A properly functioning pressure washer delivers consistent, high-pressure cleaning power. At the heart of this performance lies a small but critical component: the unloader valve. This often-overlooked part regulates water flow and pressure when the trigger is released, preventing damage to the pump and maintaining system stability. When misadjusted, the unloader valve can cause erratic pressure, overheating, or premature wear. Learning how to adjust it correctly ensures peak efficiency, extends pump life, and improves safety during operation.

Understanding the Unloader Valve’s Role

The unloader valve acts as a pressure relief mechanism. When you release the spray gun trigger, water stops flowing forward, but the pump continues running. Without an unloader, pressure would build uncontrollably, damaging hoses, seals, and internal components. The unloader redirects water back to the inlet or bypass line, allowing the pump to cycle safely while idle.

There are two main types: adjustable spring-style unloaders and fixed factory-set models. Most consumer and commercial-grade pressure washers use spring-loaded versions with an external adjustment knob or bolt. These allow fine-tuning of the working pressure and response time.

“Proper unloader valve calibration isn’t just about power—it’s about protecting your investment. A poorly adjusted valve can overheat a pump in under 10 minutes.” — Greg Holloway, Industrial Pump Technician with 25 years of experience

When to Adjust the Unloader Valve

Adjustment isn't needed daily, but certain signs indicate it's time to check:

- Pressure drops significantly when the trigger is pulled

- Pump cycles loudly or surges when idle

- Water leaks from the valve housing or relief port

- The motor strains or stalls upon trigger release

- You’ve changed nozzles frequently and notice inconsistent spray force

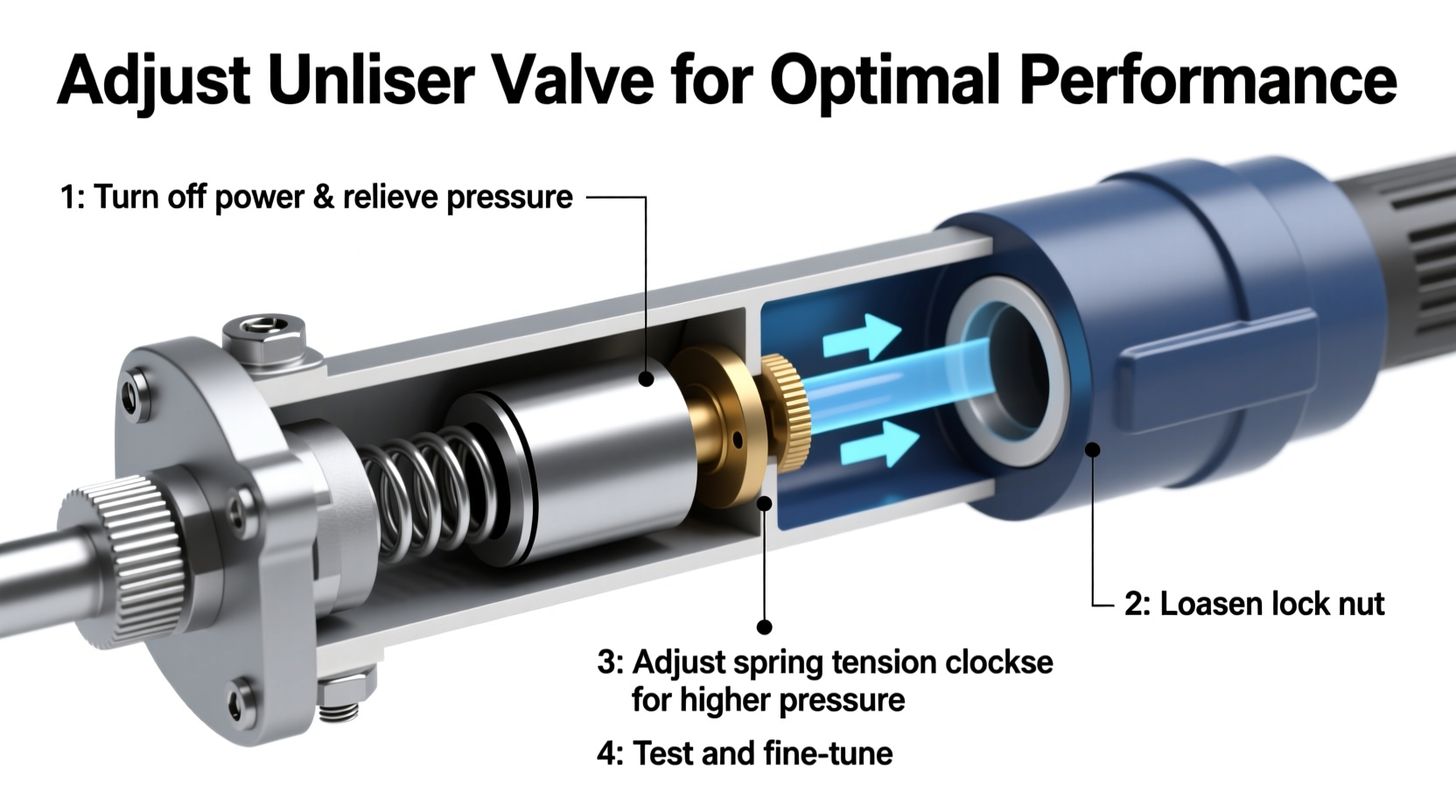

Step-by-Step Guide to Adjusting the Unloader Valve

Follow this sequence carefully to achieve optimal settings without risking damage.

- Turn off and disconnect the pressure washer. Shut down the engine or unplug the unit. Close the water supply and disconnect the hose.

- Locate the unloader valve. It’s typically mounted near the pump outlet, with a threaded knob or hex bolt on top. Refer to your manual if uncertain.

- Reconnect water supply and turn it on. Ensure steady flow into the inlet side to prevent cavitation during testing.

- Start the machine and let it run at idle. Do not pull the trigger yet. Observe baseline behavior—listen for unusual noises or vibrations.

- Pull the trigger and note pressure response. Use a downstream pressure gauge if available. Ideal operating PSI should match your nozzle rating (e.g., 3000 PSI for a red 0° tip).

- Release the trigger and watch for cycling. If the pump surges or makes a hammering sound, the valve may be too tight.

- Adjust the regulating screw. Turn clockwise (in) to increase pressure and restrict bypass flow. Turn counterclockwise (out) to reduce pressure and allow smoother recirculation.

- Make small adjustments—one-eighth to one-quarter turn at a time. Wait 10–15 seconds between changes to assess effect.

- Test after each adjustment. Pull and release the trigger multiple times. Aim for smooth transition between active spraying and idle recirculation.

- Finalize when stable. The pump should maintain steady pressure when firing and return to quiet bypass mode when released, without surging or leaking.

Tuning Tips During Adjustment

- If pressure feels weak even with full throttle, try tightening the valve slightly.

- If the machine vibrates violently when idle, loosen the valve to reduce backpressure.

- Never force the adjustment screw. Stripped threads can lead to costly repairs.

Do’s and Don’ts of Unloader Valve Maintenance

| Do’s | Don’ts |

|---|---|

| Use clean, filtered water to prevent debris buildup in the valve | Run the washer without water (dry-firing), which damages seals |

| Lubricate O-rings annually with silicone-based grease | Over-tighten the adjustment screw—this increases internal stress |

| Inspect the valve every 50 operating hours | Ignore signs of dripping or hissing at the relief port |

| Keep spare springs and seals on hand for quick replacement | Modify factory settings beyond recommended ranges without expert guidance |

Real-World Example: Fixing a Surging Commercial Unit

A landscaping contractor reported that his 3200 PSI cold-water pressure washer began pulsing erratically when idling. After ruling out clogged nozzles and low water supply, he inspected the unloader. The adjustment knob had loosened over time due to vibration. By turning it one-third turn clockwise and retesting, the pulsing stopped immediately. The pump now transitions smoothly between modes, reducing noise and operator fatigue. This minor fix saved him from unnecessary pump replacement and downtime.

Maintenance Checklist for Long-Term Performance

- ✅ Depressurize system before any inspection

- ✅ Locate and identify unloader valve type

- ✅ Check for visible leaks or corrosion

- ✅ Test idle and active pressure behavior

- ✅ Make incremental adjustments using proper tools

- ✅ Confirm smooth trigger response and quiet bypass

- ✅ Record final setting for future reference

Frequently Asked Questions

Can adjusting the unloader valve increase my pressure washer’s maximum PSI?

No. The unloader valve only regulates pressure within the limits set by the pump and motor. While fine-tuning can optimize delivery and consistency, it cannot exceed the machine’s designed output. For higher pressure, upgrade the pump or change to a smaller nozzle.

Why does my pressure washer leak water from the unloader when off?

Minor seepage after shutdown is normal due to thermal contraction and residual pressure. However, continuous dripping suggests worn seals or debris trapped in the valve seat. Disassemble and clean the valve, replacing damaged O-rings as needed.

How often should I service the unloader valve?

Inspect every 50 hours of use. Clean and lubricate internal components annually or every 200 hours, whichever comes first. More frequent maintenance is advised in hard-water areas or dusty environments.

Conclusion: Precision Leads to Performance

Adjusting the unloader valve is a simple yet powerful way to enhance your pressure washer’s reliability and cleaning effectiveness. With careful tuning, you prevent unnecessary strain on the pump, reduce noise, and ensure consistent spray power. Whether you're maintaining a residential unit or managing a fleet of commercial machines, mastering this skill pays dividends in longevity and operational efficiency. Small adjustments yield big results—take the time to get it right.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?