Brake shoes are a critical component of drum brake systems, commonly found on the rear wheels of many vehicles. Over time, friction material wears down, reducing stopping power and increasing braking distance. While many opt for professional service, replacing brake shoes at home is a feasible and cost-effective task—provided it's done correctly. With the right tools, preparation, and attention to detail, you can complete this job safely and efficiently in your driveway or garage.

Gather the Right Tools and Materials

Before starting, ensure you have all necessary equipment. Having everything ready prevents interruptions and keeps the workspace organized. Most of the tools are common in a standard mechanic’s toolkit, but specialty items like a brake spring tool may need to be purchased or borrowed.

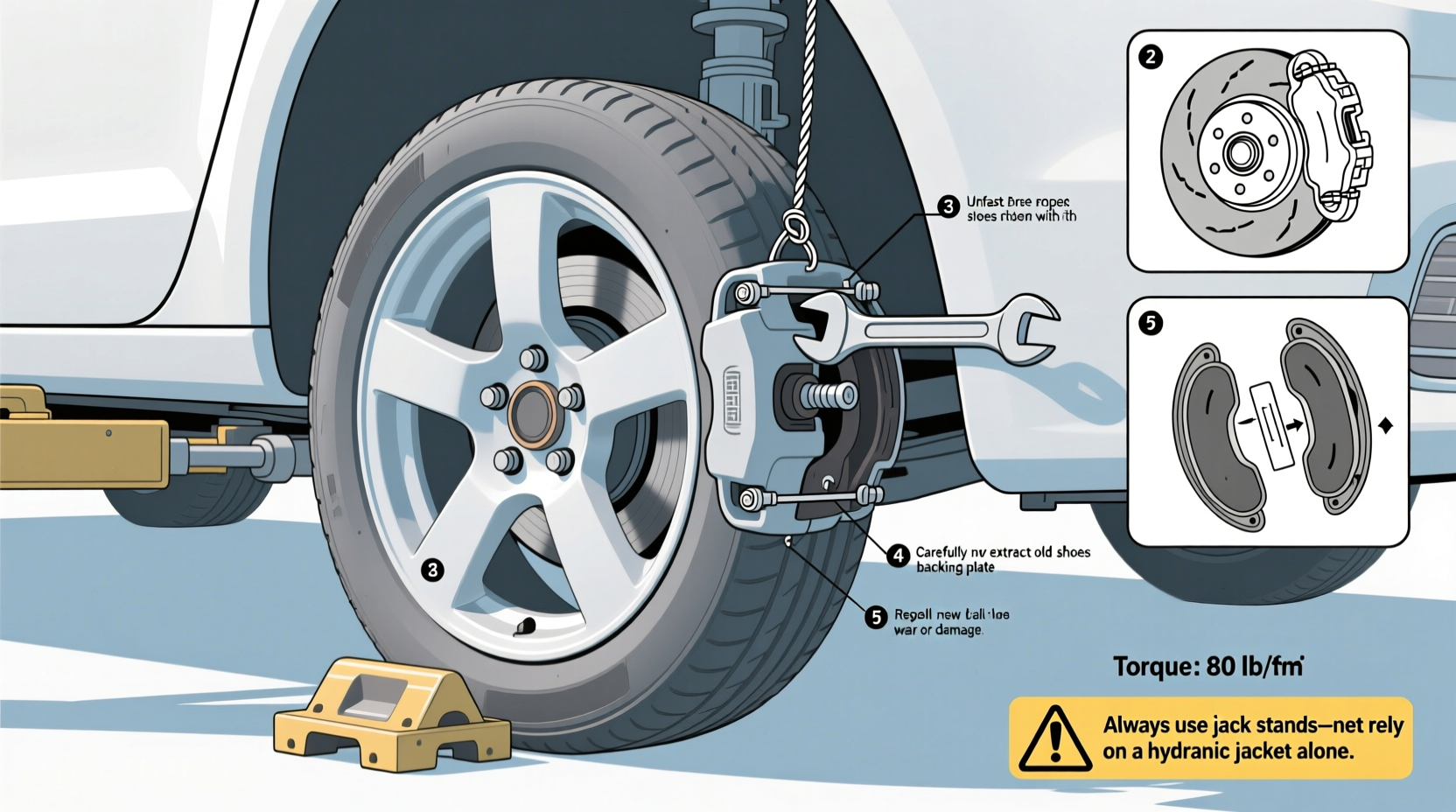

- Jack and jack stands (never rely solely on a hydraulic jack)

- Lug wrench or impact wrench

- C-clamp or brake caliper piston tool (for adjusting wheel cylinder)

- Brake spring tool set (specifically for drum brakes)

- Penetrating oil (e.g., WD-40 or PB Blaster)

- Wire brush and brake cleaner spray

- New brake shoes (ensure compatibility with your vehicle model)

- Brake grease (high-temperature, non-petroleum based)

- Flashlight or work light

- Rubber mallet

Safety First: Prepare Your Vehicle Properly

Safety is paramount when working under a vehicle. Always perform this work on a flat, stable surface. Engage the parking brake, block the front wheels, and never work under a car supported only by a jack.

- Park on level ground and turn off the engine.

- Place wheel chocks in front of and behind the front tires.

- Loosen the lug nuts slightly before lifting the vehicle.

- Use a floor jack to lift the rear of the vehicle and secure it with jack stands.

- Remove the rear wheels to expose the drum brake assembly.

If the brake drum is stuck due to rust or corrosion, apply penetrating oil around the hub and gently tap it with a rubber mallet. Rotate the drum while tapping to break the seal. Avoid using excessive force, which could damage components.

Step-by-Step Brake Shoe Replacement Process

Follow this sequence to replace brake shoes methodically and avoid mistakes.

- Remove the brake drum. After removing the wheel, inspect the drum for wear or cracks. If it comes off easily, proceed. If not, use the techniques mentioned above.

- Inspect the brake assembly. Look for leaking wheel cylinders, damaged springs, or excessive dust. Note any issues that may require additional repairs.

- Disconnect the parking brake cable. Use pliers to release the lever from the brake shoe. This allows full movement during removal.

- Remove return and hold-down springs. Using a brake spring tool, compress and detach the springs securing the shoes to the backing plate. Keep track of their positions.

- Take out the old brake shoes. Once springs are removed, carefully pull out both primary (front) and secondary (rear) shoes.

- Clean the backing plate. Use a wire brush and brake cleaner to remove rust, debris, and old grease. Do not use petroleum-based solvents near rubber components.

- Install new brake shoes. Position the new shoes onto the anchor points. Reattach springs using the brake spring tool. Ensure correct orientation—primary shoe faces forward.

- Lubricate contact points. Apply high-temperature brake grease to the shoe pads on the backing plate, adjuster mechanism, and parking brake lever. Avoid getting grease on friction surfaces.

- Adjust the brake shoes. Turn the star-wheel adjuster to expand the shoes until they lightly drag against the drum. You should hear a slight scraping sound when rotating the hub by hand.

- Reconnect the parking brake linkage. Reattach the cable to the lever on the secondary shoe.

- Reinstall the brake drum and wheel. Slide the drum back on. If it doesn’t fit, readjust the star wheel slightly. Torque lug nuts to manufacturer specifications once the vehicle is lowered.

“Improper brake shoe installation is one of the top causes of reduced braking efficiency in DIY repairs. Take your time—precision saves lives.” — Carlos Mendez, ASE-Certified Master Technician

Do’s and Don’ts During Brake Shoe Replacement

| Do’s | Don’ts |

|---|---|

| Wear safety glasses and gloves | Never reuse worn springs or hardware |

| Clean all metal-to-metal contact points | Don’t mix up primary and secondary shoe positions |

| Test brake adjustment before final reassembly | Don’t allow brake fluid or grease on friction surfaces |

| Double-check parking brake function | Don’t skip torquing lug nuts properly |

| Bleed the brakes if fluid was disturbed | Don’t drive at speed until brakes are bedded in |

Real-World Example: A Home Mechanic’s Experience

Mark, a DIY enthusiast from Ohio, decided to replace the rear brake shoes on his 2008 Toyota Corolla after noticing a grinding noise and increased pedal travel. He followed online guides but initially struggled with the stubborn drum. After applying penetrating oil and letting it sit for 20 minutes, he gently tapped the drum loose. During disassembly, he discovered a cracked return spring—one he hadn’t anticipated replacing. Thanks to his thorough inspection, he ordered a hardware kit and avoided a potential failure. After reassembly, he performed a slow test drive in a parking lot, gradually applying the brakes to seat the new shoes. The result? Smooth, quiet stops and over $200 saved compared to a shop quote.

This case illustrates how preparation and patience lead to success. Unexpected findings are common, so always inspect every component closely.

Frequently Asked Questions

How often should brake shoes be replaced?

Brake shoes typically last between 30,000 and 50,000 miles, depending on driving habits, load, and road conditions. Signs of wear include squealing, reduced responsiveness, or visible thinning of the friction material (less than 1/8 inch).

Can I replace brake shoes without adjusting the wheel cylinder?

No. The wheel cylinder must retract before installing new shoes. Use a C-clamp to gently push the piston back into place. Failure to do so can damage the cylinder or prevent proper shoe installation.

Is it safe to drive immediately after replacing brake shoes?

After replacement, drive cautiously for the first few miles. Perform several moderate stops from low speed to “bed in” the new shoes. Avoid hard braking until the friction material conforms to the drum surface.

Final Steps and Post-Replacement Checks

Once both sides are completed, lower the vehicle and torque the lug nuts to the manufacturer’s specification (usually 80–100 ft-lbs for most passenger cars). Start the engine and press the brake pedal firmly several times to position the shoes correctly. Check for even engagement and no dragging noises.

Take a short test drive in a safe area. Pay attention to:

- Brake feel (should be firm, not spongy)

- Any unusual noises (grinding, scraping, squealing)

- Parking brake effectiveness

- Vehicle pulling to one side during braking

If any issues arise, re-inspect the affected side. Spongy pedals may indicate air in the lines—bleeding the brakes will resolve this.

Conclusion: Confidence Through Knowledge

Changing brake shoes at home isn't just about saving money—it's about understanding your vehicle and taking control of its maintenance. With the right approach, even complex tasks become manageable. By following this guide, respecting safety protocols, and using quality parts, you ensure your vehicle stops as reliably as it runs.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?