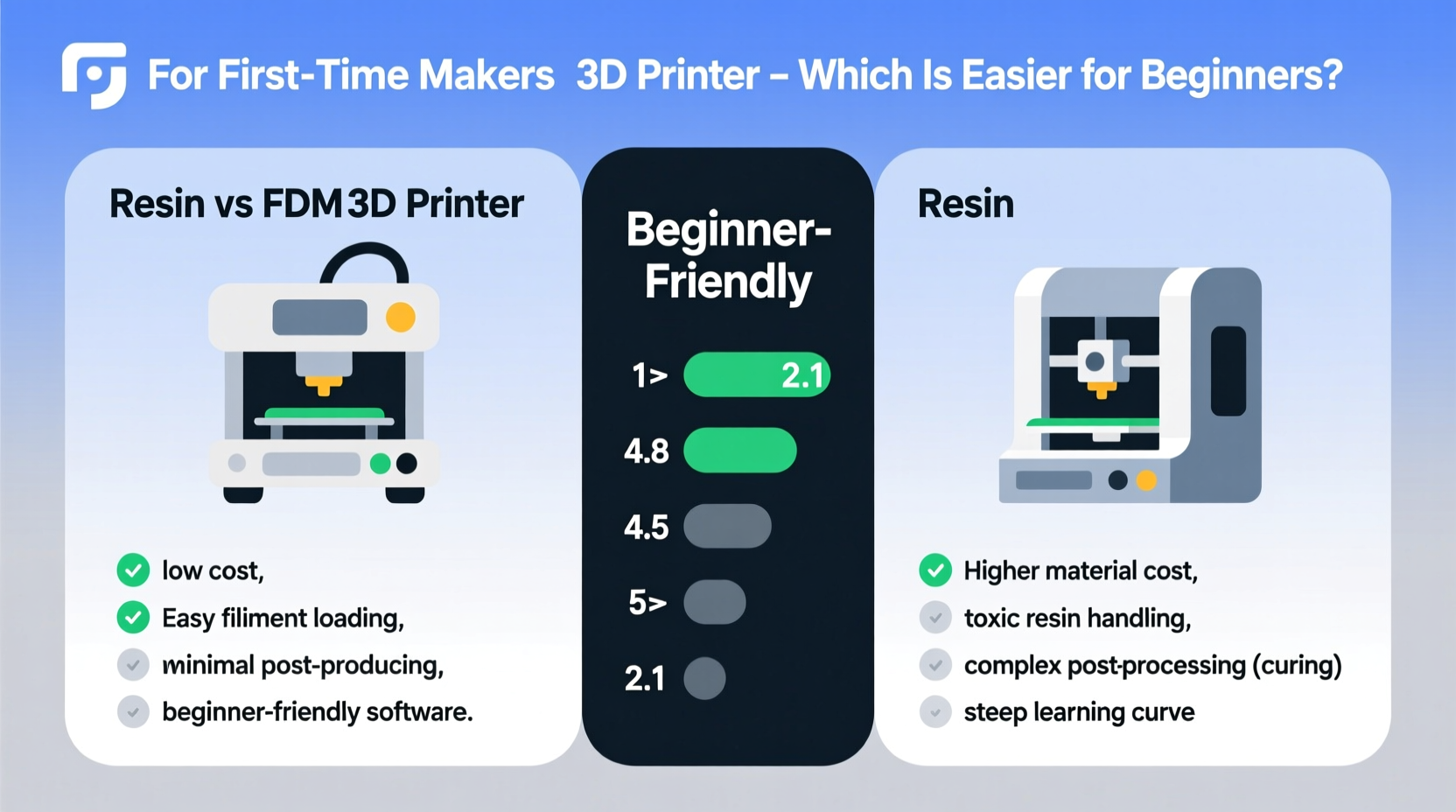

Choosing your first 3D printer can feel overwhelming. Two dominant technologies—Fused Deposition Modeling (FDM) and Resin (SLA/DLP/LCD)—offer very different experiences. While both can produce impressive results, the path to success varies dramatically. For a beginner, the question isn’t just about print quality or speed; it’s about accessibility, safety, maintenance, and how quickly you can go from unboxing to printing usable parts without frustration.

FDM printers extrude melted plastic layer by layer, much like a glue gun guided by software. Resin printers use light to cure liquid photopolymer into solid layers, resulting in smoother finishes and finer details. But that precision comes at a cost—literally and practically. So which technology truly wins when it comes to ease of entry?

Understanding the Core Differences

Before evaluating ease of use, it’s essential to understand what sets these two technologies apart at a fundamental level.

FDM (Fused Deposition Modeling) works by feeding a thermoplastic filament (like PLA or ABS) through a heated nozzle. The printer moves this nozzle precisely across the build plate, depositing molten material that cools and hardens into shape. It's mechanical, tactile, and relatively straightforward in concept.

Resin printing (stereolithography or SLA variants) uses a vat of liquid resin that solidifies when exposed to specific wavelengths of light—usually UV. A laser or LCD screen cures each layer from the bottom up (or top down), building the object upside down, layer by thin layer. The result is high resolution with minimal visible layer lines.

The difference in process leads to stark contrasts in user experience, especially for someone new to 3D printing.

Learning Curve and Initial Setup

For most beginners, the first few hours with a 3D printer are critical. If the setup is confusing or error-prone, motivation can drop fast.

FDM printers, particularly modern pre-assembled models like the Creality Ender 3 V3 SE, Prusa MINI+, or Bambu Lab A1, come nearly ready to use. After basic leveling (often auto-bed-leveling now), loading filament, and connecting via USB or SD card, users can start printing within minutes. The interface is usually simple, and troubleshooting common issues—like under-extrusion or warping—is well-documented across countless forums and YouTube tutorials.

In contrast, resin printers require more upfront attention. You must:

- Pour resin into the vat without spilling

- Ensure the build plate is perfectly leveled (Z-offset calibration is notoriously finicky)

- Clean the FEP film (the transparent bottom of the resin tank)

- Handle uncured resin carefully to avoid messes or exposure

A misaligned build plate by even 0.05 mm can cause prints to fail completely. Unlike FDM, where a slightly uneven first layer might still stick, resin demands near-perfect alignment from the start. This steep initial hurdle often discourages newcomers before they see their first successful print.

Safety and Workspace Considerations

This is where resin printing introduces significant complexity for beginners.

Uncured resin is toxic. It’s a skin irritant, harmful if inhaled as fumes, and requires careful handling. You need gloves, nitrile preferred, and good ventilation—ideally an enclosed space with an air purifier or exhaust system. Cleaning failed prints involves soaking them in isopropyl alcohol (IPA), which is flammable and also irritating to skin and lungs.

Disposal is another concern. You can’t pour leftover or contaminated resin down the drain. It must be cured fully under UV light before being treated as solid waste, following local regulations.

FDM printing, on the other hand, poses far fewer health risks. PLA filament, the most popular choice for beginners, emits minimal odor and low levels of volatile organic compounds (VOCs). While ABS should be printed in a ventilated area due to stronger fumes, PLA is safe enough for home offices or classrooms.

Workspace cleanliness is simpler too. FDM produces plastic strings (ooze) and dust from support removal, but cleanup is typically just wiping down surfaces and sweeping up scraps. No solvents required.

“Beginners often underestimate the chemical burden of resin printing. Safety isn’t optional—it’s part of daily operation.” — Dr. Lena Torres, Materials Scientist & Additive Manufacturing Consultant

Maintenance and Long-Term Usability

Reliability over time plays a major role in perceived ease of use. A printer that constantly needs tuning may frustrate even enthusiastic beginners.

FDM printers have moving parts—belts, pulleys, nozzles—that wear over time, but maintenance is generally mechanical and intuitive. Clearing a clogged nozzle, tightening belts, or replacing a worn PTFE tube are all tasks with abundant video guides and community support. Most issues are visible and diagnosable.

Resin printers introduce less mechanical wear but more consumable degradation. The FEP film at the bottom of the resin vat wears out after several hundred hours and must be replaced to maintain print quality. Resin itself has a shelf life and degrades if exposed to sunlight or moisture. Over time, oxygen inhibition and residue buildup reduce consistency.

Additionally, the resin tank needs regular cleaning. Leftover cured bits can create shadows during exposure, leading to failed prints. IPA baths require frequent replenishment, adding ongoing cost and effort.

While some newer resin printers offer features like replaceable vats and self-cleaning modes, these conveniences come at a premium price—often double or triple that of a capable FDM machine.

Print Quality vs. Practicality: What Matters Most to Beginners?

It’s true: resin prints look better out of the gate. Layer lines are nearly invisible, details are crisp, and surface finish rivals injection molding. For miniatures, dental models, or jewelry casting, resin is unmatched.

But beginners rarely need museum-grade detail. More often, they want to print functional parts—phone stands, drawer organizers, replacement knobs, or simple prototypes. For these applications, FDM’s slightly rougher finish is perfectly acceptable, especially when post-processing (sanding, priming) is factored in.

Moreover, FDM offers greater material flexibility. Beyond PLA, users can explore PETG (water-resistant), TPU (flexible), ASA (UV-resistant), and even carbon-fiber-infused filaments. Resin options exist (tough, flexible, castable), but they’re pricier, less standardized, and not always compatible across brands.

And let’s talk failure tolerance. With FDM, a failed print usually means wasted filament and time. With resin, a failed print means spilled liquid, wasted expensive material (resin costs ~$30–$50 per liter vs. $15–$25 for filament), and a messy cleanup. One large failed print can consume more in resin and IPA than an entire month of FDM printing.

| Factor | FDM | Resin |

|---|---|---|

| Initial Setup Time | 15–30 minutes | 45–90+ minutes |

| Safety Requirements | Minimal (ventilation for ABS) | Gloves, mask, ventilation, spill kit |

| Material Cost (per liter/kg) | $15–$25 | $30–$60 |

| Post-Processing | Sand supports, remove strings | Wash in IPA, UV cure, peel supports |

| Failure Cleanup | Remove part, reheat bed | Scrape vat, filter resin, clean IPA |

| Learning Resources | Extensive, beginner-friendly | Technical, chemistry-focused |

Real-World Example: Sarah’s First 3D Printer Journey

Sarah, a high school teacher interested in making educational models, bought a mid-range resin printer based on online reviews praising its “incredible detail.” She was excited—until she opened the box.

She struggled to level the build plate. Her first print failed because the first layer didn’t adhere. She poured too much resin, making it hard to seal the vat. When she tried to clean the failed print, she didn’t wear gloves and developed a rash. The smell of IPA filled her small apartment, prompting complaints from her roommate.

After three weeks and five failed prints, she gave up and sold the printer at a loss. Later, she tried an entry-level FDM printer. Within two days, she printed a working pencil holder. A week later, she made a scale model of the human heart for her biology class. “I wish I’d started with FDM,” she said. “It just makes sense. Resin felt like chemistry lab—not creative prototyping.”

Step-by-Step Guide: Choosing Your First Printer

Follow this decision framework to determine which technology suits your situation best:

- Assess your workspace: Do you have a dedicated, ventilated area away from children and pets? If not, resin is risky.

- Define your goals: Are you printing functional tools, toys, or household items? → FDM. Miniatures, dentistry, or high-detail art? → Resin.

- Budget for total cost: Include materials, safety gear, cleaning supplies, and potential replacements (FEP films, vats).

- Evaluate your comfort with chemicals: If handling solvents and toxic liquids makes you uneasy, FDM is clearly safer.

- Test community support: Search Reddit, Facebook groups, or Discord for common issues with specific models. FDM communities are larger and more beginner-oriented.

Frequently Asked Questions

Can a complete beginner successfully use a resin printer?

Yes, but with caveats. Success requires strict adherence to safety protocols, patience with calibration, and willingness to learn chemical handling. Many beginners succeed only after switching from FDM or receiving mentorship.

Is FDM outdated compared to resin?

No. FDM remains the most widely used 3D printing technology in industry and hobbyist circles. Advancements in hotends, motion systems (e.g., CoreXY), and slicer software have dramatically improved speed and quality. It’s evolving, not obsolete.

Do I need to sand FDM prints to make them look good?

Not necessarily. Using fine layer heights (0.1mm), proper cooling, and techniques like vase mode or bridging optimization can yield excellent results. Sanding helps, but many functional prints don’t require cosmetic finishing.

Final Verdict: Which Is Actually Easier?

The evidence points clearly to FDM as the more beginner-friendly option.

It’s not just about technical simplicity. It’s about psychological momentum. FDM allows quick wins—printing a simple object the same day you set up the machine. That immediate feedback loop builds confidence and encourages experimentation.

Resin printing, while powerful, demands precision, discipline, and investment in safety infrastructure. Its rewards are higher fidelity, but the path to those rewards is longer and riskier for someone just starting out.

If your goal is to learn 3D printing fundamentals—design, slicing, troubleshooting, iteration—FDM provides a forgiving, accessible platform. Once you’ve mastered core concepts, transitioning to resin becomes far easier. But starting with resin often leads to burnout, wasted materials, and abandoned projects.

Conclusion: Start Simple, Scale Smart

Technology tempts us with shiny promises. Resin printers dazzle with flawless surfaces and microscopic details. But for beginners, the most important feature isn’t resolution—it’s reliability, safety, and simplicity.

FDM delivers that. It’s the proven gateway into the world of additive manufacturing. You’ll make mistakes, yes—but those mistakes won’t cost you in hazardous spills or medical concerns. You’ll learn faster, print more, and stay engaged longer.

Master FDM first. Understand bed adhesion, filament behavior, and slicer settings. Then, if high-detail work calls to you, add a resin printer to your toolkit—with knowledge, caution, and respect for its demands.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?