Air pumps are essential in various applications—from aquariums and wastewater treatment to pneumatic systems and industrial processes. One often overlooked but critical component that ensures long-term efficiency and reliability is the check valve. When properly installed, a check valve prevents backflow, reduces wear on the pump, and maintains consistent system pressure. Without it, water or air can flow backward into the pump when it shuts off, leading to damage, reduced output, and even premature failure.

This comprehensive guide walks through the process of selecting, preparing, and installing a check valve on an air pump. Whether you're maintaining a home aquarium or managing an industrial aeration system, following these steps will help optimize your setup for peak performance and durability.

Why a Check Valve Matters

A check valve allows airflow in one direction only. Once the air pump stops, the valve closes automatically, preventing water or pressurized air from reversing into the pump mechanism. This is especially important in submerged or high-pressure environments where back-siphoning can occur.

Backflow causes several issues:

- Pump flooding: Water entering the pump can corrode internal components.

- Reduced efficiency: Air loss during shutdown means the pump must work harder to re-pressurize the system.

- Noise and vibration: Reverse flow can create knocking or fluttering sounds in the tubing.

- Shortened lifespan: Repeated exposure to moisture and pressure fluctuations wears out diaphragms and seals faster.

“In over 15 years of servicing industrial aeration systems, I’ve seen more pump failures caused by missing or failed check valves than any other single factor.” — Marcus Tran, HVAC & Pneumatics Engineer

Selecting the Right Check Valve

Not all check valves are created equal. Choosing the correct type depends on your application, flow rate, pressure, and tubing size. Below is a comparison of common types used with air pumps:

| Type | Best For | Pressure Range | Installation Ease |

|---|---|---|---|

| In-Line Spring Check Valve | High-pressure systems, industrial setups | 5–15 PSI | Moderate (requires cutting tubing) |

| Duckbill Check Valve | Aquariums, low-pressure aeration | 1–3 PSI | Easy (slips onto tubing) |

| Swing Check Valve | Larger diameter pipes, wastewater | 3–10 PSI | Difficult (threaded connections) |

| Ball Check Valve | Precise control, medical or lab use | 2–8 PSI | Moderate |

For most residential or small-scale applications—like fish tanks or garden pond aerators—a duckbill or in-line spring check valve is ideal. Ensure the valve’s inner diameter matches your tubing size (common sizes: ¼”, 3/8”, ½”).

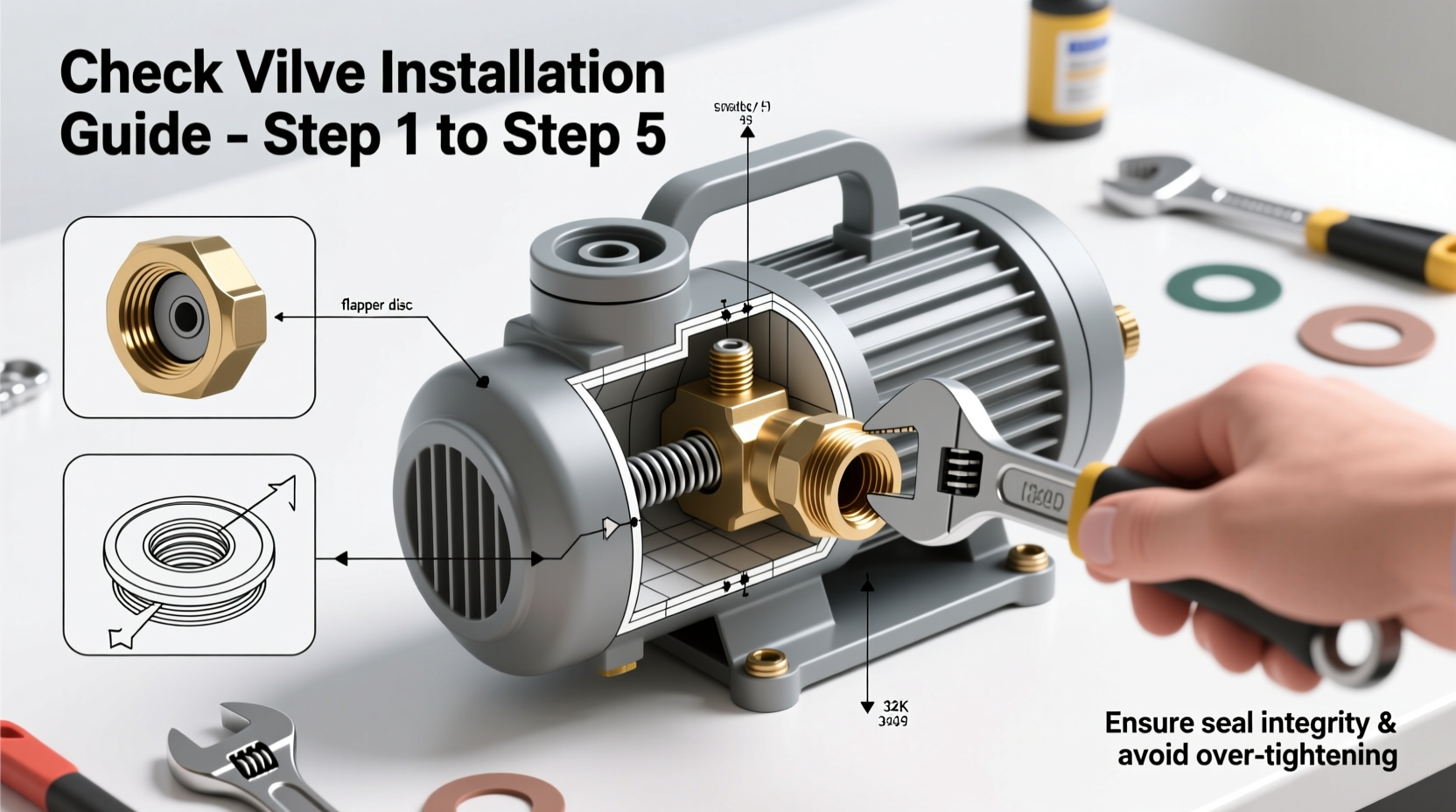

Step-by-Step Installation Guide

Follow this sequence to correctly install a check valve on your air pump. This process applies to both new installations and retrofits.

- Turn Off and Disconnect the Pump

Ensure the air pump is unplugged and fully depressurized. If connected to a submerged diffuser, allow time for water to drain back down the line. - Locate the Outlet Port

Identify the air outlet on the pump. Most units have clearly marked ports. Use a marker to label the outlet side if needed. - Cut the Tubing (If Required)

For in-line check valves, cut the airline tubing using clean, sharp scissors or a utility knife. Make a straight, perpendicular cut to ensure a snug fit. - Verify Flow Direction

All check valves have an arrow indicating the direction of airflow. This arrow must point away from the pump and toward the delivery end (e.g., aquarium or tank). - Install the Valve

- For duckbill valves: Slide the valve directly onto the tubing. Push firmly until fully seated.

- For in-line valves: Insert each end of the tubing into the valve connectors. Use hose clamps if recommended.

- Secure Connections

If using barbed fittings or compression connectors, gently tug on the tubing to confirm it won’t detach under pressure. Avoid over-tightening plastic fittings. - Test the System

Reconnect the pump and power it on. Observe airflow and listen for unusual noises. Submerge the diffuser end (if applicable) and verify bubbles are consistent. Turn off the pump and watch for water rollback—there should be none. - Monitor for 24 Hours

Check periodically for leaks, loose fittings, or signs of stress. A well-installed valve should require no adjustment.

Common Mistakes and How to Avoid Them

Even experienced technicians occasionally make errors during installation. Here are frequent pitfalls and their solutions:

| Mistake | Consequence | Solution |

|---|---|---|

| Installing valve backward | Blocks airflow or fails to stop backflow | Double-check arrow direction before securing |

| Using mismatched tubing size | Leaks, disconnections under pressure | Measure inner diameter; use adapters if necessary |

| Placing valve too far from pump | Long tubing section remains vulnerable to backflow | Install within 6–12 inches of outlet |

| Ignoring environmental factors | UV degradation, freezing, or chemical exposure damages valve | Use protective housing in harsh conditions |

Real-World Example: Fixing a Flooded Aquarium Air Pump

David, a hobbyist with a 75-gallon freshwater tank, noticed his air pump was making a gurgling noise every time it cycled off. After two months, the pump began failing to restart consistently. Upon inspection, he found water inside the motor housing. The root cause? No check valve had been installed.

He replaced the damaged pump and added a 3/8” duckbill check valve within 8 inches of the outlet. After reassembly, the system ran silently, and no water returned to the pump after shutdown. Six months later, the pump continues to operate without issue—proving how a small $8 part can save costly replacements.

Frequently Asked Questions

Can I install multiple check valves?

Yes, but only if required by system design—such as long vertical runs or redundant safety measures. However, unnecessary valves increase resistance and may reduce airflow efficiency. One properly placed valve is usually sufficient.

How often should I inspect or replace the check valve?

Inspect every 3–6 months for debris, cracking, or stiffness. Rubber duckbill valves in aquariums typically last 1–2 years. In industrial settings, spring-loaded valves may last 3–5 years with maintenance.

Do all air pumps need a check valve?

While not all do, most benefit from one. Pumps operating below fluid level (e.g., basement sump aeration) absolutely require protection. Even above-water setups gain efficiency and longevity from proper backflow prevention.

Final Checklist Before Completion

- ✅ Power disconnected

- Ensure the pump is unplugged before starting.

- ✅ Correct valve selected

- Matches tubing size and application needs.

- ✅ Flow direction confirmed

- Arrow points from pump to outlet.

- ✅ Secure connections

- No wiggling or air leaks at joints.

- ✅ System tested under load

- Operates smoothly and prevents backflow when off.

Conclusion: Protect Your Investment

Installing a check valve on your air pump isn't just a technical detail—it's a fundamental step in safeguarding performance, efficiency, and equipment life. By taking less than 20 minutes to install and align the valve correctly, you prevent hours of troubleshooting, costly repairs, and unexpected downtime. Whether you're maintaining a peaceful home aquarium or a critical industrial system, this simple addition pays dividends in reliability and peace of mind.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?