For tabletop gamers, model collectors, and miniature enthusiasts, 3D printing has revolutionized the way custom pieces are created. Whether you're crafting a one-of-a-kind warlord or replacing a lost pawn, having a printer at home puts limitless design power in your hands. But when it comes to choosing between resin and filament (FDM) printers, especially for small-scale models like miniatures, the decision isn’t always straightforward. Resin printers offer stunning detail, but they come with a reputation for being messy—and potentially intimidating for newcomers. So, is resin really too messy for beginners? Let’s break down the realities of both technologies and help you decide which path suits your goals, workspace, and comfort level.

Detailed Output: Resin Wins on Fidelity

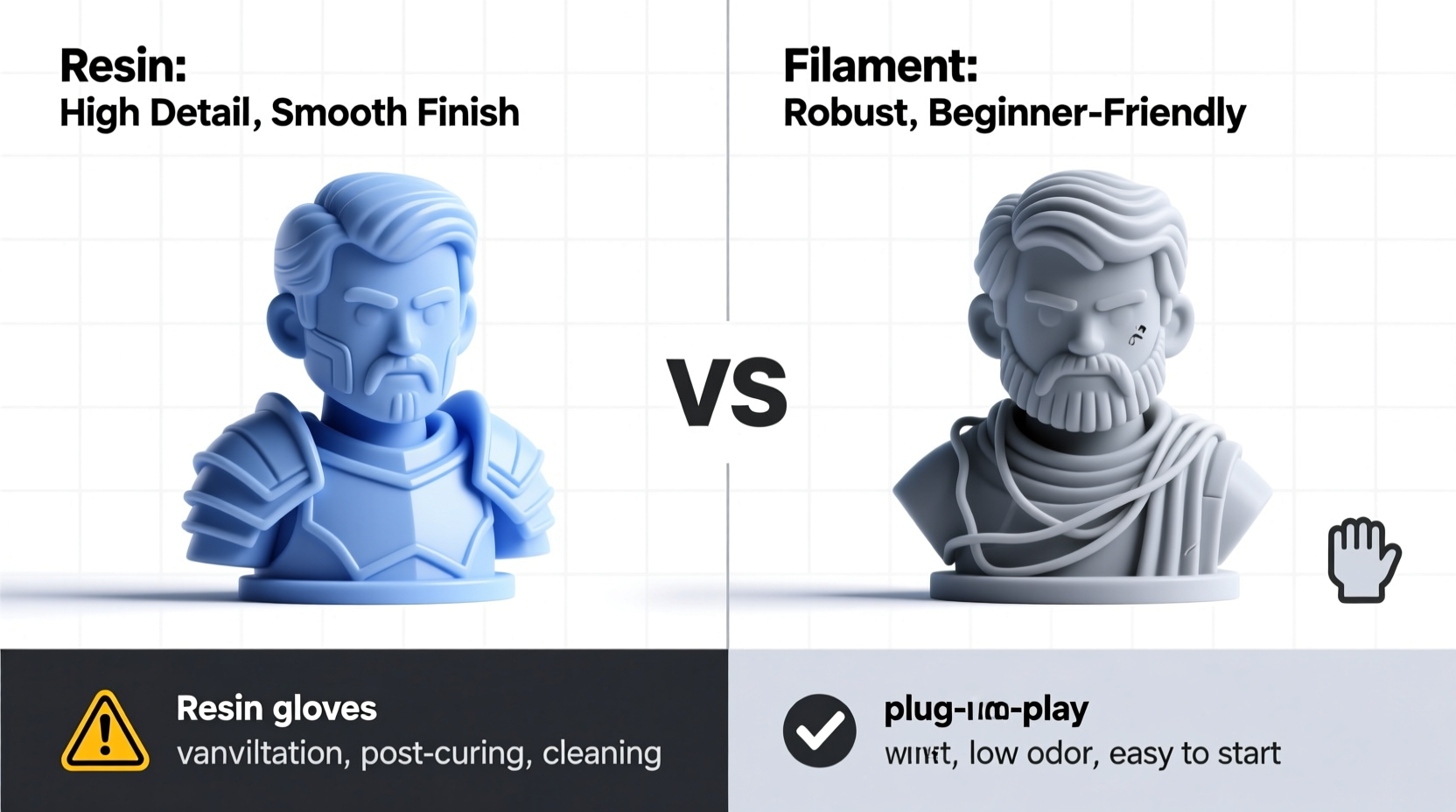

When printing miniatures—especially those under 50mm tall—surface detail is everything. Facial expressions, armor engravings, weapon textures, and fine hair strands can make or break immersion. This is where resin printers shine. Using a process called stereolithography (SLA) or digital light processing (DLP), resin printers cure liquid photopolymer layer by layer with UV light. Because the laser or projector can achieve resolutions as fine as 35 microns (compared to typical 100–200 microns on FDM), the resulting prints capture intricate geometry that filament simply cannot replicate consistently.

Filament printers build models by extruding melted plastic through a nozzle. While modern machines have improved significantly, visible layer lines, stringing, and nozzle artifacts often require extensive post-processing to clean up. For miniatures, this means sanding delicate features risks damaging them. In contrast, resin prints emerge smooth and crisp, needing only minimal cleanup before painting.

The Mess Factor: What “Messy” Really Means

Critics of resin printing often cite mess as the primary drawback. And yes, handling liquid resin requires care. Unlike filament, which is essentially plug-and-play, resin involves direct contact with chemicals. Uncured resin is sticky, smelly, and potentially hazardous if not managed properly. Spills happen, vats leak, and failed prints can leave gooey residues inside the build chamber.

But calling resin \"too messy\" oversimplifies the issue. The mess isn't random—it's predictable and containable with proper workflow and equipment. Most of the perceived chaos stems from poor preparation, not inherent flaws in the technology. With gloves, dedicated tools, and a clean workspace, the entire process becomes manageable, even for beginners.

In contrast, filament printers produce waste in different forms: oozing nozzles, tangled spaghetti failures, and microplastic dust from sanding. These aren’t necessarily cleaner—they’re just messes we’ve normalized over time.

“Resin isn’t inherently dangerous or unmanageable. It’s chemistry, not witchcraft. Treat it with respect, not fear.” — Dr. Lena Torres, Materials Scientist & 3D Printing Consultant

Comparing Workflows: Setup, Print, and Post-Processing

Understanding how each printer functions end-to-end helps clarify where effort and risk lie. Below is a side-by-side breakdown of key stages:

| Stage | Filament (FDM) | Resin (SLA/DLP) |

|---|---|---|

| Setup Time | Low – Load spool, level bed, start print | Moderate – Fill vat, check peel settings, clean optics |

| Print Quality | Good for larger items; layer lines visible on small details | Excellent – high resolution, smooth surfaces |

| Failure Rate | Moderate – warping, adhesion issues common | Higher initially – sensitive to calibration and exposure |

| Post-Processing | Sanding, priming, gap filling often needed | Washing in IPA, curing under UV, supports removal |

| Safety Concerns | Heat, moving parts, minor fumes (with ventilation advised) | Chemical exposure (resin/IPA), UV light, skin contact risk |

| Beginner Friendliness | High – intuitive, forgiving, widely supported | Moderate – steeper learning curve but very learnable |

While filament wins on simplicity, resin demands more deliberate steps—but also rewards precision. Beginners can succeed with resin, provided they approach it methodically.

A Realistic Beginner Journey: Sarah’s First Miniature Prints

Sarah, a board game enthusiast with no prior 3D printing experience, wanted to create custom dungeon tiles and unique NPCs for her D&D campaign. She researched both options and opted for a mid-range resin printer based on online recommendations for detail quality. Her first week was rocky: she spilled resin on her desk, forgot to wear nitrile gloves once (resulting in mild skin irritation), and had two failed prints due to incorrect exposure settings.

But by her third week, she’d established a routine. She set up a dedicated printing station with trays, gloves, and isopropyl alcohol (IPA) in sealed containers. She joined a Discord group where users shared slicer profiles and troubleshooting tips. By month’s end, she was producing gallery-quality miniatures, complete with flowing cloaks and engraved insignias—details that would have been impossible with her old filament machine.

Sarah’s story reflects a common trajectory: initial frustration followed by rapid improvement once systems are in place. The mess didn’t disappear—but it became part of a controlled process.

Safety and Best Practices for Resin Newcomers

The perception that resin is “too messy” often ties into safety concerns. Uncured resin is a sensitizer—repeated exposure can lead to allergic reactions. IPA, used for washing prints, is flammable and irritating to eyes and lungs. However, these risks are mitigated with standard lab practices:

- Always wear nitrile gloves (latex won’t protect against resin).

- Work in a well-ventilated area; consider an exhaust fan or air purifier.

- Use dedicated tools—never kitchen utensils—for handling resin.

- Store resin bottles upright in a cool, dark place, away from children and pets.

- Cure prints fully before sanding or handling bare-handed.

Step-by-Step: Safe Resin Printing Routine for Beginners

- Prepare Your Workspace: Cover surfaces with disposable paper or silicone mats. Have gloves, goggles, and IPA ready.

- Load the Vat: Pour resin slowly into the vat, avoiding bubbles. Wipe excess with a lint-free cloth.

- Start the Print: Ensure the build plate is calibrated. Monitor the first few layers for adhesion.

- Remove the Print: After completion, use gloves to detach the build plate and remove the model.

- Wash the Model: Submerge in IPA for 5–10 minutes using a wash station or manual bath. Agitate gently.

- Cure the Print: Place on a turntable under a UV lamp for 5–10 minutes per side.

- Remove Supports: Use flush cutters and fine files to clean attachment points.

- Dispose of Waste Properly: Never pour uncured resin down the drain. Cure spills with UV light before disposal.

Following this sequence minimizes exposure and keeps your environment safe and organized.

When Filament Might Be the Smarter Choice

Despite resin’s advantages, filament remains a strong contender—especially for certain use cases. If you primarily print terrain, large bases, or modular scenery where fine detail matters less, FDM is durable, cost-effective, and easier to scale. PLA filament is non-toxic when printed in ventilated areas, and failed prints can be tossed in compost (if biodegradable) or recycled in some facilities.

Additionally, filament printers are generally quieter and don’t require chemical baths. For parents, educators, or those working in shared spaces, this can be a decisive factor. You can run an FDM printer in a living room with minimal disruption. Resin setups, by contrast, belong in garages, sheds, or dedicated hobby rooms.

Cost Considerations Over Time

Initial costs for entry-level resin and filament printers are similar—often between $200 and $400. But long-term ownership differs:

- Resin Printers: Require ongoing purchases of resin (~$30–50 per liter), IPA or alternative wash fluids, replacement vats (every 1–2 liters), and FEP films. Curing stations add $50–100.

- Filament Printers: Use spools costing $15–25 per kg. No special cleaning liquids needed. Maintenance focuses on nozzle replacements and belt tension.

While resin offers better detail, it’s more expensive per print. A single 30mm miniature might use $0.30 worth of resin versus $0.10 in PLA. But because resin prints rarely need rework, material efficiency evens out somewhat.

Checklist: Choosing the Right Printer for Miniatures

Answer these questions to guide your decision:

- Will I mostly print highly detailed figures under 60mm? → Lean toward resin.

- Do I lack a dedicated, ventilated space? → Lean toward filament.

- Am I comfortable wearing gloves and handling chemicals? → Resin is viable.

- Is my priority speed and reliability over perfection? → Choose filament.

- Do I plan to sell or display finished models? → Resin gives a professional edge.

- Am I on a tight budget for consumables? → Filament is cheaper long-term.

Frequently Asked Questions

Can I use a resin printer safely in my apartment?

Yes, but with precautions. Use low-odor resins, seal the printer if possible, and always work near open windows or with an air purifier. Avoid sleeping in the same room during and after prints until vapors dissipate.

Are there beginner-friendly resin printers?

Absolutely. Models like the Elegoo Mars 3, Anycubic Photon Mono X, and Phrozen Sonic Mini 4K are known for reliability, good community support, and user-friendly software. Many include built-in air filters and touchscreens to simplify operation.

Do I have to use isopropyl alcohol to wash prints?

IPA is most effective, but alternatives exist. Dedicated aqueous resin cleaners (like Form Wash or Ultraclean) are less flammable and safer for indoor use. Some users dilute with water, though effectiveness drops. Avoid acetone or ethanol—they can damage resins.

Conclusion: Embrace the Process, Not Just the Result

Resin printing isn’t inherently too messy for beginners—it’s just different. The idea that it’s reserved for experts is outdated. Today’s machines are more reliable, materials are safer, and communities are richer than ever. Yes, you’ll get resin on your fingers. Yes, you’ll ruin a few prints. But with basic discipline and protective gear, the risks are manageable, and the results speak for themselves.

If you value precision, love painting miniatures, and want to bring imaginative designs to life with museum-grade detail, resin is worth the learning curve. Start small, follow best practices, and treat each mistake as part of the craft. On the other hand, if you prioritize convenience, durability, and hassle-free operation, filament remains a capable and satisfying choice.

Ultimately, the best printer is the one you’ll use consistently. Don’t let fear of mess deter you from exploring what resin can do. Set up smart, stay safe, and let your creativity take shape—one layer at a time.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?