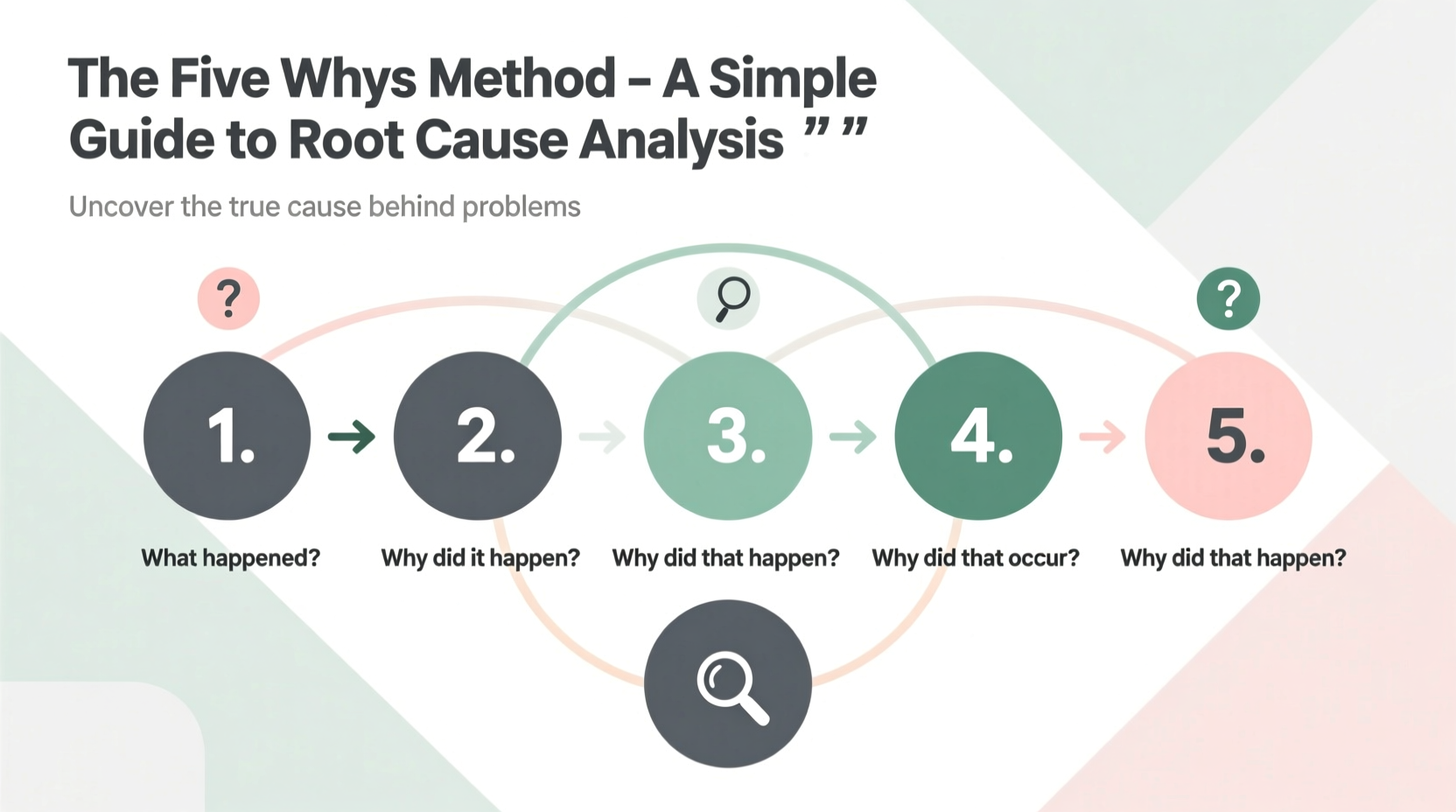

When problems arise in organizations—whether it's a production delay, a software bug, or a customer service failure—the immediate reaction is often to fix the symptom. But without addressing the underlying cause, the same issue will likely resurface. The Five Whys method offers a straightforward yet powerful way to dig beneath surface-level symptoms and uncover the true root of a problem. Developed within the Toyota Production System, this technique has since been adopted across industries as a cornerstone of effective problem-solving.

The beauty of the Five Whys lies in its simplicity. It requires no advanced statistical tools or complex diagrams—just disciplined questioning. By repeatedly asking \"why?\" at least five times, teams can peel back layers of causality and reach actionable insights that lead to lasting improvements.

Understanding the Origins and Purpose of the Five Whys

The Five Whys method was pioneered by Sakichi Toyoda, the founder of Toyota Industries, and later refined by Taiichi Ohno, the architect of the Toyota Production System. Ohno described the method using a real example: a machine had stopped working. Instead of simply restarting it, the team asked why. The answer led to another question, and so on, until they discovered a missing filter was allowing metal shavings into the machinery—a fundamental design flaw.

“Ask 'why' five times about every matter.” — Taiichi Ohno, Toyota Production System pioneer

This iterative approach prevents premature conclusions and encourages deeper thinking. It shifts focus from assigning blame to understanding systems. In Ohno’s view, every problem is an opportunity to improve processes, not punish individuals.

Today, the Five Whys is used in lean manufacturing, healthcare, IT operations, product development, and even personal decision-making. Its universal applicability stems from its core principle: sustainable solutions come from understanding causes, not just treating effects.

How the Five Whys Works: A Step-by-Step Process

Applying the Five Whys doesn’t require special training, but it does require discipline and objectivity. Follow these steps to conduct an effective root cause analysis:

- Define the problem clearly. Start with a specific, observable issue. Avoid vague statements like “poor performance” and instead use precise descriptions such as “server outage lasted 45 minutes at 3 PM.”

- Ask 'Why?' for the first time. Identify the direct cause of the problem. Make sure the answer is fact-based, not speculative.

- Continue asking 'Why?' up to five times. Each answer becomes the basis for the next question. Stop when you reach a process, policy, or systemic issue that can be changed.

- Verify the root cause. Ensure each link in the chain is supported by evidence. Avoid assumptions or jumping to conclusions.

- Develop and implement corrective actions. Focus on fixing the root cause, not just the initial symptom.

Real-World Example: Solving a Recurring Website Downtime Issue

A mid-sized e-commerce company experienced repeated website crashes during peak traffic hours. The technical team initially blamed server capacity. After restoring service multiple times, they decided to apply the Five Whys to prevent recurrence.

- Problem: Website crashed during Black Friday sales.

- Why 1: Why did the website crash? → The server reached maximum load and shut down.

- Why 2: Why did the server reach maximum load? → Traffic exceeded expected volume by 300%.

- Why 3: Why wasn’t the system scaled for higher traffic? → Auto-scaling was disabled during a recent update.

- Why 4: Why was auto-scaling disabled? → A developer turned it off to test a new feature but forgot to re-enable it.

- Why 5: Why was there no process to verify critical settings after testing? → The team lacked a deployment checklist for production changes.

The root cause was not insufficient infrastructure, but a missing operational procedure. The solution? Implement a mandatory pre-deployment checklist and peer review for all production changes. This simple procedural fix prevented future outages and improved overall release reliability.

Do’s and Don’ts When Applying the Five Whys

To get the most out of the Five Whys, avoid common pitfalls. The following table outlines key behaviors to embrace and those to avoid:

| Do’s | Don’ts |

|---|---|

| Base answers on data and observation | Rely on assumptions or opinions |

| Involve cross-functional team members | Let one person dominate the discussion |

| Stop when you reach a systemic cause (e.g., process, training, design) | Blame individuals or stop at the first plausible reason |

| Document the full chain of reasoning | Conduct the analysis verbally with no follow-up |

| Test your root cause with a small pilot change | Implement broad changes without validation |

When the Five Whys Falls Short: Limitations and Alternatives

While effective in many cases, the Five Whys isn’t a one-size-fits-all solution. It works best for problems with a single, linear cause. For complex issues involving multiple contributing factors—such as safety incidents or system failures with human, technical, and environmental components—it may oversimplify reality.

In such cases, more structured methods like Fishbone (Ishikawa) diagrams, Failure Mode and Effects Analysis (FMEA), or Root Cause Analysis (RCA) software tools provide better frameworks. Additionally, the Five Whys can lead to inconsistent results if different teams interpret causes differently. To mitigate this, combine it with data analysis and validation techniques.

Another limitation is cognitive bias. Teams may unconsciously steer questions toward familiar answers or avoid uncomfortable truths. To counteract this, appoint a neutral facilitator and encourage dissenting viewpoints during the session.

Practical Checklist for Conducting a Five Whys Session

Use this checklist before, during, and after your next Five Whys analysis to ensure thoroughness and impact:

- ✅ Clearly define the problem with measurable details (when, where, how often)

- ✅ Gather a diverse team familiar with the process

- ✅ Start with the first 'Why' based on observed facts

- ✅ Challenge each answer—ask, “Is this the real reason, or just a symptom?”

- ✅ Stop at a root cause that points to a changeable process or system

- ✅ Document the entire chain of reasoning and share it with stakeholders

- ✅ Propose at least one corrective action targeting the root cause

- ✅ Follow up in 2–4 weeks to assess whether the fix worked

Frequently Asked Questions

Do you always need to ask 'why' exactly five times?

No. The number five is a guideline, not a rule. Some problems may reveal their root cause in three whys; others may take seven or more. The goal is to keep asking until you reach a systemic issue that can be addressed through improvement.

Can the Five Whys be used for personal problem-solving?

Absolutely. The method works well for individual reflection. For example, if you're consistently late to work, asking 'why' repeatedly might lead from traffic delays to poor morning routines to lack of preparation the night before—revealing a habit-based root cause you can change.

What if we identify multiple root causes?

If multiple independent causes emerge, consider running separate Five Whys chains for each. Alternatively, switch to a multi-cause analysis tool like a fishbone diagram to map all contributing factors systematically.

Conclusion: Turn Problems into Progress

The Five Whys method proves that the most powerful tools are often the simplest. By fostering curiosity and discipline, it transforms reactive firefighting into proactive improvement. Whether you're troubleshooting a malfunctioning machine, improving customer satisfaction, or refining a software release process, asking 'why' with intention can uncover insights that drive meaningful change.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?