Pendulum clocks are more than timekeeping devices—they’re heirlooms, works of art, and mechanical marvels that blend craftsmanship with precision. Over time, even the most well-maintained clock can fall out of sync or stop altogether. While professional restoration is an option, many common issues can be diagnosed and repaired at home with care, patience, and the right knowledge. This guide walks you through the essential steps to assess, clean, adjust, and restore your pendulum clock to full working order.

Understanding How Pendulum Clocks Work

Before attempting repairs, it’s crucial to understand the basic mechanics of a pendulum clock. These clocks operate on a system of gears, springs (or weights), an escapement mechanism, and the pendulum itself. The pendulum regulates time by swinging at a consistent rate, allowing the escapement to release the gear train in precise increments. Any disruption—whether from dirt, misalignment, or wear—can affect timekeeping or halt operation entirely.

The three main components involved in time regulation are:

- The Power Source: Either a wound spring or hanging weights that provide energy.

- The Gear Train: Transfers power from the source to the escapement.

- The Escapement and Pendulum: Controls the release of energy and maintains regular oscillation.

When a clock stops or runs inaccurately, the issue often lies in one of these systems—not necessarily the pendulum itself.

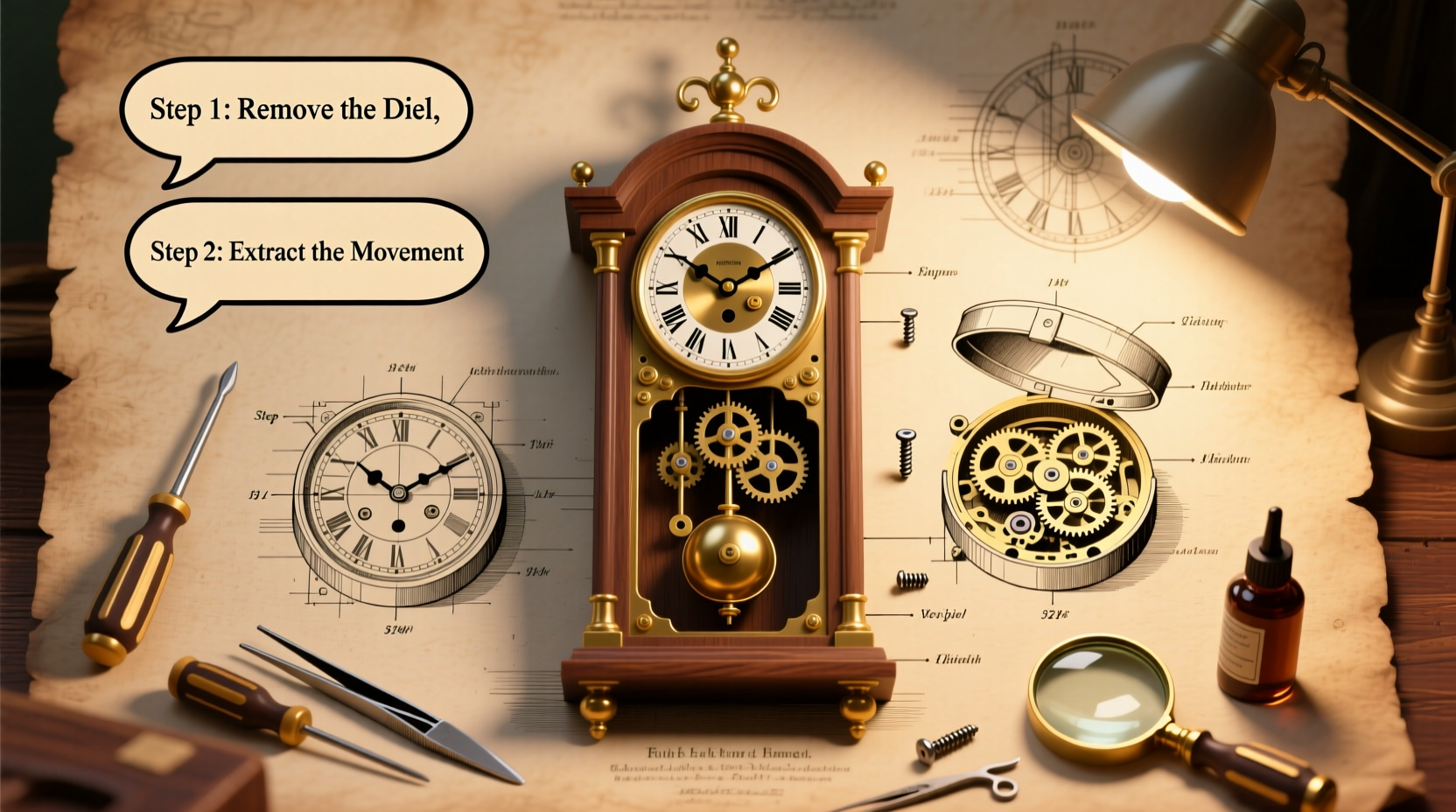

Step-by-Step Guide to Repairing Your Pendulum Clock

Follow this systematic approach to diagnose and repair common pendulum clock problems without needing professional help.

- Assess the Clock’s Condition

Begin by observing whether the clock runs at all. If it doesn’t start, check if the weights are properly hung (in weight-driven models) or if the spring is fully wound (in spring-driven models). Listen for any ticking—if there’s no sound, the escapement may be jammed. - Level the Clock

A slightly tilted clock will not run properly. Use a small bubble level across the top. Adjust the clock’s position on the wall or shelf until it is perfectly vertical in both directions. Even a slight lean can disrupt the pendulum’s swing. - Check the Pendulum Swing

Gently nudge the pendulum. It should swing smoothly and evenly. If it stops quickly or wobbles, the suspension spring (a thin metal strip holding the pendulum) may be bent or worn. Ensure the pendulum isn’t rubbing against the case or chime rods. - Clean the Movement (If Necessary)

Dust and old oil can gum up gears. Only disassemble the movement if you’re experienced or have access to proper tools. For light cleaning, use a soft brush and lint-free cloth to remove surface dust. Avoid water or solvents unless you plan a full overhaul. - Adjust the Beat

A clock “out of beat” produces an uneven tick-tock rhythm. The fix is subtle: tilt the clock slightly left or right until the ticking becomes even. Some clocks have an adjustment screw at the base of the pendulum. Turn it gently in small increments until the beat is balanced. - Regulate Timekeeping

Most pendulums have a nut at the bottom. Turning it up shortens the effective length, making the clock run faster. Turning it down slows it. Make adjustments in quarter-turn increments and wait 24 hours to observe changes.

Troubleshooting Common Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Clock won’t start | Not level, low power, or stuck escapement | Level the clock, rewind, or gently free the escapement with tweezers |

| Inconsistent ticking | Out of beat | Adjust beat via tilt or regulator screw |

| Runs fast/slow | Pendulum length incorrect | Turn rating nut up (faster) or down (slower) |

| Stops after winding | Power not transferring (gummed oil or worn gears) | Clean and lubricate or consult a specialist |

| Pendulum swings but hands don’t move | Slipping clutch or loose hand shaft | Secure hands or inspect motion works |

Essential Tools and Supplies

To perform basic repairs safely, gather these tools before beginning:

- Soft-bristle brush or compressed air (for dust removal)

- Lint-free cloths

- Small screwdrivers (jeweler’s set)

- Bubble level

- Clock-specific oil (e.g., synthetic clock oil—never use WD-40)

- Magnifying glass (for inspecting fine parts)

- Tweezers (non-magnetic, for handling small components)

Expert Insight: When to Call a Professional

While many issues can be resolved at home, some repairs require specialized skills. Clockmakers spend years mastering the intricacies of gear geometry, pivot polishing, and bushing replacement.

“Home maintenance keeps clocks running between services, but major wear or broken pivots need professional attention. Don’t force anything—if it resists, stop.” — Robert Langston, Master Horologist with 35 years of experience

Signs you should seek expert help include:

- Persistent oil leaks inside the movement

- Visible bent or broken gears

- No power transfer despite winding

- Chiming mechanism failure requiring disassembly

Mini Case Study: Restoring a 1920s Mantle Clock

A collector in Vermont inherited a Howard Miller mantle clock from her grandfather. It had been stored for over a decade and wouldn’t run past 10 minutes. She followed the home repair steps: first leveling the clock, then checking the pendulum swing. She noticed the tick was uneven—tick…tock……tick…tock—indicating it was out of beat.

After gently tilting the clock forward slightly, the beat normalized. She gave the movement a light dusting with a soft brush and rewound the spring. The clock ran for two days but lost 15 minutes. She adjusted the rating nut downward by half a turn. After another 24 hours, it was only 2 minutes slow. One more tiny adjustment brought it within 30 seconds per week—excellent for a vintage piece.

No disassembly or lubrication was needed. Simple observation and minor tweaks restored reliable function.

Preventative Maintenance Checklist

Keep your pendulum clock in top condition with this seasonal checklist:

- ✅ Level the clock every 3 months

- ✅ Wipe exterior with a dry, soft cloth monthly

- ✅ Check pendulum swing and beat quarterly

- ✅ Wind consistently (same day/time each week for spring models)

- ✅ Inspect for unusual noises or hesitation in ticking

- ✅ Schedule professional cleaning every 7–10 years

Frequently Asked Questions

Can I use household oil on my pendulum clock?

No. Standard oils like 3-in-1 or WD-40 are too thick or contain solvents that attract dust and degrade over time. Always use synthetic clock oil designed for precision movements.

Why does my clock run fast after I clean it?

Cleaning removes old, sticky oil, reducing friction temporarily. This can make the clock run faster until a proper lubrication is applied. If unregulated, readjust the pendulum length accordingly.

How often should I wind my pendulum clock?

Most eight-day clocks need winding weekly. 30-hour clocks require daily winding. Wind at the same time each cycle to maintain consistent power delivery.

Conclusion: Keep Time Alive at Home

Repairing a pendulum clock doesn’t require a workshop or decades of training—just attention to detail and respect for the mechanism. With the right approach, most common issues can be resolved quietly and effectively in your own home. By understanding how your clock works, performing regular checks, and knowing when to step back, you preserve not just timekeeping, but history and craftsmanship.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?