When shopping for clothing, bedding, or upholstery, you’ve likely come across labels listing “rayon” or “viscose.” At first glance, these fabrics seem interchangeable—both drape beautifully, feel soft against the skin, and carry a silk-like sheen. But are they truly the same material, or is there a subtle distinction that matters to consumers and manufacturers alike? The answer lies not in marketing but in chemistry, production methods, and industry terminology.

Retailers often use \"rayon\" and \"viscose\" interchangeably, leading to widespread confusion. However, understanding the relationship between the two can help you make informed choices about comfort, sustainability, durability, and care. This article clarifies the nuances, traces their shared history, compares performance characteristics, and offers practical guidance for buyers and sewists alike.

Understanding Rayon: A Category, Not Just a Fabric

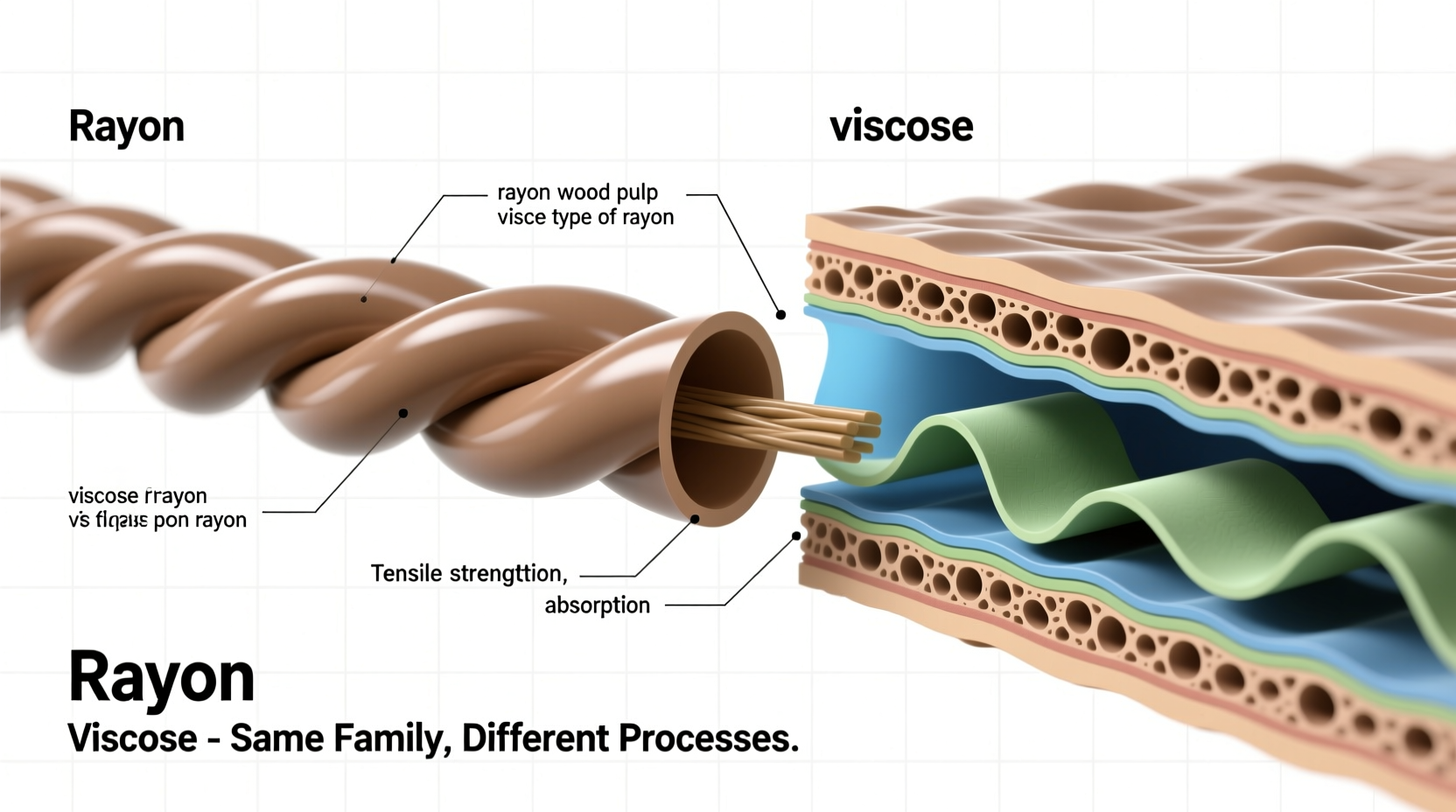

The term “rayon” refers broadly to a class of semi-synthetic fibers made from regenerated cellulose—typically derived from wood pulp. Unlike natural fibers such as cotton or wool, rayon is processed chemically to transform raw plant material into a usable textile fiber. It was first developed in the late 19th century as an affordable alternative to silk, earning the nickname “artificial silk.”

There are several types of rayon, each defined by its manufacturing process:

- Viscose rayon – The most common form, produced using the viscose process.

- Modal – Made from beech tree pulp, known for enhanced strength and softness.

- LyoCell (TENCEL™) – Created using a closed-loop solvent system, considered more eco-friendly.

So while all viscose is technically a type of rayon, not all rayon is viscose. Think of rayon as the umbrella category—like “dairy”—and viscose as one specific product under it—like “yogurt.” This distinction is critical when comparing fabric qualities or evaluating environmental impact.

The Viscose Process: How It’s Made

Viscose is named after the viscous organic liquid used during its production. The process, developed in the 1890s by British chemist Charles Frederick Cross and his colleagues, involves several stages:

- Pulping: Wood chips (usually from bamboo, eucalyptus, or pine) are broken down into pure cellulose.

- Alkali treatment: Cellulose is soaked in sodium hydroxide (caustic soda), forming alkali cellulose.

- Aging: The alkali cellulose is exposed to air to increase reactivity.

- Xanthation: Treated with carbon disulfide to create cellulose xanthate—a yellow, crumbly substance.

- Dissolving: The xanthate is dissolved in sodium hydroxide to form a viscous orange-brown solution called “viscose.”

- Spinning: The viscose solution is forced through a spinneret into an acid bath, where it solidifies into filaments.

- Washing & Finishing: Filaments are washed, bleached, and cut into staple fibers or left as continuous filament yarns.

This chemical-intensive method gives viscose its signature drape and luster but raises environmental concerns due to the use of toxic solvents like carbon disulfide. While modern facilities have improved safety and waste recovery, many smaller producers still lack adequate controls.

“Viscose remains one of the most widely used textiles globally, but its legacy of pollution demands better regulation and innovation.” — Dr. Lena Patel, Sustainable Textile Researcher, Institute of Materials Science

Comparing Properties: Rayon vs Viscose

Since viscose is a subset of rayon, direct comparison may seem redundant—but consumers benefit from understanding how labeling affects expectations. Below is a detailed breakdown of key attributes:

| Property | Rayon (General) | Viscose (Specific Type) |

|---|---|---|

| Softness | Very soft, smooth texture | Exceptionally soft, silk-like hand feel |

| Drape | Excellent flow and fluidity | Superior drape; ideal for flowing garments |

| Moisture Absorption | High (more than cotton) | Very high; breathable but slow-drying |

| Strength (Dry) | Moderate | Low to moderate |

| Wet Strength | Significantly reduced when wet | Loses up to 50% strength when damp |

| Shrinkage | Prone to shrinking without proper care | High risk of shrinkage if machine washed |

| Luster | Can be matte or glossy depending on finish | Naturally shiny; often mimics silk |

| Eco-Impact | Varies by production method | Higher pollution potential due to chemical use |

As shown, viscose tends to represent the standard bearer for traditional rayon properties—particularly softness and sheen. However, its weakness when wet and environmental footprint set it apart from newer rayon variants like Lyocell.

Real-World Example: A Designer’s Dilemma

Consider Sofia Reyes, a sustainable fashion designer based in Portland who launched a summer dress line marketed as “eco-luxury.” She initially selected a fabric labeled simply as “rayon” from a supplier in India. After production, customers reported that dresses lost shape after gentle washing, despite care instructions advising hand wash only.

Upon further inquiry, Sofia discovered the fabric was actually viscose rayon made from bamboo—but processed using outdated methods involving heavy chemical discharge. Worse, the supply chain lacked transparency. She switched to TENCEL™ Lyocell, another type of rayon but produced sustainably with minimal water waste and non-toxic solvents. Customer satisfaction improved dramatically, and return rates dropped by 70% within six months.

This case illustrates why distinguishing between types of rayon isn’t just academic—it impacts product quality, brand reputation, and environmental responsibility.

Care and Maintenance Tips

Whether labeled rayon or viscose, these fabrics require careful handling to maintain appearance and longevity. Their high absorbency makes them comfortable in warm weather, but also vulnerable to damage from heat, moisture, and friction.

Step-by-Step Guide to Washing Viscose/Rayon

- Check the label: Confirm whether the item is machine-washable. Many viscose garments recommend dry cleaning.

- Turn inside out: Protects the surface from pilling and abrasion.

- Use cold water: Hot water increases shrinkage and weakens fibers.

- Select gentle cycle: Or hand wash using mild detergent formulated for delicates.

- Minimize agitation: Avoid wringing or twisting; gently press out excess water.

- Flat dry: Lay on a clean towel away from direct sunlight to prevent warping and fading.

- Iron with caution: Use low heat and a pressing cloth. Steam can cause shine marks.

For long-term storage, fold rather than hang viscose blouses or dresses—hanging can stretch the shoulders over time due to the fabric’s low resilience.

Sustainability and Ethical Considerations

One of the biggest misconceptions about viscose is that it’s inherently “natural” because it comes from wood. While the source material is renewable, the transformation process often negates ecological benefits. Carbon disulfide, a key chemical in viscose production, is hazardous to workers and ecosystems if not properly managed. According to the Changing Markets Foundation, some viscose factories release up to 200 kg of pollutants per ton of fiber produced.

In contrast, newer rayon technologies like Lyocell (sold under the brand name TENCEL™) use a non-toxic amine oxide solvent in a closed-loop system, recycling over 99% of water and chemicals. This makes Lyocell a far more sustainable option—even though it still falls under the broader rayon category.

Consumers seeking ethical alternatives should look beyond generic “rayon” labels and prioritize certified fibers such as:

- TENCEL™ – Certified biodegradable and sustainably sourced.

- LENZING™ ECOVERO™ – A viscose variant made with 50% lower emissions and water usage.

- FSC-certified wood pulp – Ensures responsible forestry practices.

Frequently Asked Questions

Is viscose just another name for rayon?

Essentially, yes—but with nuance. Viscose is the most common type of rayon, made via the viscose process. So while all viscose is rayon, not all rayon is viscose. Other forms include modal and lyocell, which differ in production and performance.

Can I machine wash viscose clothing?

Some viscose items are labeled as machine washable, especially when blended with stronger fibers like polyester. However, pure viscose is best hand washed in cold water and laid flat to dry. Machine washing risks shrinking, stretching, or weakening the fibers.

Why does my rayon shirt lose shape after washing?

Rayon and viscose have low elasticity and poor wet strength. When wet, the fibers swell and become fragile. Agitation during washing or hanging to dry can cause permanent deformation. To preserve shape, always follow care instructions precisely and avoid excessive moisture exposure.

Final Checklist Before Buying Rayon or Viscose Fabrics

- ✅ Read the label carefully—look for specific terms like “viscose,” “modal,” or “TENCEL.”

- ✅ Assess intended use—avoid viscose for activewear or items requiring frequent washing.

- ✅ Prioritize certified sustainable versions (e.g., ECOVERO, TENCEL) when possible.

- ✅ Test drape and texture in person if buying online—viscose feels cooler and smoother than other rayons.

- ✅ Confirm care instructions match your lifestyle—dry-clean-only garments may not be practical for everyday wear.

Conclusion: Knowledge Is Your Best Fabric Tool

The debate over rayon vs viscose isn't about choosing one over the other—it's about recognizing that “rayon” is a family of fabrics, and “viscose” is its most widely used, yet problematic, member. Understanding this distinction empowers you to make smarter decisions, whether you're selecting a summer blouse, designing a capsule collection, or advocating for greener fashion practices.

Don’t let vague labeling dictate your choices. Demand transparency, read care tags closely, and consider the full lifecycle of the clothes you wear. By doing so, you support innovation in sustainable textiles and extend the life of your wardrobe—one thoughtful purchase at a time.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?