Selecting the right nozzle for your system—whether it's for cleaning, irrigation, 3D printing, or industrial spraying—can dramatically affect performance, efficiency, and longevity. A poorly matched nozzle leads to wasted resources, inconsistent results, and increased maintenance. Conversely, a well-chosen nozzle enhances precision, reduces operational costs, and adapts seamlessly across varying tasks. This guide explores the most reliable and versatile nozzle types available today, offering practical insights for optimizing your setup regardless of application.

Understanding Nozzle Functionality and Key Metrics

Nozzles are more than simple outlets; they control flow rate, spray pattern, droplet size, pressure distribution, and directional accuracy. The effectiveness of any fluid-based system hinges on how well the nozzle converts input energy into usable output. Three primary factors determine nozzle suitability:

- Flow Rate (GPM or L/min): Determines how much fluid passes through per unit of time.

- Spray Pattern: Includes flat fan, full cone, hollow cone, solid stream, and misting variants.

- Droplet Size: Critical in applications like pesticide spraying or humidification where coverage and evaporation matter.

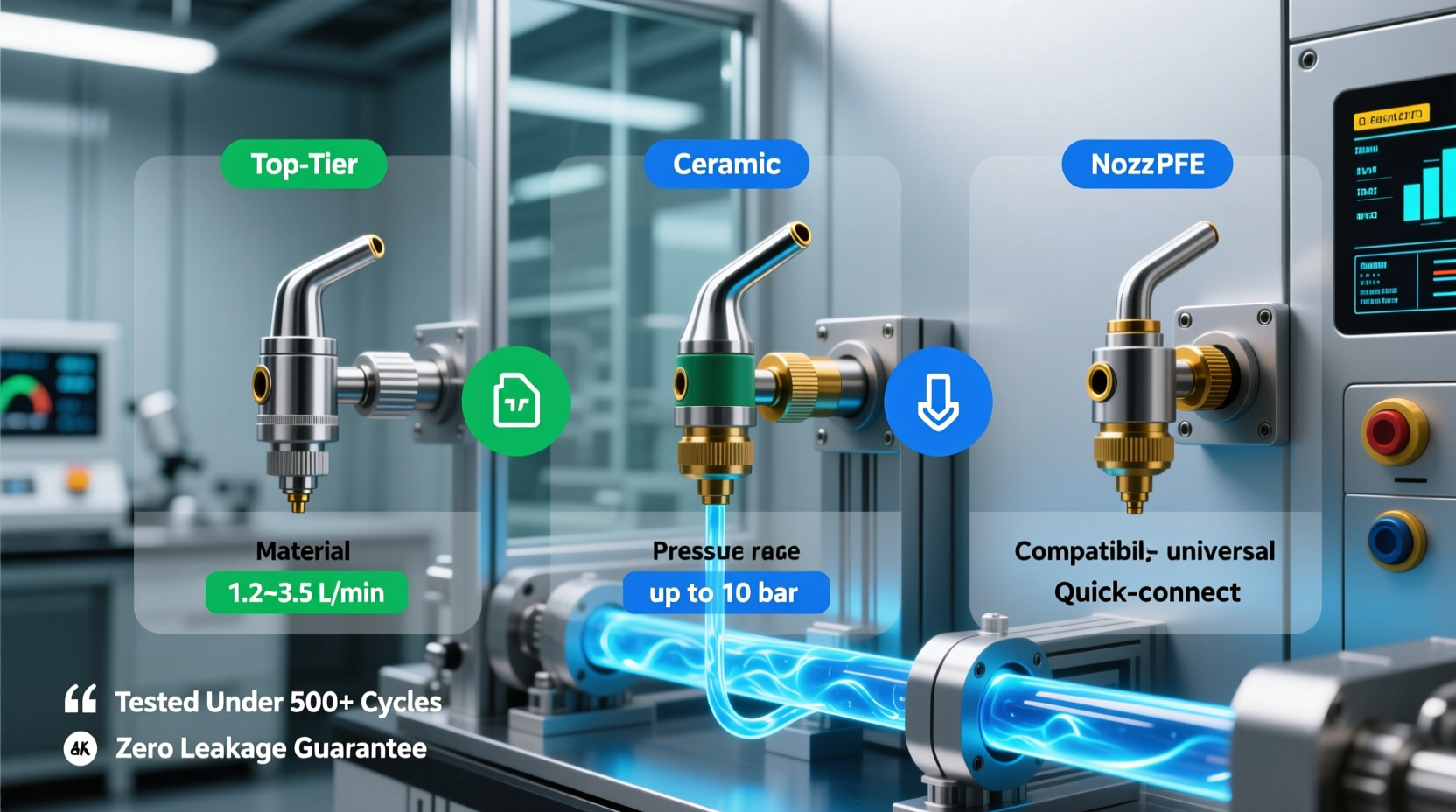

Additionally, material compatibility—such as resistance to abrasion, corrosion, or clogging—is vital for long-term reliability. For example, stainless steel nozzles endure high-pressure chemical environments, while PTFE-coated tips resist buildup in viscous media.

Top Nozzle Types by Application and Versatility

Different setups demand different nozzle behaviors. Below is a breakdown of leading nozzle types based on adaptability, durability, and performance across multiple fields.

| Nozzle Type | Best For | Versatility Score (1–5) | Lifespan (Avg. Hours) |

|---|---|---|---|

| Flat Fan Nozzle | Agricultural spraying, surface cleaning | 4.5 | 800–1,200 |

| Hollow Cone Nozzle | Cooling systems, gas scrubbing | 4.0 | 700–1,000 |

| Full Cone Nozzle | Irrigation, tank washing | 4.7 | 900–1,500 |

| Adjustable Spray Nozzle | General-purpose cleaning, gardening | 5.0 | 500–800 |

| Micro Orifice Nozzle | 3D printing, lab dispensing | 3.8 | 600–900 |

The adjustable spray nozzle stands out for home and light industrial use due to its ability to shift between mist, jet, and shower modes. In contrast, full cone nozzles offer uniform distribution ideal for large-area wetting without overspray.

Material Matters: Choosing Durable Construction

Even the most advanced design fails if built from subpar materials. Consider these common construction options:

- Brass: Cost-effective and machinable, but prone to corrosion in acidic or alkaline environments.

- Stainless Steel (304/316): Excellent corrosion and heat resistance; ideal for food processing and marine applications.

- Polymer (PP, PVDF): Lightweight and chemically inert; perfect for aggressive solvents.

- Ceramic: Extremely wear-resistant; used in sandblasting and abrasive slurry handling.

“Material selection often outweighs design complexity when predicting nozzle lifespan.” — Dr. Alan Zhou, Fluid Dynamics Engineer at Industrial Flow Solutions

In high-abrasion settings such as concrete cutting, ceramic nozzles last up to five times longer than steel equivalents despite higher initial cost. For general-purpose setups, however, reinforced polymers strike the best balance between price and resilience.

Mini Case Study: Optimizing Nozzles in a Commercial Car Wash

A mid-sized car wash facility in Phoenix struggled with inconsistent cleaning results and frequent downtime. Their original setup used low-cost plastic flat fan nozzles rated for 1,500 psi. Within six months, over 40% of nozzles showed signs of erosion, causing uneven water distribution and streaking.

The team replaced them with stainless steel full-cone nozzles designed for 2,000 psi operation. They also introduced a quarterly inspection protocol and installed inline filters to prevent particulate damage. After the upgrade:

- Cleaning cycle time dropped by 18%

- Maintenance intervals extended from 3 weeks to 11 weeks

- Customer satisfaction scores rose by 32%

This real-world case underscores that reliability isn’t just about brand names—it’s about matching nozzle specs to actual operating conditions.

Step-by-Step Guide to Selecting Your Ideal Nozzle

Follow this sequence to ensure optimal nozzle integration into your current system:

- Define the Primary Task: Is it rinsing, coating, cooling, or precision deposition?

- Measure System Pressure and Flow: Use gauges to record operating PSI and GPM at the delivery point.

- Select Spray Pattern: Choose based on target geometry—flat fans for linear surfaces, cones for volumetric coverage.

- Evaluate Fluid Properties: Account for viscosity, temperature, and chemical aggressiveness.

- Choose Material Accordingly: Match construction to environmental stressors.

- Test with Sample Units: Install trial nozzles and monitor performance over 48 hours.

- Document and Scale: Record findings and replicate successful configurations across all units.

Frequently Asked Questions

How do I know when a nozzle needs replacement?

Signs include reduced pressure, irregular spray patterns, visible wear at the orifice, or increased drift/overspray. A simple test: hold a piece of absorbent paper 12 inches from the nozzle. Uneven staining indicates degradation.

Can one nozzle work across multiple applications?

Yes—adjustable nozzles with interchangeable tips offer cross-functionality. However, dedicated nozzles typically deliver superior consistency and efficiency for specialized tasks.

Are expensive nozzles worth the investment?

In high-use or critical environments, yes. Premium nozzles may cost 2–3x more but often last 4–6x longer and improve process control, reducing waste and labor costs over time.

Essential Checklist Before Purchasing a Nozzle

Use this checklist to avoid mismatched components and ensure seamless integration:

- ✅ Confirm operating pressure range matches system output

- ✅ Verify thread type and connection size (NPT, BSP, etc.)

- ✅ Check compatibility with fluid chemistry (pH, solvents, particulates)

- ✅ Assess required coverage area and select appropriate spray angle

- ✅ Determine acceptable droplet size (fine mist vs. heavy impact stream)

- ✅ Evaluate ease of cleaning and availability of spare parts

- ✅ Review manufacturer warranty and technical support access

Conclusion: Make Informed Choices for Long-Term Success

The best nozzle in your setup isn’t always the most advanced or expensive—it’s the one that aligns precisely with your operational demands, material constraints, and maintenance capabilities. By focusing on reliability, versatility, and proper integration, you can achieve consistent performance, extend equipment life, and reduce both downtime and resource waste. Whether you're managing an industrial line, maintaining landscape irrigation, or fine-tuning a fabrication tool, investing time in nozzle selection pays dividends in quality and efficiency.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?