Removing a watch back is a routine task for collectors, repairers, and enthusiasts—but doing it incorrectly can lead to scratches, stripped screws, or compromised water resistance. Whether you're replacing a battery, servicing the movement, or simply inspecting the interior, understanding the correct method for your specific watch type is essential. This guide covers every major watch back design, the right tools to use, and proven techniques to prevent damage.

Understanding Watch Back Types

Watches come with several different case back designs, each requiring a unique approach. The three primary types are snap-on, screw-down, and caseback with screws. Identifying your watch’s back type is the first step in safe removal.

- Snap-on backs: Held in place by tension and friction. Common in vintage and budget watches.

- Screw-down backs: Threaded onto the case and tightened like a lid. Often found on dive and sports watches.

- Caseback with screws: Uses small screws around the perimeter to secure the back. Typical in high-end mechanical watches.

Misidentifying the type can result in using the wrong tool or excessive force. For example, attempting to pry off a screw-down back can damage the threads and render the watch no longer waterproof.

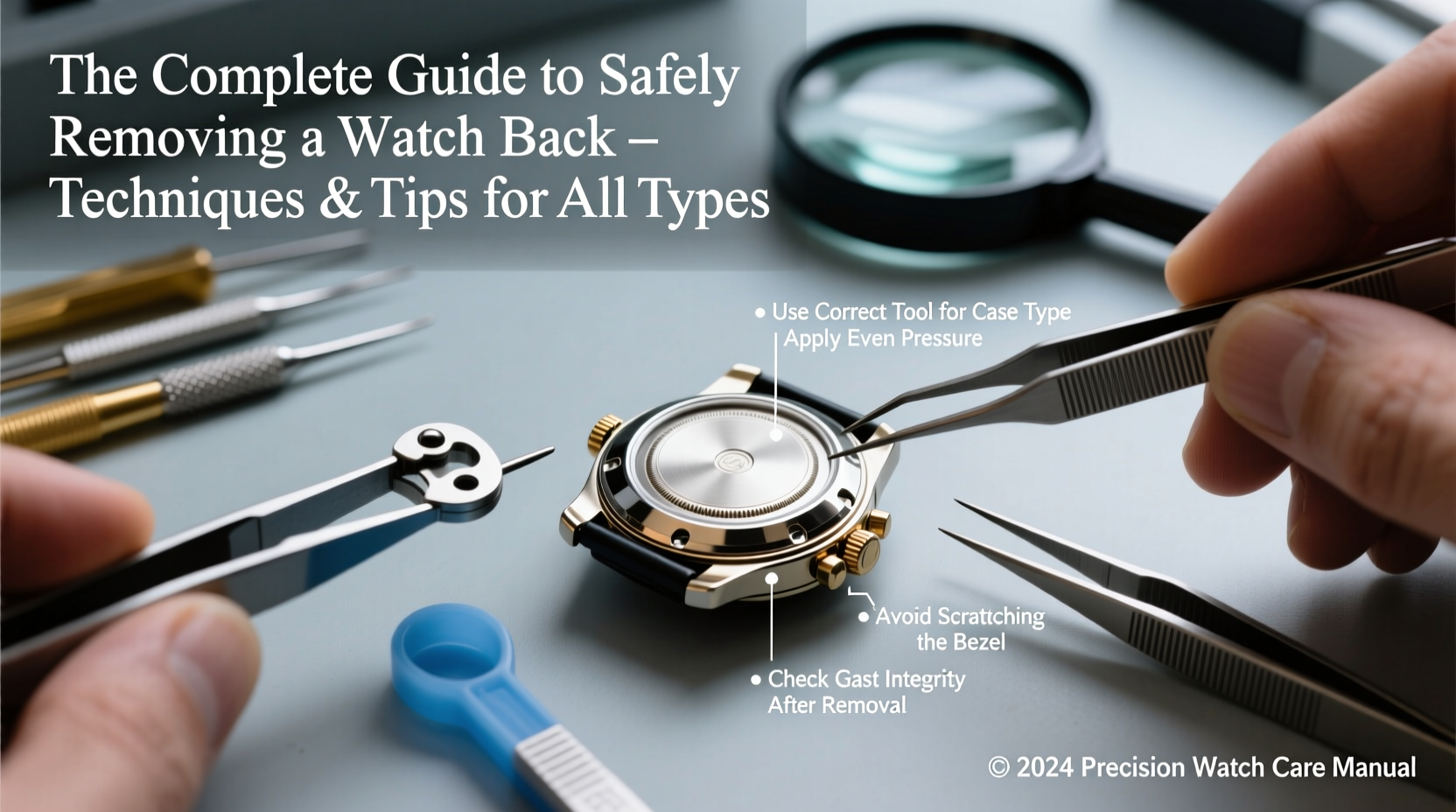

Essential Tools for Safe Removal

Using improper tools like knives or pliers risks damaging both the watch and your fingers. Invest in purpose-built instruments designed for precision work.

| Tool | Use Case | Notes |

|---|---|---|

| Screw-back wrench (pin spanner) | Screw-down backs with notches | Available in multiple sizes; match pins to notches precisely |

| Case knife or pry tool | Snap-on backs | Thin blade slides between case and back without scratching |

| Watch case holder | Holds case steady during removal | Prevents slippage and protects bezel |

| Jaxa wrench | Backs with radial notches | Adjustable pins fit various diameters |

| Precision screwdriver set | Screw-secured backs | Use correct size to avoid cam-out and damaged heads |

A quality toolkit pays for itself in avoided repairs. Never substitute with improvised tools unless absolutely necessary—and even then, proceed with extreme caution.

Step-by-Step Guide to Removing Each Type

Removing a Snap-On Back

- Place the watch securely in a case holder, dial side down.

- Align the tip of a case knife into the notch or gap along the case edge.

- Gently twist the handle upward to create leverage. Do not force.

- Work around the perimeter, lifting slightly at different points until the back releases.

- Remove the back carefully and set aside on a soft surface.

Removing a Screw-Down Back

- Determine the direction of the thread—most are reverse-threaded (turn counterclockwise to tighten).

- Select a pin spanner or Jaxa wrench that fits snugly into the notches.

- Apply firm, even pressure and turn in the correct direction to loosen.

- If resistant, use two hands or a padded vise to stabilize the case.

- Once loose, unscrew completely by hand to avoid dropping the tool inside.

Removing a Screw-Secured Back

- Inspect the screws around the back’s perimeter—usually 4 to 6 in number.

- Use a precision screwdriver matching the screw head (Phillips, flat, or specialty).

- Loosen each screw gradually, turning a quarter-turn per screw to maintain even pressure.

- Remove screws one at a time and place them on a magnetic mat or tray.

- Lift the back straight off to avoid snagging internal components.

“Even slight misalignment when tightening screw-down backs can compromise water resistance. Always verify torque and alignment.” — Daniel Reyes, Master Watchmaker, Swiss Time Institute

Avoiding Common Mistakes

Many watch owners inadvertently damage their timepieces due to simple oversights. Awareness of these pitfalls can save hundreds in repair costs.

- Using excessive force: Watches are precision instruments. If a back doesn’t budge, reassess the method before applying more pressure.

- Ignoring thread direction: Some screw-down backs tighten counterclockwise—a reversal designed to prevent accidental loosening.

- Mixing up screws: On multi-screw backs, screws may vary slightly in length. Keep them organized.

- Skipping cleaning: Dust or debris in the gasket groove can prevent proper resealing.

- Not checking for seals: O-rings degrade over time. Inspect and replace if cracked or flattened.

Mini Case Study: Reviving a Vintage Seiko

A collector acquired a 1970s Seiko 5 with a stuck snap-on back. Attempting to open it with a butter knife left deep gouges around the rim. After sourcing a proper case knife and placing the watch in a padded holder, he warmed the case in his palms for two minutes. Using controlled leverage at multiple points, the back released cleanly. Inside, he discovered a degraded gasket and replaced it before reassembly. The lesson? Patience and the right tools preserve both function and value.

Checklist: Preparing to Open Your Watch Back

- ✔ Identify the case back type (snap, screw, or screw-secured)

- ✔ Gather appropriate tools (no improvisation)

- ✔ Work in a clean, well-lit area with minimal distractions

- ✔ Use a case holder to secure the watch

- ✔ Have a soft tray or magnetic mat for screws and small parts

- ✔ Inspect the gasket and sealing surfaces before reassembly

- ✔ Document the process with notes or photos if needed

Frequently Asked Questions

Can I remove a watch back without special tools?

It’s not recommended. While some backs can be opened with improvised methods, the risk of cosmetic or functional damage is high. Proper tools are affordable and widely available online or from watch supply stores.

How often should I check or replace the case back gasket?

For watches rated for water resistance, inspect the gasket every 1–2 years. Replace it if it shows signs of cracking, flattening, or loss of elasticity. Even watches not used in water benefit from gasket maintenance to prevent dust and moisture ingress.

My screw-down back won’t tighten fully. What should I do?

Do not force it. Check for debris in the threads or a misaligned gasket. Clean both the case and back threads with a dry brush. If the issue persists, consult a professional—cross-threading can ruin the case.

Final Tips for Long-Term Care

Opening a watch back is just one part of responsible ownership. After servicing, ensure the back is properly seated and tightened. For screw-down types, verify full engagement by checking alignment marks (if present). Store tools clean and dry to prevent corrosion. And remember: if you’re ever uncertain, especially with valuable or antique pieces, seek help from a certified watchmaker.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?