Polyester is one of the most widely used synthetic fibers in the world, found in clothing, sportswear, outdoor gear, and home textiles. But as awareness of environmental impact grows, consumers and brands alike are questioning the true cost of this durable fabric. The central debate centers on two forms: recycled polyester and virgin polyester. While both serve functional purposes, their ecological footprints differ significantly. Understanding these differences is essential for making informed, sustainable choices.

The textile industry accounts for nearly 10% of global carbon emissions and is a major contributor to microplastic pollution and water consumption. Polyester alone makes up over half of all fiber production worldwide. As demand for fast fashion and performance apparel continues, the choice between recycled and virgin polyester becomes not just a matter of preference, but of planetary responsibility.

What Is Virgin Polyester?

Virgin polyester is a synthetic fiber derived entirely from fossil fuels—primarily petroleum. It is manufactured through a chemical process that transforms crude oil into polyethylene terephthalate (PET), which is then spun into fibers for textiles. This process begins with extracting non-renewable resources, followed by refining, polymerization, extrusion, and weaving or knitting into fabric.

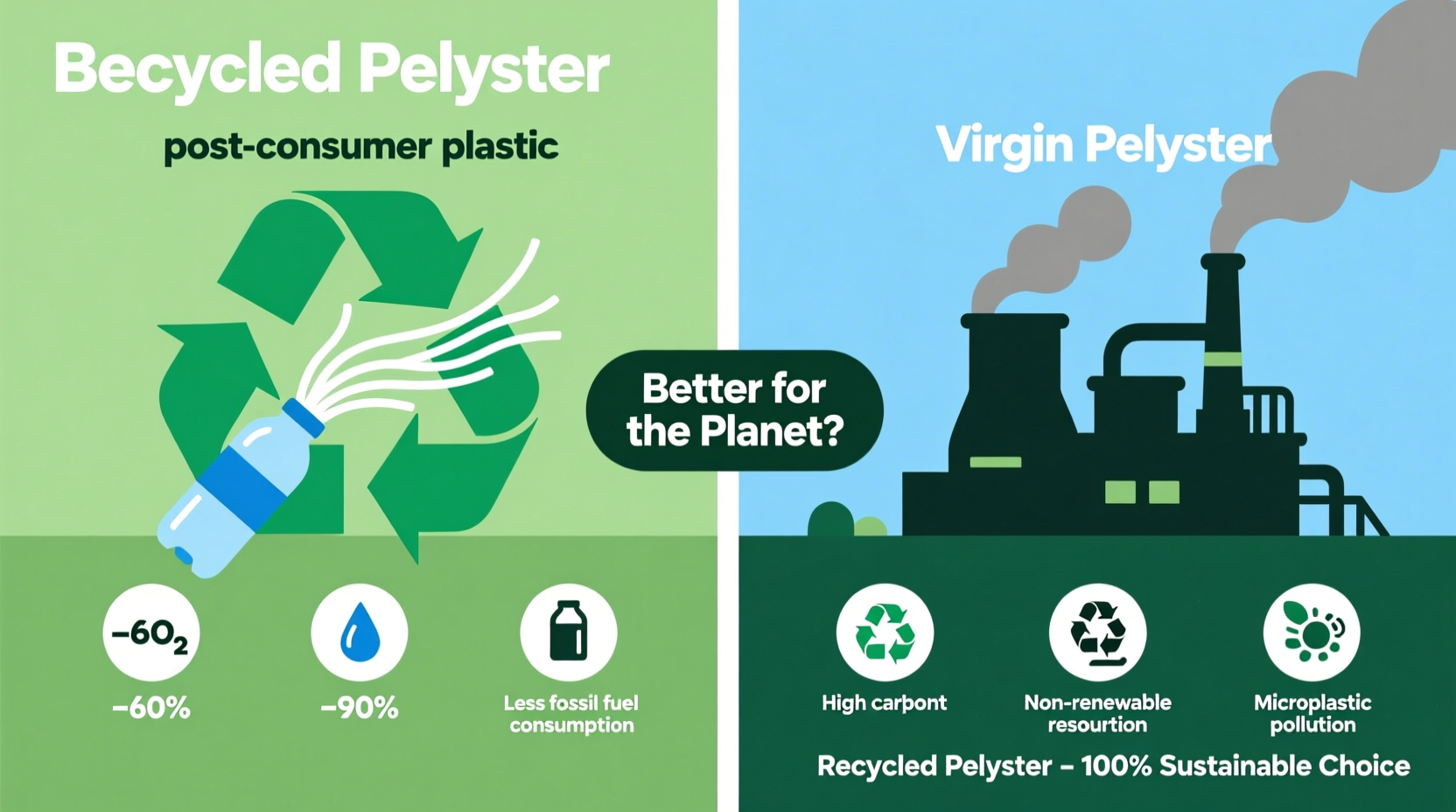

The production of virgin polyester is energy-intensive. It requires high heat and pressure to convert raw materials into usable fibers. According to the Textile Exchange, producing one ton of virgin polyester emits approximately 7.3 kilograms of CO₂ equivalent. Additionally, the extraction and processing of petroleum contribute to habitat destruction, air and water pollution, and greenhouse gas emissions throughout the supply chain.

Despite its environmental drawbacks, virgin polyester remains popular due to its low cost, durability, moisture-wicking properties, and resistance to shrinking and stretching. However, because it is not biodegradable, discarded polyester garments can persist in landfills for hundreds of years, slowly breaking down into microplastics that infiltrate ecosystems.

What Is Recycled Polyester?

Recycled polyester, often labeled as rPET (recycled polyethylene terephthalate), is made by reprocessing existing plastic materials—most commonly used plastic bottles and post-industrial textile waste—into new fibers. The recycling process typically involves collecting, sorting, cleaning, shredding, melting, and reforming the plastic into polyester chips, which are then spun into yarn.

Using recycled materials reduces reliance on virgin fossil fuels and diverts plastic waste from landfills and oceans. For example, one metric ton of rPET saves approximately 5.7 cubic meters of landfill space and reduces energy consumption by 30–50% compared to virgin polyester production. It also cuts CO₂ emissions by an estimated 30–75%, depending on the recycling method and transportation logistics.

Major brands like Patagonia, Adidas, and The North Face have adopted rPET in their product lines, citing sustainability goals and consumer demand for eco-conscious materials. However, recycled polyester is not without limitations. Its quality can degrade slightly with each recycling cycle, and contamination in feedstock (such as mixed plastics or dyes) can affect consistency and colorfastness.

Environmental Impact Comparison

When evaluating which material is better for the planet, several key factors must be considered: resource use, energy consumption, emissions, waste generation, and end-of-life impact.

| Factor | Virgin Polyester | Recycled Polyester |

|---|---|---|

| Raw Material Source | Petroleum (non-renewable) | Post-consumer plastic waste (e.g., bottles) |

| Energy Use | High (125 MJ/kg) | Moderate (60–80 MJ/kg) |

| CO₂ Emissions | ~7.3 kg CO₂e per kg | ~3.0–5.0 kg CO₂e per kg |

| Water Consumption | Low (but upstream oil extraction uses water) | Low (mainly in cleaning phase) |

| Waste Diversion | Generates waste | Reduces plastic waste in environment |

| Microfiber Shedding | High (similar to rPET) | High (same fiber structure) |

| Biodegradability | No | No |

While recycled polyester clearly outperforms virgin polyester in terms of resource conservation and emissions, it is not a perfect solution. Both types shed microplastics during washing, contributing to ocean pollution. Additionally, mechanical recycling—the most common method—has limits in scalability and fiber quality. Chemical recycling offers promise by breaking down polyester to its molecular components for higher-quality reuse, but it remains expensive and underdeveloped at scale.

“Switching to recycled polyester is a meaningful step toward circularity, but we must also address fiber shedding and improve take-back systems.” — Dr. Jane Thompson, Sustainable Materials Researcher, University of Leeds

Real-World Example: How One Brand Made the Switch

In 2018, outdoor apparel company Patagonia transitioned over 80% of its polyester-lined products to recycled materials. By sourcing rPET from post-consumer bottles and factory scraps, the brand reduced its dependence on virgin plastic and cut annual CO₂ emissions by thousands of metric tons. Their \"Worn Wear\" program further extends garment life through repair, resale, and recycling.

This shift wasn’t without challenges. Sourcing consistent, high-quality rPET required investment in supplier partnerships and quality control. Dyeing processes had to be adjusted due to variations in base color from recycled feedstock. Yet, customer response was overwhelmingly positive, reinforcing that sustainability can align with performance and brand loyalty.

Patagonia’s experience illustrates that while transitioning to recycled materials demands effort, the long-term environmental and reputational benefits are substantial. It also highlights the importance of transparency—sharing sourcing details and lifecycle impacts helps consumers make informed decisions.

Limitations and Misconceptions

Despite growing enthusiasm for recycled polyester, several misconceptions persist. One common belief is that rPET is fully sustainable. In reality, it delays but does not eliminate plastic pollution. Because rPET is still plastic, it will eventually break down into microfibers unless captured at end-of-life.

Another misconception is that all recycled polyester comes from plastic bottles. While bottle-to-fiber recycling is widespread, some rPET is sourced from pre-consumer industrial waste, such as fabric scraps from manufacturing. Post-consumer content is generally preferred for greater environmental benefit, but labeling standards vary, making it difficult for consumers to verify claims.

Moreover, recycling infrastructure remains fragmented globally. In many regions, collection rates for plastic bottles are low, limiting the availability of feedstock. Even when collected, contamination and lack of sorting technology prevent full recovery. Without systemic improvements in waste management, the growth of rPET may plateau.

Actionable Steps for Consumers and Brands

Choosing between recycled and virgin polyester isn’t just about individual purchases—it’s part of a broader movement toward sustainable consumption. Below is a checklist for making more responsible decisions:

- For Consumers:

- Choose clothing made with certified recycled polyester (look for GRS or RCS labels).

- Wash synthetic clothes less frequently and use a microfiber filter or laundry bag.

- Support brands with take-back programs or repair services.

- Avoid fast fashion; invest in durable, timeless pieces.

- Dispose of old garments responsibly—donate or recycle when possible.

- For Brands:

- Transition to minimum 50% rPET in polyester products by 2025.

- Invest in chemical recycling technologies for higher-quality reuse.

- Implement garment collection systems to close the loop.

- Disclose supply chain data, including rPET sourcing and recycling methods.

- Educate customers on care and disposal to reduce microfiber release.

Frequently Asked Questions

Is recycled polyester truly eco-friendly?

Recycled polyester is more environmentally friendly than virgin polyester in terms of energy use, emissions, and waste reduction. However, it is not a zero-impact material. It still sheds microplastics and relies on plastic inputs. True sustainability requires combining rPET with improved filtration, reuse systems, and reduced overall consumption.

Can recycled polyester be recycled again?

Yes, but with limitations. Mechanical recycling degrades fiber quality over time, so rPET can typically only be recycled once or twice before becoming too weak for textile use. Chemical recycling can restore polyester to virgin-like quality, but it is not yet widely available. Most rPET ends up in lower-grade applications like insulation or carpeting after its second life.

Does recycled polyester perform as well as virgin polyester?

In most cases, yes. Modern rPET matches virgin polyester in strength, moisture management, and durability. Some early versions had issues with color consistency or pilling, but advancements in processing have largely resolved these concerns. Performance differences are now minimal and often undetectable to the average user.

Toward a More Sustainable Future

The choice between recycled and virgin polyester is not binary. While recycled polyester represents a significant improvement over virgin, it should be seen as a transitional solution rather than a final answer. The ultimate goal must be to reduce overall plastic dependency, design for longevity, and build circular systems where materials are reused indefinitely.

Policymakers, manufacturers, and consumers all have roles to play. Governments can incentivize recycling infrastructure and regulate microfiber pollution. Brands can innovate with alternative materials like bio-based polyesters or plant-derived fibers. Individuals can shift toward mindful consumption—buying less, choosing well, and caring for what they own.

“We won’t recycle our way out of the plastic crisis. We need to redesign the system.” — Ellen MacArthur Foundation Report, 2023

Conclusion: Making the Right Choice

Between recycled and virgin polyester, the former is clearly the better option for the planet today. It conserves resources, reduces emissions, and keeps plastic waste out of ecosystems. But calling it “sustainable” oversimplifies a complex issue. Recycled polyester is a step forward—not the finish line.

The real power lies in collective action. Every purchase is a vote for the kind of world we want. By supporting transparent brands, demanding better recycling systems, and reducing our reliance on synthetic fibers, we can drive change beyond material substitution.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?