The A-frame roof is an iconic design known for its simplicity, strength, and efficient water runoff. Commonly used in cabins, sheds, and modern minimalist homes, this steeply pitched triangular structure offers both aesthetic appeal and functional durability. However, constructing a reliable A-frame roof requires precision, proper materials, and adherence to structural best practices. This guide walks through every phase of the build—from planning to finishing—with actionable advice to ensure your roof stands strong against weather, time, and load.

Understanding the A-Frame Roof Design

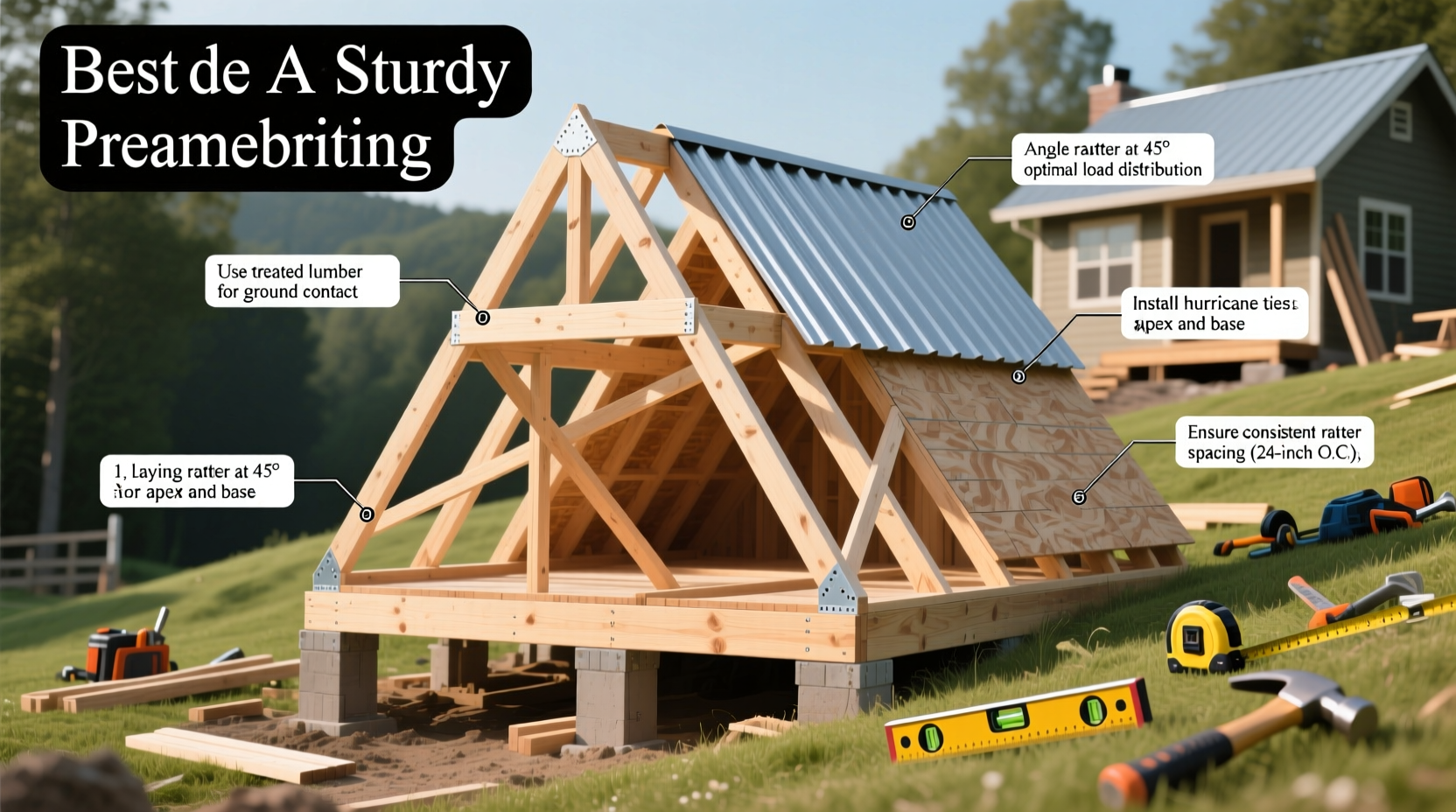

An A-frame roof consists of two symmetrical rafters that meet at the ridge, forming a triangle resembling the letter \"A.\" The steep pitch—typically between 30° and 60°—allows snow and rain to slide off easily, making it ideal for regions with heavy precipitation. Because the roof extends down to or near ground level in classic designs, interior space is limited but structurally stable due to inherent triangulation.

Unlike conventional roofs supported by horizontal ceiling joists, A-frames often rely on rigid connections at the ridge and base to resist outward thrust. This means connection points must be engineered carefully to prevent spreading under load. Proper understanding of load distribution—dead load (materials), live load (snow, wind), and lateral forces—is essential before cutting any lumber.

“Triangulation is nature’s strongest shape. When built correctly, an A-frame can withstand decades of harsh weather with minimal maintenance.” — Daniel Reeves, Structural Engineer & Timber Frame Specialist

Planning and Preparation: Laying the Foundation for Success

Before purchasing materials or lifting tools, invest time in accurate planning. Mistakes made during this stage are costly and difficult to correct later.

Determine Roof Pitch and Span

The span (distance between supporting walls) directly affects rafter size and spacing. For spans under 20 feet, standard 2x6 or 2x8 lumber may suffice. Larger spans require engineered trusses or additional support posts. A common pitch range is 45°–60°, balancing aesthetics with attic usability and material efficiency.

Choose Suitable Materials

- Rafters: Use #1 or Select Structural grade SPF (spruce-pine-fir) or Douglas fir for strength and straightness.

- Ridge Beam: Optional in true A-frames where rafters meet without a central beam, but recommended for wider spans to stabilize alignment.

- Fasteners: Galvanized or stainless steel nails/screws to resist corrosion.

- Sheathing: 7/16” or ½” OSB or plywood rated for roof use.

- Roofing: Metal panels, asphalt shingles, or cedar shakes depending on climate and budget.

Step-by-Step Construction Process

- Mark Wall Plates: Identify where rafters will sit on top plates. Ensure walls are level and square.

- Cut Rafters: Using a framing square, mark plumb cuts at the ridge end and seat cuts at the wall plate. Double-check angles with a protractor.

- Assemble First Pair: Lift the first two rafters into place and nail them temporarily. Brace vertically to keep upright.

- Install Ridge Board (Optional): If using, secure a continuous board along the peak. Not always needed if rafters are tightly joined and gusseted.

- Add Remaining Rafters: Space rafters 16” or 24” on center based on sheathing thickness and expected loads.

- Install Collar Ties (if needed): For wide spans, install horizontal ties between upper rafters to reduce outward pressure.

- Apply Sheathing: Begin at the eaves, staggering joints, and fastening with ring-shank nails or screws every 6 inches along edges and 12 inches in the field.

- Flash and Weatherproof: Install drip edge, ice-and-water shield along eaves, then roll out underlayment (felt or synthetic).

- Install Roofing Material: Follow manufacturer guidelines for shingles, metal, or other finishes.

| Component | Best Practice | Avoid |

|---|---|---|

| Rafter Spacing | 16” on center for heavy snow zones; 24” acceptable in mild climates with thicker sheathing | Irregular spacing or exceeding code-specified max |

| Connection Points | Use hurricane ties and structural screws for rafter-to-plate and rafter-to-ridge joints | Nailing alone without metal connectors |

| Sheathing Installation | Leave 1/8” gap between sheets to allow expansion | Butting panels tightly together |

| Pitch Consideration | Steeper pitches (>50°) improve shedding but increase wind uplift risk | Building too shallow a pitch in snowy areas |

Common Pitfalls and How to Avoid Them

Even experienced builders encounter issues when working with A-frame geometry. Awareness of frequent mistakes helps prevent costly rework.

- Incorrect Angle Cuts: A deviation of just 2° can cause gaps at the ridge. Always test-fit before mass production.

- Inadequate Bracing: Unbraced rafters can shift during assembly. Use temporary diagonal braces until sheathing is applied.

- Ignoring Local Codes: Snow load requirements vary significantly by region. Consult your municipality before finalizing plans.

- Poor Ventilation Planning: While traditional A-frames have little attic space, ventilation at the ridge and eaves remains important to prevent moisture buildup under roofing.

Real-World Example: Building an A-Frame Cabin in Vermont

In early spring, a homeowner in northern Vermont began constructing a 16’x20’ A-frame guest cabin. The region receives over 100 inches of snow annually, so structural integrity was paramount. After consulting local building codes, they selected 2x8 Douglas fir rafters spaced 16” apart with a 55° pitch.

They pre-assembled three rafter sections on the ground, using plywood gussets at the apex for added rigidity. Once lifted and secured to the log walls, temporary cross-bracing stabilized the frame. Sheathing followed immediately, locking the structure into place. By installing standing-seam metal roofing—a durable choice for snow shedding—they ensured long-term performance with minimal maintenance.

Despite high winds during construction, the braced system held firm. Two years later, the roof shows no signs of sagging or leakage, even after several severe winter storms.

Frequently Asked Questions

Can I build an A-frame roof without a ridge beam?

Yes, especially for smaller structures. True A-frames join rafters directly at the peak using metal plates or wooden gussets. Just ensure precise cuts and strong fastening to maintain alignment and strength.

How do I prevent the walls from pushing outward?

Outward thrust is countered by either a structural floor diaphragm (secured subfloor acting as a tension tie), collar ties installed high on the rafters, or integrated wall framing designed to resist lateral forces.

Is insulation possible in an A-frame roof?

Absolutely. With no traditional attic, insulation goes between rafters. Use rigid foam or spray foam to maximize R-value without compressing batt insulation. Always include a vapor barrier on the warm side to prevent condensation.

Final Checklist Before Closing In the Roof

- ✅ All rafters plumb and aligned at ridge

- Check with level and string line across peaks.

- ✅ Sheathing securely fastened with proper spacing

- No missed nails; gaps between panels accounted for.

- ✅ Flashing installed at valleys and edges

- Especially critical if joining to another roof section.

- ✅ Underlayment rolled and overlapped correctly

- Minimum 6” overlap in low slopes; more in high-wind areas.

- ✅ Final inspection passed (if required)

- Local building department sign-off ensures compliance.

Build Smart, Build Strong

Constructing a sturdy A-frame roof blends craftsmanship with engineering awareness. Every angle, fastener, and material choice contributes to the overall resilience of the structure. Whether you're building a backyard shed or a mountain retreat, attention to detail during layout, cutting, and assembly pays dividends in safety, longevity, and peace of mind. Now that you have the knowledge and practical steps, it's time to raise the frame—literally. Gather your tools, double-check your measurements, and start building something that will last for generations.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?