Building your own furniture doesn’t require years of woodworking experience or an elaborate workshop. A modern wooden stool is one of the most accessible entry points into DIY furniture making—functional, stylish, and surprisingly simple to construct. Whether you're looking to furnish a small space, practice basic carpentry, or simply enjoy the satisfaction of creating something with your hands, this guide walks you through every stage of assembling a clean-lined, minimalist stool from scratch. Designed specifically for beginners, the process uses common tools and straightforward techniques that deliver professional-looking results.

What You’ll Need: Tools and Materials

Before starting any build, preparation is key. Gathering all necessary components ensures a smooth workflow and prevents interruptions. Most materials can be sourced from a local hardware store or home improvement center. The design outlined here assumes a standard three-legged modern stool with a round seat and ¾-inch thick hardwood parts.

Materials List

- One 12” diameter x ¾” thick hardwood round (birch, oak, or maple)

- Three legs: 1.5” x 1.5” x 18” hardwood boards

- Six 2.5” wood screws

- Wood glue (water-resistant)

- 120- and 220-grit sandpaper

- Finish (tung oil, polyurethane, or wax)

Essential Tools

- Power drill with screwdriver bit

- Countersink bit (optional but recommended)

- Clamps (at least two)

- Tape measure and pencil

- Square (for alignment)

- Sander or sanding block

- Safety glasses and work gloves

Step-by-Step Assembly Process

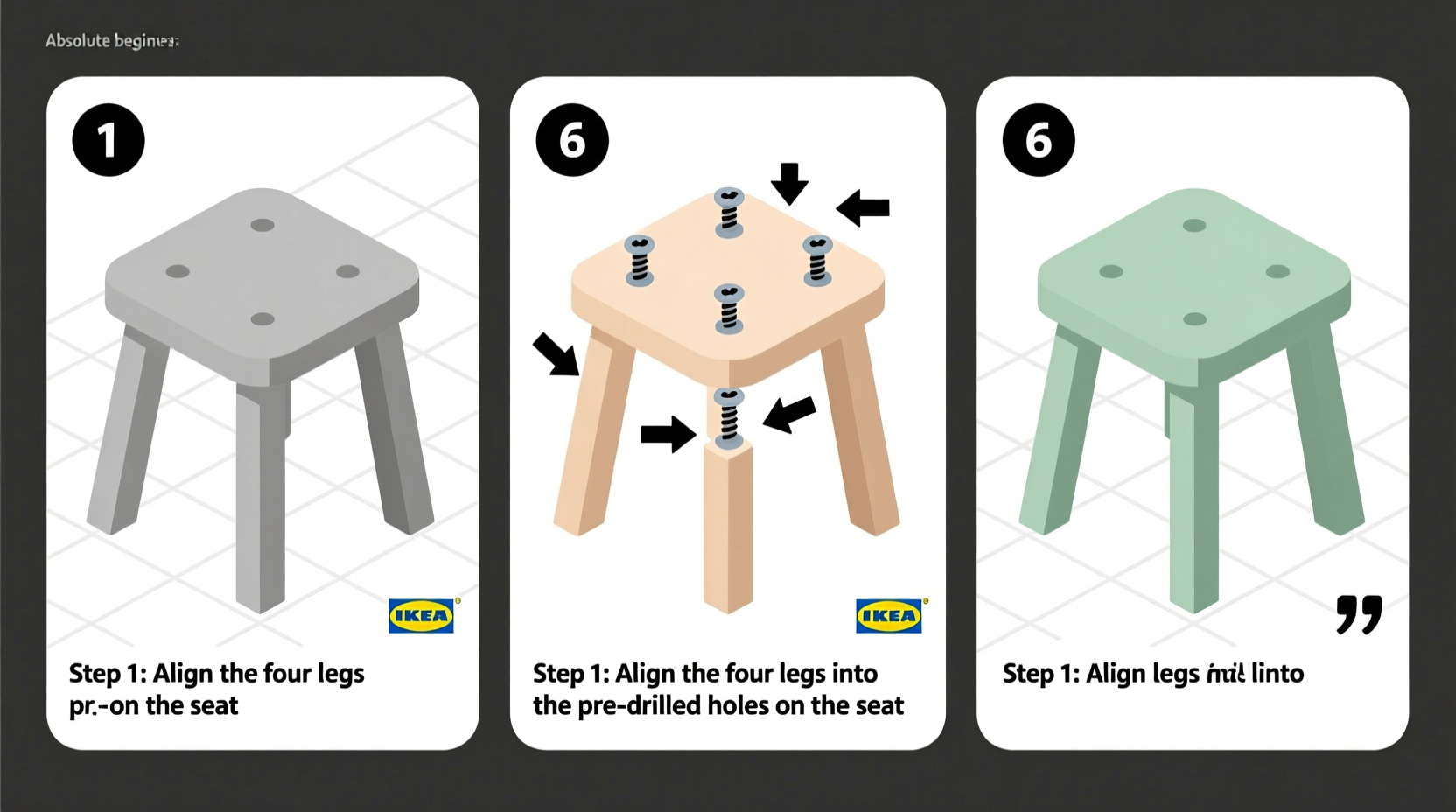

Follow this logical sequence to assemble your stool accurately and securely. Each step builds on the last, ensuring structural integrity and visual symmetry.

- Prepare and sand all components. Begin by smoothing the seat and each leg with 120-grit sandpaper, then progress to 220-grit for a refined finish. This removes rough edges and prepares the wood for final finishing after assembly.

- Mark leg positions on the underside of the seat. Use a compass or trace a small plate to find the center. From there, divide the circle into three equal sections (120 degrees apart). Measure 1” inward from the edge and mark where each leg will attach. Accuracy here ensures balanced weight distribution.

- Drill pilot holes. At each marked point, drill a pilot hole at a slight outward angle (about 10–15 degrees). This angled placement strengthens the joint and gives the stool a subtly flared base. Use a drill bit slightly smaller than your screws to prevent splitting.

- Apply wood glue to the top end of each leg. Spread a thin, even layer on the top ½ inch of each leg. Avoid excess glue, which can squeeze out and create a mess during clamping.

- Attach the legs using screws. Align each leg with its corresponding hole and insert a 2.5” screw through the seat into the leg. Use a countersink bit if you want flush-mounted screws. Repeat for all three legs, checking alignment with a square as you go.

- Clamp and let dry. Once all legs are secured, lightly clamp each leg-to-seat joint to ensure tight contact. Allow the glue to cure for at least 4 hours, preferably overnight, before handling.

- Final sanding and finishing. After drying, sand any uneven areas, especially around screw heads and joints. Wipe away dust with a tack cloth. Apply your chosen finish with a clean rag, following product instructions. Two coats typically yield best protection and depth.

| Step | Time Required | Difficulty Level |

|---|---|---|

| Preparation & Sanding | 30 minutes | Easy |

| Marking & Drilling | 25 minutes | Moderate |

| Assembly & Gluing | 20 minutes + drying | Easy |

| Finishing | 45 minutes (including drying between coats) | Easy |

Avoiding Common Beginner Mistakes

New woodworkers often make avoidable errors that compromise both appearance and durability. Recognizing these pitfalls early helps ensure a polished outcome.

- Skipping pilot holes: Driving screws directly into hardwood without drilling first increases the risk of splitting, especially near edges.

- Uneven leg placement: Misaligned legs cause wobbling. Always double-check spacing using measurements or a jig.

- Over-tightening screws: Excessive force can strip the wood or break the screw head. Apply steady, moderate pressure.

- Rushing the glue-up: Clamping too loosely or moving the stool too soon weakens the bond. Patience pays off in long-term stability.

Real Example: Sarah’s First Stool Build

Sarah, a graphic designer with no prior woodworking experience, decided to build a stool for her home office reading nook. She followed a version of this guide using pre-cut birch parts from a local lumber yard. Initially, she skipped pilot holes to save time and cracked one leg during installation. After replacing it and drilling proper guides, the second attempt succeeded. She applied two coats of satin polyurethane and now uses the stool daily. “I was nervous about power tools,” she said, “but once I took it slow and measured twice, everything clicked. Now I’m planning a matching side table.”

Expert Insight: Why Simple Design Matters

“Beginner projects should prioritize function and simplicity. A well-built stool teaches fundamental skills—measuring, joining, finishing—that apply to every future project. Don’t chase complexity; master the basics first.” — Marcus Tran, Furniture Maker & Workshop Instructor

Checklist: Assemble Your Stool Without Missing a Step

- Gather all materials and tools

- Sand all pieces before assembly

- Mark leg positions evenly spaced on seat

- Drill angled pilot holes

- Apply wood glue to leg tops

- Insert screws and secure legs

- Clamp joints and allow 4+ hours drying

- Sand final surfaces

- Apply protective finish (2 coats recommended)

- Let cure fully before use

Frequently Asked Questions

Can I build this stool without power tools?

Yes, though it will take longer. A hand drill and manual screwdriver can replace a power drill. However, pre-drilling pilot holes becomes even more critical to avoid splitting. Sanding by hand also works but requires more effort.

How much weight can this stool support?

A properly assembled stool using hardwood and wood glue can safely support up to 300 pounds. The three-leg design provides excellent balance on uneven floors, and the glued joints add significant strength beyond screws alone.

Is wood glue really necessary, or can I rely on screws only?

While screws provide immediate hold, wood glue creates a stronger, long-lasting bond by filling microscopic gaps between fibers. For furniture that lasts, always combine mechanical fasteners with adhesive. Glue alone isn't enough, but together, they form a durable joint.

Bring Craftsmanship Home: Start Building Today

There’s a quiet pride that comes from sitting on a stool you built yourself—one that no store-bought piece can replicate. This beginner-friendly project demystifies furniture making and equips you with transferable skills for larger builds. With minimal investment and a few focused hours, you’ve created not just a functional object, but a foundation for confidence in DIY craftsmanship. Choose your wood, clear a workspace, and begin. The next thing you build might just change how you see what you’re capable of.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?