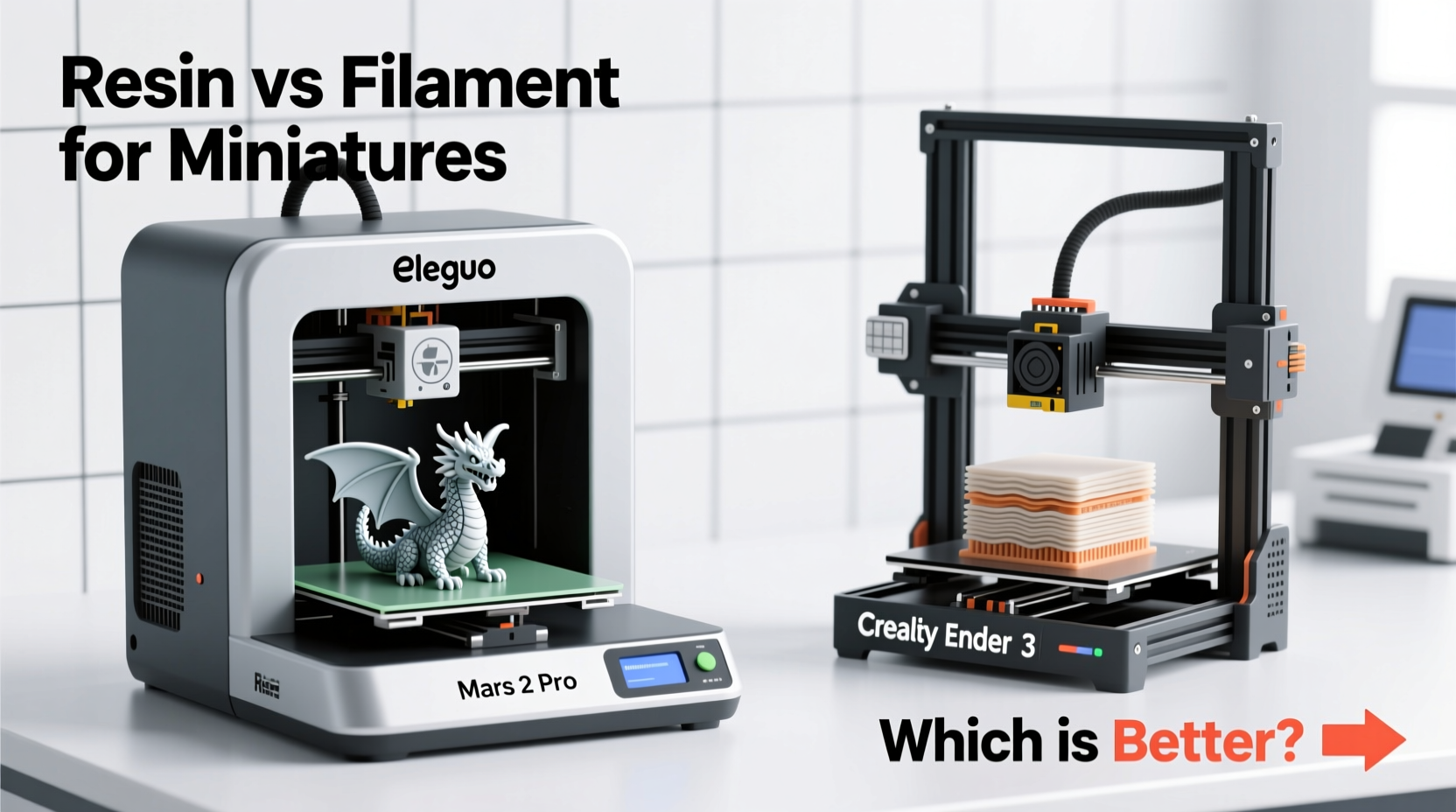

When it comes to 3D printing miniatures—whether for tabletop gaming, collectibles, or prototyping—the choice between resin and filament (FDM) printers isn’t just about preference. It’s a decision that affects print quality, post-processing effort, material costs, and long-term usability. Both technologies have evolved significantly, but they serve different needs. For miniature enthusiasts who demand fine detail, clean edges, and minimal layer artifacts, understanding the strengths and limitations of each system is essential.

Filament printers, also known as Fused Deposition Modeling (FDM) machines, build objects by extruding melted thermoplastic layer by layer. Resin printers, on the other hand, use liquid photopolymer resin cured by UV light in a process called stereolithography (SLA) or its variants like MSLA. The differences in these methods lead to stark contrasts in output, especially at small scales.

Detail Resolution and Surface Quality

For miniature printing, surface fidelity is paramount. Faces, armor engravings, weapon textures, and facial expressions must be rendered with clarity. Resin printers excel here due to their fundamentally higher resolution capabilities. Most consumer-grade resin printers offer XY resolutions between 35–50 microns, with layer heights as low as 10–25 microns. This allows for smooth curves, sharp corners, and intricate details invisible to filament printers.

Filament printers typically operate at 100–200 micron layer heights, even on high-end models. While some advanced FDM setups can go lower, nozzle size limits detail reproduction. A standard 0.4mm nozzle struggles to render features smaller than that diameter, leading to rounded edges and stair-stepping on curved surfaces. Even with optimal settings, FDM prints require significant sanding and filling to achieve a professional finish—especially on faces and delicate accessories.

In practice, this means a 28mm fantasy knight printed on a good resin printer will show individual rivets on armor, defined musculature, and readable inscriptions. The same model on an FDM printer may appear blurred or chunky without extensive post-processing.

Print Workflow and Post-Processing Requirements

While resin wins in raw detail, it demands a more involved workflow. After printing, resin models must be removed from the build plate, washed in isopropyl alcohol (IPA), and then post-cured under UV light. This extra equipment—wash station, curing chamber—adds both cost and complexity. IPA is flammable and requires ventilation; uncured resin is hazardous and must be handled carefully.

Filament printing is simpler in comparison. Once the print finishes, you remove it, clip off supports if needed, and it’s largely ready. No washing, no curing, no toxic liquids. However, support removal on FDM prints often leaves visible marks, and stringing or warping can ruin small parts. Supports are generally larger and more intrusive than those used in resin printing, where finer, more breakaway-style supports are possible due to the higher precision.

Another consideration is print failure recovery. Resin prints are fragile during peeling from the build plate. A failed peel can destroy a nearly finished model. FDM prints are more robust mid-print—if a layer shifts, the rest of the print might still be salvageable.

“With resin, you trade mechanical simplicity for optical perfection. You gain incredible detail but lose the ‘set it and forget it’ reliability of filament.” — Daniel Reeves, Miniature 3D Printing Specialist and Game Studio Modeler

Cost Comparison Over Time

The initial investment for both types can be similar, but long-term costs diverge. Entry-level resin printers start around $200–$300, while capable FDM printers begin at $180–$400. However, consumables tell a different story.

| Factor | Resin Printer | Filament Printer |

|---|---|---|

| Material Cost per Liter/Gram | $35–$60 per liter | $18–$30 per kg (PLA) |

| Support Equipment Needed | Wash station, curing station, gloves, ventilation | None required |

| Lifespan of Consumables | Resin degrades over time; vat membrane wears out (~6–12 months) | Nozzle replacements every 3–6 months depending on use |

| Waste Material | Supports + wash residue (uncurable waste) | Supports and stringing (recyclable PLA possible) |

Resin is more expensive per unit volume and generates hazardous waste. Unused resin left in the vat can cure prematurely if exposed to ambient light. In contrast, filament spools store indefinitely in dry conditions and produce minimal waste. PLA, the most common filament, is biodegradable under industrial conditions and widely recyclable.

Mini Case Study: Printing a Warhammer 40K Space Marine

Consider a hobbyist preparing to print a detailed Warhammer 40K Space Marine Captain. The model is 7cm tall with ornate armor, a flowing cape, and a plasma cannon. Using a Creality Ender 3 V2 (FDM), the user sets a 0.1mm layer height and 10% infill. After six hours, the print completes. Upon inspection, the cape shows noticeable layer lines, the face lacks definition, and the gun barrel has slight warping. Sanding and priming take another three hours before painting.

Using an Anycubic Photon Mono X (resin), the same model takes 90 minutes to print at 35-micron layers. After washing in IPA and 10-minute UV cure, the model emerges with crisp lines, no warping, and near-invisible layer bands. Support marks are minimal and easily sanded. Total post-processing time: 45 minutes.

Despite the longer setup and chemical handling, the resin version delivers superior accuracy and saves labor. For a single display piece, the effort is justified. But if the user plans to print 20 troops for an army, the cumulative time spent washing, curing, and managing resin becomes a bottleneck.

When Filament Makes Sense for Miniatures

Resin dominates in detail, but filament remains viable in specific scenarios. Hobbyists focused on durability—such as children’s toys or terrain pieces meant for heavy handling—benefit from the toughness of ABS or PETG. These materials resist impact far better than brittle resin prints.

Filament is also preferable for large-scale projects. Printing a dungeon diorama with walls, furniture, and environmental props favors FDM’s speed and structural strength. Resin would require multiple prints, careful alignment, and risk breakage during assembly.

Additionally, users prioritizing safety and simplicity—especially in homes with pets or young children—may avoid resin altogether. The need for chemical handling, UV exposure risks, and fumes makes resin less family-friendly.

- Filament is better when: Durability matters, budget is tight, workspace is limited, or printing large batches.

- Resin is better when: Detail is critical, models are display-focused, and post-processing time must be minimized.

Step-by-Step Guide: Choosing the Right Printer for Your Miniature Needs

- Define your primary use case: Are you printing for gaming (needs durability) or display (needs detail)?

- Assess your workspace: Do you have ventilation and storage for chemicals? Can you dedicate space to a wash/cure setup?

- Calculate your expected print volume: Will you print dozens of miniatures monthly, or a few special pieces per year?

- Evaluate your skill level: Are you comfortable handling hazardous materials and troubleshooting delicate prints?

- Budget for total ownership: Include printer, materials, safety gear, and maintenance (e.g., replacement FEP films, resin vats).

- Test sample models: Print the same miniature file on both technologies (via a friend or service) to compare results firsthand.

- Make your decision: Choose resin for unmatched detail and finish; choose filament for practicality, safety, and cost efficiency.

FAQ

Can I paint resin and filament miniatures the same way?

Yes, both accept acrylic paints well. However, resin prints require thorough cleaning and full curing before painting to ensure proper adhesion. Primer is recommended for both, but resin holds primer more smoothly due to its flat surface.

Is resin printing dangerous?

Uncured resin is a skin and respiratory irritant. Proper PPE—gloves, mask, eye protection—and ventilation are essential. Once fully cured, resin prints are safe to handle. Avoid inhaling fumes during printing and never touch uncured resin bare-handed.

Do filament printers ever match resin detail?

Not realistically. Even with micro-extrusion systems or dual-nozzle setups, FDM cannot reproduce sub-100-micron features consistently. Some experimental setups approach resin-like quality, but they are slow, finicky, and not mainstream.

Checklist: Ready to Choose Your Miniature Printer?

- ☐ I understand the difference in detail quality between resin and FDM.

- ☐ I’ve considered my workspace and safety requirements.

- ☐ I’ve compared long-term material and maintenance costs.

- ☐ I know how much time I’m willing to spend on post-processing.

- ☐ I’ve tested or seen sample prints from both technologies.

- ☐ I’ve selected a model based on my priorities: detail (resin) or practicality (filament).

Conclusion: Precision Wins, But Practicality Matters

For pure miniature printing quality, resin is objectively superior. Its ability to capture microscopic detail, reduce layer visibility, and minimize post-work makes it the preferred choice for serious hobbyists and professionals. If your goal is museum-quality figures, competition-level paint jobs, or accurate reproductions, resin is worth the investment and learning curve.

Yet, filament retains strong advantages: lower operating costs, safer operation, greater durability, and faster turnaround for bulk printing. For gamers building armies, educators creating classroom models, or makers valuing simplicity, filament remains a smart, sustainable option.

The best choice depends not on which technology is “better” overall, but which aligns with your goals, environment, and commitment level. Evaluate your needs honestly, respect the trade-offs, and choose accordingly.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?