Plumbing leaks are among the most common household issues, often stemming from improperly sealed threaded pipe joints. One of the simplest and most effective solutions is the proper use of Teflon tape—also known as plumber’s tape or PTFE tape. When applied correctly, it creates a watertight seal that prevents drips, reduces corrosion, and extends the life of your plumbing system. Yet, despite its widespread availability, many DIYers and even some professionals apply it incorrectly, leading to leaks, stripped threads, or system contamination. This guide breaks down every step, tool, and technique needed to install Teflon tape properly for reliable, leak-proof connections.

Understanding Teflon Tape and How It Works

Teflon tape is made from polytetrafluoroethylene (PTFE), a synthetic fluoropolymer known for its chemical resistance, low friction, and excellent sealing properties. When wrapped around male pipe threads, it fills microscopic gaps between mating surfaces, creating a barrier against water, gas, or air leakage. Unlike liquid thread sealants, Teflon tape doesn’t cure or harden, allowing for future disassembly without damaging fittings.

It’s important to note that not all Teflon tapes are the same. Different colors indicate specific uses:

| Tape Color | Recommended Use | Not Suitable For |

|---|---|---|

| White (Standard) | Water pipes (potable and non-potable) | Gas lines, high-pressure steam |

| Yellow (Gas-rated) | Natural gas, propane, butane lines | Water systems |

| Pink (Plumbing) | General residential plumbing | Industrial applications |

| Green (Non-petroleum) | Oxygen lines, medical gas systems | Oil-based environments |

“Using the wrong type of Teflon tape can compromise safety, especially in gas or oxygen systems. Always match the tape color to the application.” — James Rutherford, Master Plumber & HVAC Specialist

Step-by-Step Guide to Installing Teflon Tape

Proper installation is critical. Follow these steps precisely to ensure a secure, long-lasting seal:

- Clean the Threads Thoroughly: Use a clean rag or wire brush to remove dirt, old tape residue, rust, or grease from the male threads. Any debris can prevent a tight seal.

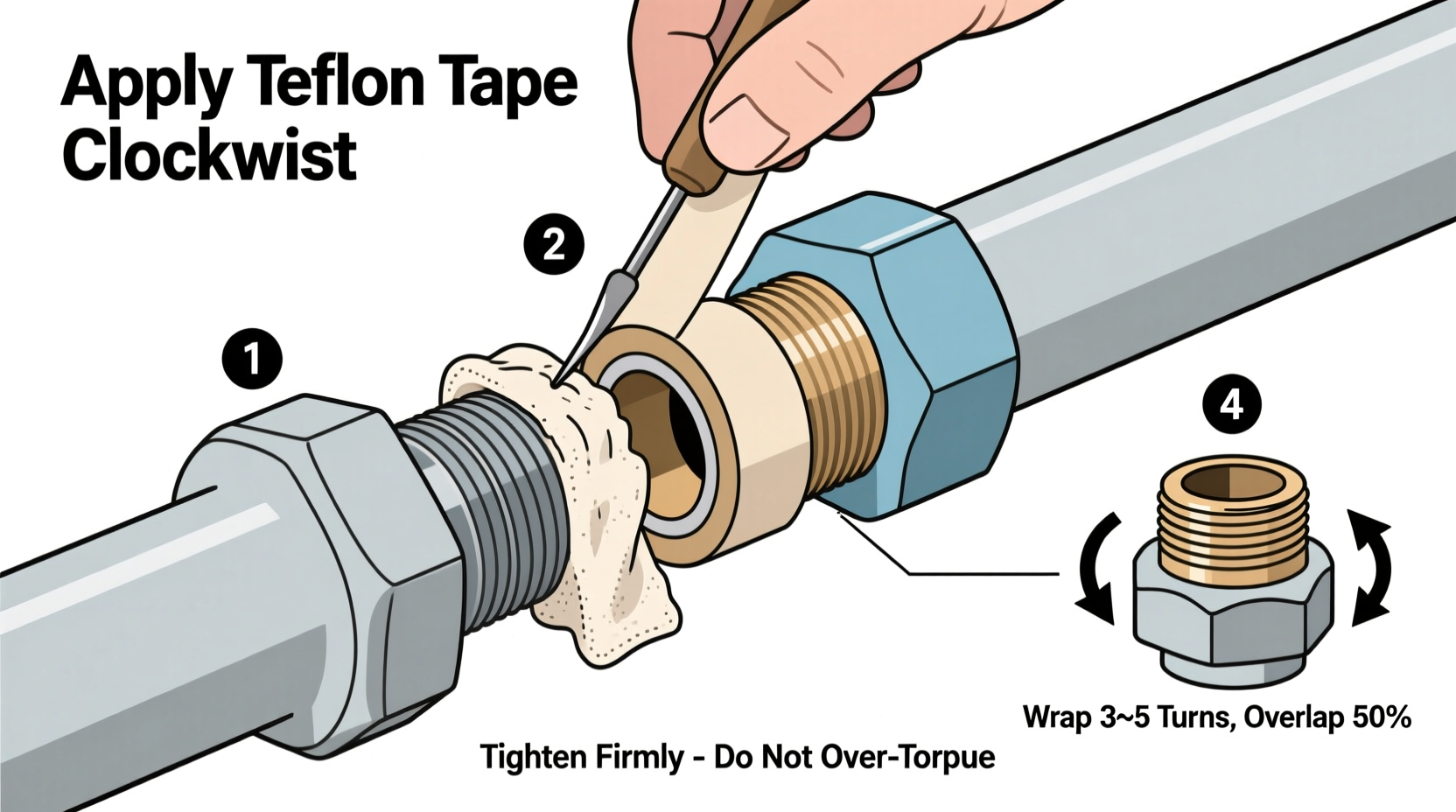

- Determine Wrap Direction: Hold the fitting so you’re looking at the end of the male threads. Wrap the tape clockwise—the same direction you’ll turn the fitting when tightening. This ensures the tape doesn’t unravel during installation.

- Start Behind the Threads: Begin wrapping about one thread back from the edge. This prevents tape ends from peeling into the pipe interior, where they could break off and clog valves or aerators.

- Apply Even Tension: Pull the tape taut as you wrap, avoiding wrinkles or bunching. Overlap each layer by about half the tape width for consistent coverage.

- Wrap 3–5 Times: For standard ½” to ¾” residential pipes, three to five full wraps are sufficient. Larger diameters may require more; undersized wraps risk leaks, while excessive layers can make threading difficult and damage fittings.

- Press Tape Into Threads: After wrapping, use your thumb to press the tape firmly into the grooves. This improves adhesion and ensures full contact.

- Assemble Immediately: Install the fitting right after applying tape. Delayed assembly can allow dust or moisture to compromise the seal.

- Tighten Properly: Hand-tighten first, then use a wrench for an additional 1–2 turns. Over-tightening can strip threads or squeeze out the tape, causing leaks.

Common Mistakes and How to Avoid Them

Even experienced handymen make errors with Teflon tape. Recognizing these pitfalls can save time, materials, and prevent water damage.

- Wrapping in the Wrong Direction: Counter-clockwise wrapping causes the tape to peel off as the fitting is screwed in, leaving bare threads exposed.

- Over-Wrapping: More tape isn’t better. Excess tape increases torque resistance and can deform threads or create gaps instead of sealing them.

- Starting on the Edge: Beginning directly on the first thread risks sending loose fragments into the system, potentially clogging filters or valves.

- Using Water Tape on Gas Lines: Standard white tape isn’t rated for gas. Always use yellow gas-rated tape for fuel lines to meet safety codes.

- Skipping Thread Cleaning: Old tape or corrosion prevents proper seating. Clean threads are essential for a reliable seal.

Real-World Example: A Kitchen Faucet Leak Solved

A homeowner in Portland reported a persistent drip beneath their kitchen sink after replacing the faucet supply lines. The connections seemed tight, yet water seeped from the shutoff valve threads. Upon inspection, a plumber found remnants of old Teflon tape still clinging to the male threads, with new tape haphazardly layered on top. The tape had been wrapped counter-clockwise, causing it to unravel during tightening. The solution was simple: clean the threads completely, reapply fresh white Teflon tape clockwise with four even wraps, and hand-tighten followed by a quarter-turn with a wrench. The leak stopped immediately, demonstrating how minor oversights can lead to major issues—and how proper technique delivers instant results.

Checklist: Perfect Teflon Tape Application

Use this checklist before every application to ensure success:

- ✅ Choose the correct tape color for the application (white for water, yellow for gas)

- ✅ Clean male threads with a dry cloth or brush

- ✅ Hold fitting so threads face you—wrap tape clockwise

- ✅ Start one thread behind the edge

- ✅ Apply 3–5 smooth, overlapping wraps with firm tension

- ✅ Press tape into threads with your thumb

- ✅ Screw on fitting by hand first, then use a wrench for 1–2 additional turns

- ✅ Test the connection slowly under pressure and check for leaks

Frequently Asked Questions

Can I reuse Teflon tape after disconnecting a fitting?

No. Once a taped joint is unscrewed, the tape is stretched, torn, or displaced. Always remove old tape and reapply fresh tape before reconnecting.

Is Teflon tape necessary if I’m using pipe dope?

Generally, no. Pipe dope (thread sealant) and Teflon tape serve the same purpose. Using both can lead to over-lubrication and improper seating. Choose one method unless specified otherwise by the manufacturer.

Why is my connection still leaking after using Teflon tape?

Possible reasons include incorrect wrap direction, insufficient wraps, dirty threads, over-tightening, or using degraded tape. Double-check each step and consider switching to a thicker tape or pipe dope for large or high-pressure fittings.

Final Tips for Long-Term Success

Store Teflon tape in a cool, dry place away from sunlight, which can degrade the PTFE over time. Keep different colors clearly labeled to avoid accidental misuse. For infrequently used tools, inspect tape rolls periodically for brittleness or stickiness.

Take Action Today

A properly sealed pipe joint should last for years without maintenance. By mastering the correct use of Teflon tape, you eliminate a common source of household water waste and prevent costly water damage. Whether you're fixing a dripping showerhead or installing a new washing machine line, take a few extra minutes to apply the tape right. Your plumbing—and your peace of mind—will thank you.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?