Fluorescent lighting has long been a staple in offices, garages, and commercial buildings due to its efficiency over incandescent bulbs. However, LED technology now offers superior performance, longer lifespan, and greater energy savings. Converting existing fluorescent fixtures to LED is a smart upgrade—but it must be done correctly to ensure safety, compliance, and optimal results. This guide walks you through every phase of the conversion process with practical advice, technical clarity, and real-world insights.

Why Upgrade from Fluorescent to LED?

Fluorescent tubes typically last 10,000 to 15,000 hours and consume significantly more energy than LEDs. In contrast, modern LED tubes can last up to 50,000 hours and use up to 50% less electricity for the same light output. The benefits go beyond cost savings:

- Lower energy bills: LEDs convert more electricity into light and less into heat.

- Reduced maintenance: Fewer replacements mean lower labor and material costs.

- Better light quality: LEDs offer higher color rendering index (CRI) and instant full brightness without flickering.

- Environmental impact: No mercury content, unlike fluorescent tubes, making disposal safer and easier.

“Switching to LED in commercial settings isn’t just an upgrade—it’s a long-term operational advantage.” — James Lin, Electrical Systems Consultant

Understanding Your Current Fixture: Types of Fluorescent Ballasts

Before any conversion, identify your fixture’s ballast type. The ballast regulates electrical current to the tube. There are two main types:

| Type | How It Works | Compatibility with LED |

|---|---|---|

| Magnetic (T12) | Older, bulkier, less efficient | Poor; usually requires bypass or replacement |

| Electronic (T8/T5) | Newer, quieter, more efficient | May support plug-and-play LED tubes |

If your fixture uses T12 tubes, it likely has a magnetic ballast and should be rewired for direct-wire LED tubes. T8 fixtures with electronic ballasts may allow plug-and-play upgrades, but longevity improves when ballasts are removed entirely.

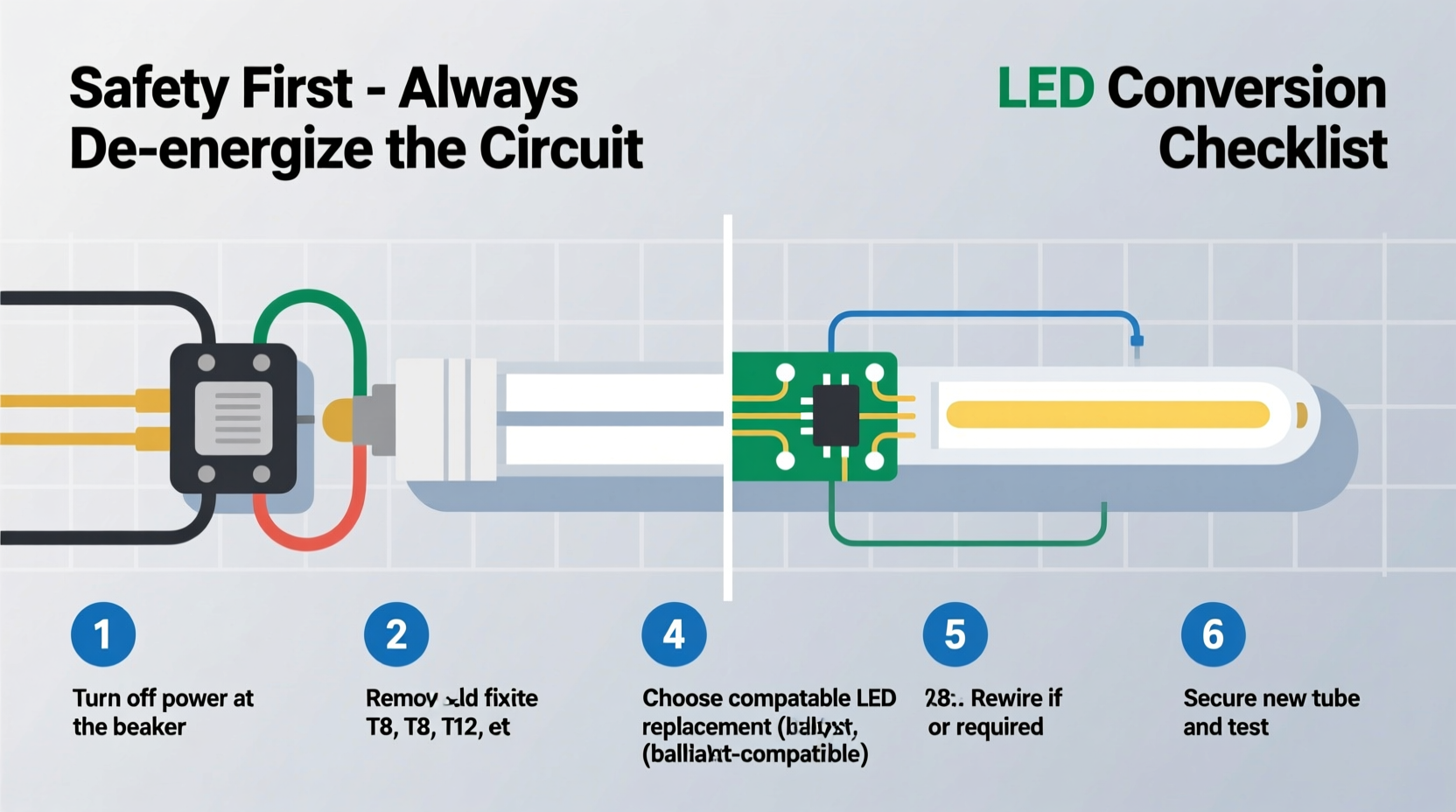

Step-by-Step Conversion Process

Safely upgrading fluorescent tubes to LED involves several critical steps. Follow this timeline to avoid electrical hazards and ensure reliable operation.

- Turn off power at the breaker: Never assume switching off the wall switch is enough. Confirm power is off using a non-contact voltage tester.

- Remove the old fluorescent tube: Rotate the tube 90 degrees and gently slide it out of the tombstone sockets.

- Inspect the ballast: Check the label on the ballast to determine compatibility. If it’s outdated or failing, plan for ballast bypass.

- Choose your LED retrofit method: Decide between plug-and-play, ballast bypass, or hybrid LED tubes based on your fixture and goals.

- Modify wiring if bypassing ballast: Disconnect wires from the ballast and rewire tombstones to send line voltage directly to the tube ends. Follow manufacturer diagrams precisely.

- Install new LED tubes: Insert according to end-cap configuration (single-end or double-end powered). Ensure secure seating.

- Restore power and test: Turn the breaker back on and verify even illumination without flickering.

Choosing the Right LED Tube Type

There are three primary options for retrofitting:

- Plug-and-play (Type A): Works with existing ballast. Easy install but depends on ballast life.

- Ballast bypass / Direct wire (Type B): Requires removing the ballast and rewiring. Most efficient and reliable.

- Hybrid (Type A/B): Can operate with or without a ballast. Offers flexibility during transition.

For long-term reliability, Type B (direct-wire) is recommended. While installation takes more time, eliminating the ballast removes a common point of failure and reduces energy loss.

Common Pitfalls and How to Avoid Them

Even experienced DIYers make mistakes when converting lighting. These do’s and don’ts will help you stay safe and effective.

| Do’s | Don’ts |

|---|---|

| Always shut off power at the circuit breaker | Never work on live circuits |

| Follow the LED manufacturer’s wiring diagram | Don’t assume all tombstones are wired the same |

| Use wire nuts rated for the conductor size | Don’t leave exposed copper or loose connections |

| Label bypassed fixtures to prevent future confusion | Don’t reuse damaged or corroded sockets |

Real-World Example: Warehouse Lighting Retrofit

A mid-sized warehouse in Ohio operated 120 fluorescent T12 fixtures, each consuming 75 watts (including ballast loss). With lights running 14 hours daily, annual energy costs exceeded $14,000.

The facility manager opted for a Type B (ballast bypass) LED conversion using 40-watt equivalent LED tubes. Each fixture was rewired by a licensed electrician over a weekend shutdown. The project cost $8,200 in materials and labor.

Post-upgrade, energy consumption dropped by 53%. Annual savings reached $7,500, with a payback period of just 13 months. Additionally, maintenance calls for flickering or dead tubes ceased entirely.

Checklist: Safe Fluorescent-to-LED Conversion

Use this checklist before, during, and after your conversion project:

- ☑ Shut off power at the breaker and verify with a voltage tester

- ☑ Identify tube type (T8, T12) and ballast compatibility

- ☑ Choose appropriate LED tube (Type A, B, or A/B)

- ☑ Gather tools: screwdriver, wire stripper, voltage tester, wire nuts

- ☑ Remove fluorescent tube carefully

- ☑ Disconnect and remove ballast (for Type B installs)

- ☑ Rewire tombstones per manufacturer instructions

- ☑ Install new LED tube securely

- ☑ Restore power and test operation

- ☑ Label modified fixtures for future reference

Frequently Asked Questions

Can I mix LED and fluorescent tubes in the same fixture?

No. Mixing tube types can cause uneven lighting, ballast stress, and potential safety issues. Always convert entire fixtures at once.

Are LED retrofits code-compliant?

Yes, provided the installation follows NEC (National Electrical Code) standards and the LED product is UL-listed. Bypassing the ballast is allowed as long as the fixture remains labeled and safe.

Do I need an electrician to convert fluorescent to LED?

While DIY is possible for those with electrical experience, hiring a licensed electrician ensures compliance, safety, and warranty validity—especially for large-scale or commercial projects.

Final Thoughts and Next Steps

Converting fluorescent tubes to LED is one of the most cost-effective energy upgrades available today. When done safely and correctly, it delivers immediate reductions in energy use, maintenance demands, and environmental impact. Whether you're upgrading a single garage fixture or an entire office building, the principles remain the same: prioritize safety, understand your system, and choose quality components.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?