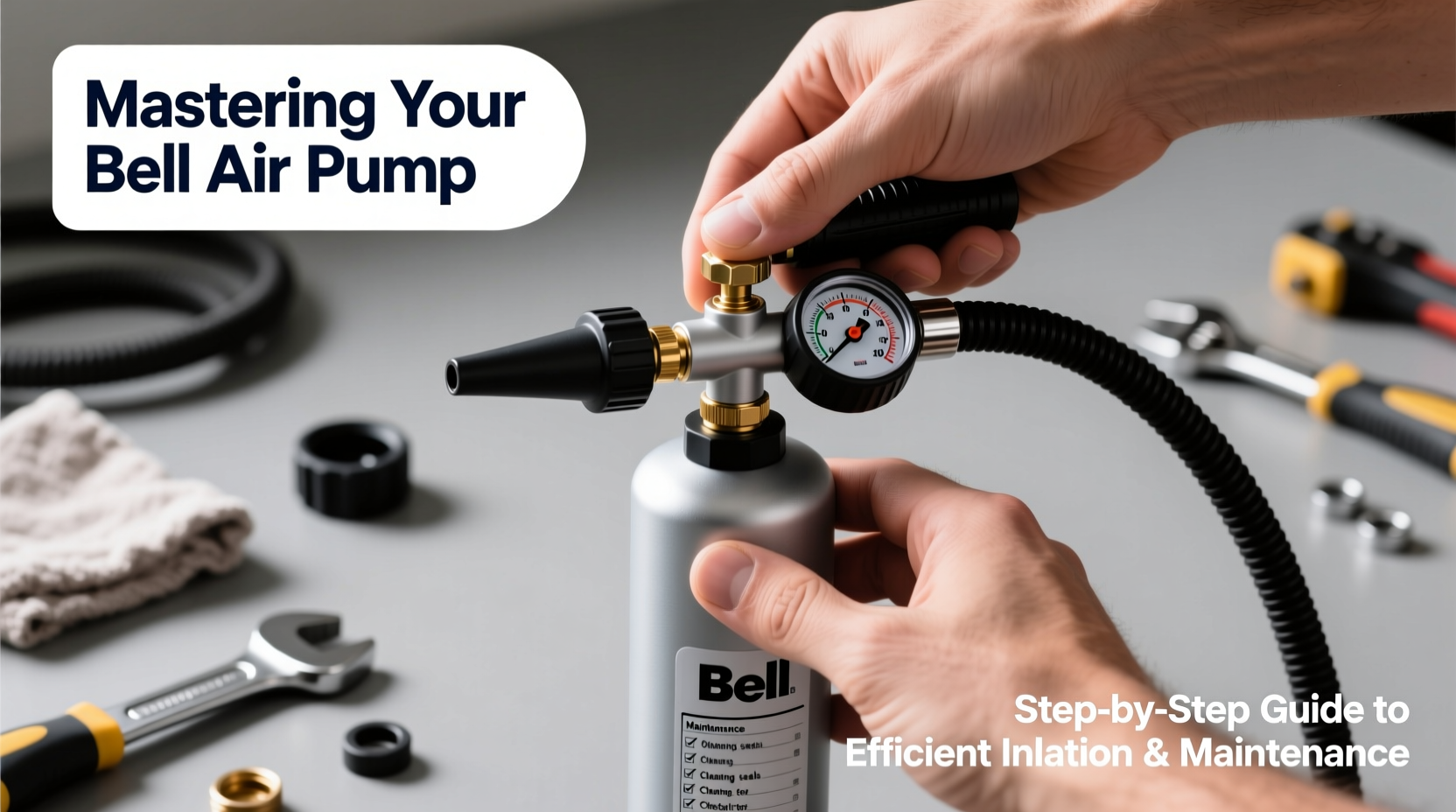

Bell air pumps are a staple in homes, garages, and outdoor adventures for inflating everything from bicycle tires to air mattresses and sports equipment. Despite their simplicity, many users overlook the nuances of proper operation and upkeep, leading to reduced efficiency, frequent breakdowns, or inconsistent performance. Mastering your Bell air pump isn’t just about plugging it in and pressing a button—it’s about understanding its mechanics, using it correctly, and maintaining it to extend its lifespan. This comprehensive guide walks you through every phase of effective use and care, ensuring your pump delivers reliable results every time.

Understanding Your Bell Air Pump: Key Components and Functions

Bell air pumps come in various models—manual (hand or foot-operated) and electric—but they all share core components that contribute to their functionality. Knowing these parts helps you troubleshoot issues and operate the device more efficiently.

- Pressure Gauge: Displays the current PSI (pounds per square inch), allowing precise inflation control.

- Nozzle Attachments: Typically include needle valves for balls, standard Schrader valves for bikes and car tires, and Presta adapters for high-pressure road bike tires.

- Hose and Connector: Transfers air from the pump to the item. A kinked or damaged hose reduces airflow.

- Motor (Electric Models): Powers the piston or diaphragm mechanism. Overheating can occur if used beyond recommended intervals.

- Check Valve: Prevents backflow of air into the pump after inflation, maintaining pressure stability.

Familiarity with these elements allows you to diagnose problems early—like a failing gauge showing inaccurate readings or a worn seal causing slow inflation.

Step-by-Step Guide to Efficient Inflation

Proper inflation ensures optimal performance of your equipment and prevents over- or under-inflation, which can lead to damage or safety risks. Follow this sequence for consistent, accurate results.

- Identify the Required PSI: Check manufacturer guidelines on the tire, ball, or inflatable product. For example, most road bikes require 80–130 PSI, while mountain bikes need 30–50 PSI.

- Select the Correct Nozzle: Attach the appropriate adapter to the hose. Use the needle valve for basketballs and soccer balls, Schrader for car tires and most bikes.

- Prepare the Valve: Unscrew the dust cap and press the valve core briefly to release any trapped air or moisture.

- Connect Securely: Press the nozzle firmly onto the valve. You should hear a brief hiss as it seals. On electric pumps, ensure the latch clicks into place.

- Inflate Gradually: Begin pumping. If using a manual pump, maintain steady strokes. For electric models, monitor the gauge and stop when near target pressure.

- Check and Adjust: Disconnect and recheck pressure. Add small bursts of air if needed. Avoid exceeding maximum PSI.

- Seal and Store: Replace valve caps to prevent leaks and contamination.

This method minimizes wear on both the pump and the inflated item, especially important for sensitive gear like performance bicycles or air beds.

Essential Maintenance Practices for Longevity

Regular maintenance is often overlooked but is crucial for keeping your Bell air pump functioning optimally. A well-maintained pump operates more efficiently, lasts longer, and avoids sudden failures during critical use.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Clean nozzle and hose | After every 5 uses | Prevents clogs and contamination |

| Lubricate piston (manual models) | Every 3 months | Reduces friction and wear |

| Inspect power cord (electric models) | Monthly | Prevents electrical hazards |

| Test pressure gauge accuracy | Biannually | Ensures correct readings |

| Store in dry environment | Always | Prevents rust and mold |

“Most pump failures stem from neglect, not design flaws. A few minutes of monthly care can extend a pump’s life by years.” — Carlos Mendez, Automotive Tool Specialist

Common Pitfalls and How to Avoid Them

Even experienced users make mistakes that compromise performance. Recognizing these errors helps you avoid unnecessary frustration.

- Overusing Electric Pumps Continuously: Running an electric Bell pump for more than 10–15 minutes without a break can overheat the motor. Allow 5–10 minutes of cooldown between sessions.

- Forcing Nozzles Onto Valves: Misalignment or excessive pressure can damage valve cores. Align carefully and apply even pressure.

- Ignoring Pressure Limits: Overinflation can burst inner tubes or degrade material integrity in inflatables.

- Storing with Attached Hoses: Coiled hoses can develop permanent kinks. Detach and store flat or loosely coiled.

Real-World Example: Preparing for a Weekend Camping Trip

Consider Sarah, an avid camper who relies on her Bell electric air pump to inflate her two-person air mattress and kayak each weekend. Last summer, she arrived at her campsite only to find the pump wouldn’t start. After troubleshooting, she realized sand had entered the motor housing during beach storage, and the cord insulation was cracked from being left in direct sunlight.

She now follows a strict routine: after each trip, she wipes down the pump, stores it in a ventilated toolbox, and checks connections before packing. She also keeps a printed checklist in her gear bag. Since implementing these changes, her pump has performed flawlessly for over a year—saving her time, stress, and replacement costs.

Quick Maintenance Checklist

Use this concise checklist to keep your Bell air pump in top condition:

- ✅ Clean nozzles and hose after each use

- ✅ Inspect for cracks or fraying in hoses and cords

- ✅ Verify gauge accuracy against a known standard

- ✅ Lubricate moving parts (manual models)

- ✅ Store in a dry, temperature-controlled area

- ✅ Test operation monthly, even if not in regular use

Frequently Asked Questions

Why does my electric Bell pump shut off during use?

This is typically due to thermal overload protection. The motor overheats from prolonged use. Turn it off, allow it to cool for 10–15 minutes, and resume with shorter intervals. Ensure ventilation around the unit is unobstructed.

Can I use my Bell pump for car tires?

Yes, most Bell electric pumps are designed for 12V car batteries and include a car tire nozzle. However, they are best suited for temporary inflation or emergencies—not for fully inflating large truck or SUV tires from zero. Check your model’s maximum PSI output (usually 120–150 PSI).

How do I know if the pressure gauge is accurate?

Compare readings with a calibrated digital gauge or another trusted pump. If discrepancies exceed 3–5 PSI, consider replacing the gauge or the unit. Some local auto shops will test gauges upon request.

Conclusion: Take Control of Your Inflation Needs

Mastering your Bell air pump means more than just inflating objects—it’s about confidence in reliability, precision in execution, and foresight in maintenance. Whether you're prepping a bike for a morning ride, setting up camp, or topping off a soccer ball for game day, a well-maintained pump makes the process faster, safer, and more effective. By applying the steps and insights outlined here, you’re not just extending the life of a tool—you’re investing in peace of mind and performance.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?