A nail gun is one of the most efficient tools in construction and woodworking, drastically reducing labor time while increasing precision. However, like any power tool, its performance depends on proper loading, regular maintenance, and adherence to safety protocols. A poorly maintained or incorrectly loaded nail gun can misfire, jam, or even cause serious injury. This guide walks you through every critical step—from safe loading procedures to routine care—ensuring your nail gun operates at peak efficiency for years.

1. Understanding Your Nail Gun Type and Ammunition

Before loading or operating a nail gun, it’s essential to know which type you’re using. The two most common varieties are pneumatic (air-powered) and cordless electric models. Each accepts specific nail types, usually in strips, coils, or sticks. Using the wrong fasteners leads to jams, inconsistent driving depth, or internal damage.

Pneumatic nail guns require compatible air pressure (measured in PSI), typically between 70–120, depending on the model. Cordless models rely on battery power and internal motors calibrated for certain nail dimensions. Always consult your user manual to confirm:

- The correct nail gauge (e.g., 15°, 16°, 18° angle)

- Nail length range (commonly 1\" to 3½\")

- Fastener head type (full-round, clipped, or offset)

- Strip vs. coil compatibility

“Using incorrect nails is the leading cause of premature wear in nail guns. Match the fastener to the tool—not the other way around.” — James Rourke, Industrial Tool Maintenance Supervisor

2. Step-by-Step Guide to Safely Load Your Nail Gun

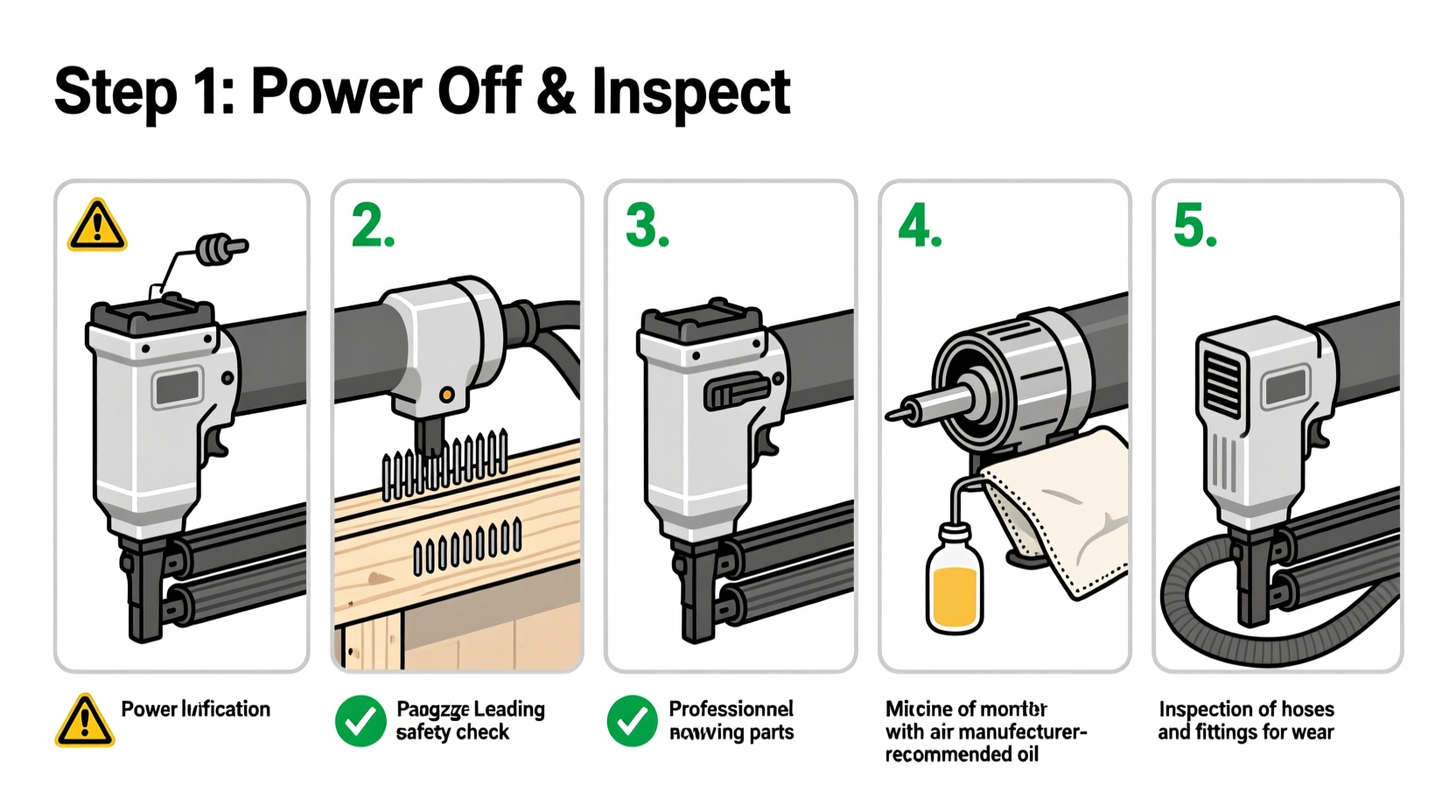

Loading a nail gun seems straightforward, but skipping steps increases the risk of accidental discharge or misfeeds. Follow this sequence for safe, reliable loading:

- Disconnect the power source: For pneumatic models, disconnect the air hose. For cordless units, remove the battery. Never attempt to load under pressure.

- Engage the safety lock: If your model has a trigger lock, activate it to prevent unintentional firing.

- Open the magazine: Locate the release lever or sliding mechanism. Slide it open smoothly—do not force it if resistance occurs.

- Insert the nail strip correctly: Align the strip so that nails feed into the driver channel nose-first. Ensure the strip sits flat and fully seated. Some models have guides; use them.

- Close and secure the magazine: Push the cover shut until it clicks. Test gently to ensure it won’t open during operation.

- Reconnect power source: Reattach the air hose or battery only after confirming the tool is fully loaded and clear of obstructions.

- Dry-fire test (optional): In a safe direction, pull the trigger once without material present to verify feeding mechanism function.

Never point the nail gun at yourself or others during loading. Treat it as loaded even when empty.

3. Routine Maintenance for Long-Term Performance

Regular maintenance prevents costly repairs and extends tool life. Dust, debris, and moisture accumulate inside the driver blade, magazine rails, and O-rings, leading to friction and corrosion. Below is a recommended maintenance schedule based on usage frequency.

| Maintenance Task | After Every Use | Monthly (Light Use) | Every 10,000 Nails (Heavy Use) |

|---|---|---|---|

| Clean exterior and nose | ✅ | ✅ | ✅ |

| Lubricate driver blade (pneumatic) | ✅ | ✅ | |

| Inspect O-rings and seals | ✅ | ✅ | |

| Check for nail jam residue | ✅ | ✅ | ✅ |

| Replace worn parts (nose piece, spring) | ✅ |

To clean the interior, disengage all power sources and use a soft brush or compressed air to remove sawdust and metal shavings. Apply a few drops of pneumatic tool oil to the driver blade weekly if used frequently. Avoid over-lubrication, which attracts grime.

4. Real-World Example: Preventing Costly Downtime

Carlos Mendez, a framing contractor in Oregon, once lost an entire workday due to a seized driver blade on his framing nailer. He had skipped oiling for three weeks during a busy season. “The tool just stopped firing,” he recalls. “I thought it was the compressor, but it turned out the piston was gummed up with old grease and dust.”

Since then, Carlos implemented a mandatory end-of-day maintenance checklist for his crew. They now spend five minutes cleaning and oiling each tool. As a result, equipment downtime dropped by 70%, and nail gun replacements decreased from two per year to one every three years. “Five minutes a day saves us hundreds in repairs and delays,” he says.

5. Common Mistakes and How to Avoid Them

Even experienced users make errors that compromise safety and performance. Here are frequent pitfalls and their solutions:

- Forcing a jammed nail: Never pry out a stuck nail with a screwdriver while the tool is pressurized. Depressurize first, then carefully disassemble the nose to remove fragments.

- Using damaged nail strips: Bent or warped strips cause misfeeds. Discard dented or kinked fasteners before loading.

- Ignoring manufacturer torque specs: Over-tightening housing screws during maintenance can crack casings. Use a calibrated screwdriver when reassembling.

- Storing the tool with nails loaded: Residual spring tension wears out the feeder mechanism. Always unload before storage.

Do’s and Don’ts Summary

| Action | Do | Don't |

|---|---|---|

| Loading | Always disconnect power first | Load while connected to air or battery |

| Cleaning | Use dry compressed air and soft brushes | Soak internal components in solvent |

| Storage | Unload, clean, and store in dry case | Leave nails inside or expose to humidity |

| Operation | Wear safety goggles and hearing protection | Work without PPE or fire blindly into walls |

6. Frequently Asked Questions

How often should I lubricate my pneumatic nail gun?

For average use (a few hundred nails per session), apply 3–5 drops of pneumatic tool oil into the air inlet every two days. Heavy users should oil before each shift. Electric models generally require less lubrication—refer to your manual.

What causes double-firing in sequential-trip nail guns?

Double-firing often results from worn sear mechanisms or excessive trigger sensitivity. It can also stem from using low-quality nail strips with inconsistent spacing. Regular inspection and high-grade fasteners reduce this risk.

Can I use the same nail gun for framing and finish work?

No. Framing nailers drive large, structural fasteners (16d–10d) and operate at higher impact force. Finish nailers use smaller gauges (15–18) and shallower depths. Using a framing gun on trim will split wood and damage surfaces. Invest in specialized tools for each task.

Final Checklist: Safe Loading & Maintenance Routine

- ☑ Disconnect air hose or battery before loading

- ☑ Verify correct nail type and length

- ☑ Clean magazine rails weekly

- ☑ Lubricate driver blade as needed

- ☑ Inspect O-rings and seals monthly

- ☑ Store unloaded in a dry, temperature-controlled environment

- ☑ Replace worn parts promptly

Conclusion

A well-maintained nail gun is safer, more accurate, and far more durable than one subjected to neglect. By following these practical steps—correct loading, consistent cleaning, and proactive part replacement—you protect both your investment and your worksite safety. Whether you're a weekend DIYer or a full-time carpenter, disciplined tool care pays dividends in reliability and performance. Make maintenance non-negotiable, just like wearing your safety gear.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?