Whether you're preparing a shipment, organizing warehouse inventory, designing custom packaging, or moving homes, knowing how to determine accurate box dimensions is essential. A small miscalculation can lead to overpaying for shipping, damaged goods, inefficient storage, or rejected deliveries. Yet surprisingly, many individuals and businesses still estimate rather than measure—costing time, money, and reliability. This guide breaks down the precise methods, tools, and principles behind measuring boxes correctly for any application.

Why Accurate Box Dimensions Matter

Precise measurements are not just about numbers—they impact real-world outcomes. Carriers like FedEx, UPS, and DHL use dimensional weight (dim weight) pricing, which combines physical size and density to calculate shipping costs. A box that’s even one inch too wide can jump into a higher pricing tier. In warehousing, incorrect assumptions about box size lead to poor space utilization, wasted racks, and logistical bottlenecks.

For product designers and e-commerce sellers, inaccurate box specs result in excess material usage, higher packaging costs, and customer dissatisfaction due to oversized or flimsy containers. The ripple effect of a poorly measured box extends far beyond the tape measure.

“Dimensional accuracy isn’t optional in modern logistics—it’s foundational. One millimeter off today can mean thousands in losses tomorrow.” — Rafael Mendez, Senior Logistics Engineer at SupplyChain360

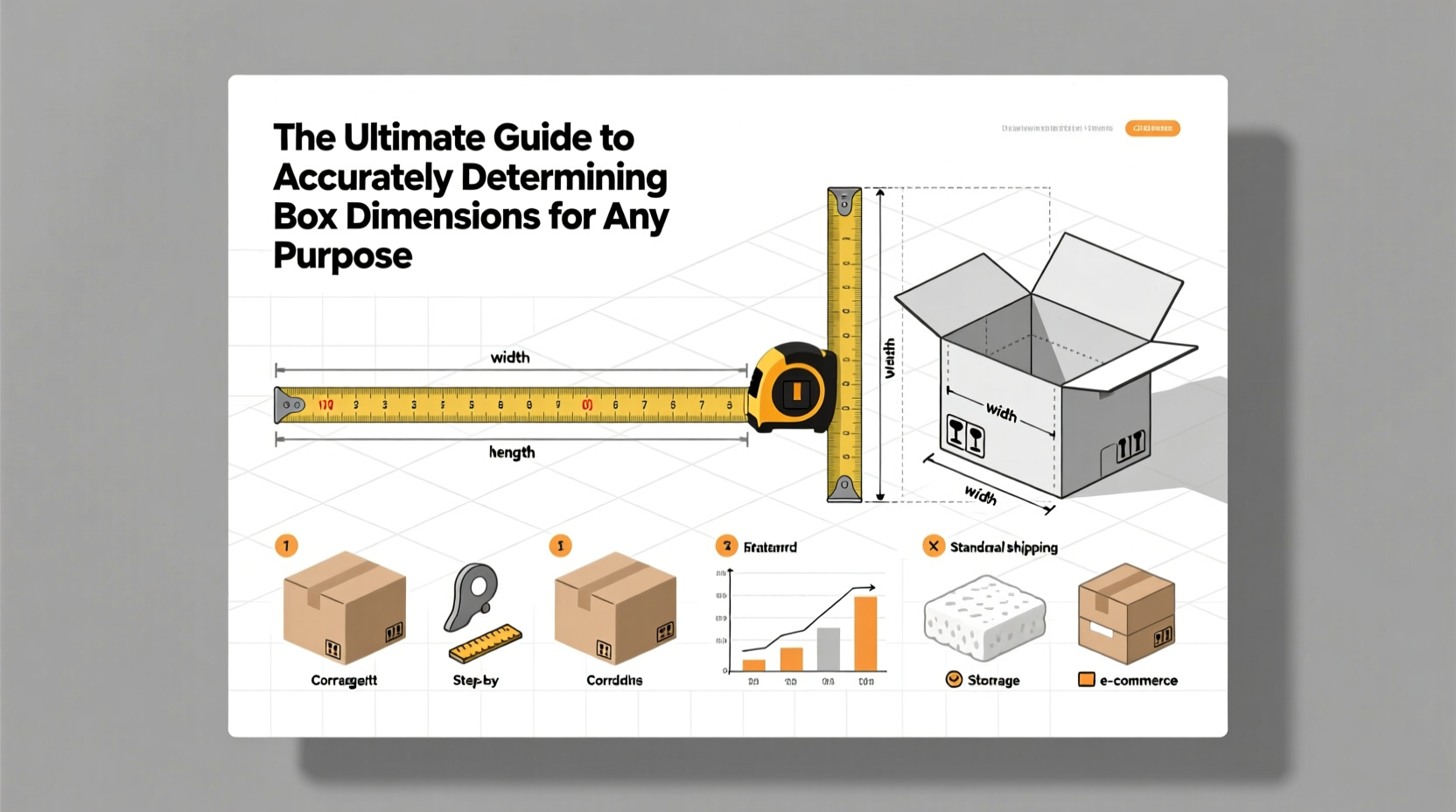

Step-by-Step: How to Measure a Box Correctly

Measuring a box may seem straightforward, but consistency in method ensures reliability. Follow this sequence every time:

- Prepare the box: Ensure it’s fully assembled, closed, and sitting on a flat surface. Do not measure a partially folded or open box.

- Identify orientation: Position the box so the opening faces you. This establishes the standard order: length, width, then height.

- Measure length: Use a rigid tape measure from left to right across the longest side of the top flap. This is typically the longest dimension.

- Measure width: Go from front to back across the shorter side of the top flap. This is usually the second-longest dimension.

- Measure height: Measure vertically from the bottom to the top of the box, perpendicular to the floor.

- Record in order: Always list as Length × Width × Height (e.g., 18\" × 12\" × 10\").

- Double-check: Re-measure each side to confirm consistency, especially if using manual tools.

Common Measurement Mistakes (and How to Avoid Them)

Even experienced packers make these errors. Recognizing them helps prevent costly oversights:

- Mixing up length and width: Always define length as the longest horizontal dimension on the top panel when the box is open toward you.

- Measuring outside vs. inside: For shipping and external fit, use outside dimensions. For internal capacity or product fit, measure inside walls, subtracting material thickness.

- Ignoring bulge or deformation: Overfilled or warped boxes expand. If the box sags or bows, measure at its widest point—but consider resizing.

- Using inconsistent units: Never mix inches and centimeters. Confirm whether your system uses imperial or metric before recording.

- Estimating instead of measuring: “Looks like 12x12” is not enough. Visual guesses often understate actual size by 5–10%.

| Mistake | Consequence | Solution |

|---|---|---|

| Incorrect order (W×L×H instead of L×W×H) | Data confusion in inventory systems | Adopt a universal labeling standard |

| Measuring only one side and assuming symmetry | Asymmetrical boxes cause stacking issues | Measure all sides independently |

| Not accounting for pallet base or lid overhang | Fits issues in containers or shelves | Include full footprint including protrusions |

Choosing the Right Tools for Precision

The tool you use affects accuracy. While a basic tape measure works for occasional use, high-volume operations benefit from advanced options:

- Tape Measure: Ideal for one-off measurements. Choose a locking, retractable steel model with clear markings.

- Digital Calipers: Useful for small boxes or verifying material thickness, especially corrugated board gauge.

- Dimensioning Systems: Automated sensors and cameras used in warehouses that capture length, width, height, and weight simultaneously. These integrate with WMS (Warehouse Management Systems).

- Laser Distance Measures: Efficient for large crates or palletized loads where reach matters.

Real-World Example: E-Commerce Fulfillment Error

A mid-sized online retailer selling kitchenware shipped most orders in uniform 14×10×8-inch boxes. When introducing a new line of large cutting boards, they assumed the existing box would suffice. However, the boards required slight diagonal placement, causing the box to bulge to 14.5×10.3×8.2 inches. Unnoticed, this pushed the dim weight into a higher bracket. Over three months, dimensional surcharges cost the company $7,200 in unexpected fees. After auditing their packaging process, they introduced a pre-shipment verification step using a digital dimensioner, reducing errors by 98% and saving over $5,000 monthly.

When Internal vs. External Dimensions Matter

Understanding the difference between internal and external dimensions is critical depending on your goal:

- External dimensions: Used for shipping, storage layout, rack compatibility, and freight calculations. Always include any ridges, handles, or sealed seams.

- Internal dimensions: Crucial when fitting products snugly. Measure from inner wall to inner wall. Subtract twice the board thickness (typically 1/8\" to 1/4\" for standard corrugated).

For example, a box labeled externally as 12×12×12 inches might have an internal clearance of only 11.75×11.75×11.75 inches—enough to block insertion of a 12-inch cube.

Checklist: Verify Your Box Measurements Like a Pro

Use this checklist before finalizing any box specification or shipment:

- ☐ Box is fully assembled and closed

- ☐ Measured from outside edges unless internal fit is the goal

- ☐ Length is the longest horizontal top dimension

- ☐ All three dimensions recorded in L×W×H order

- ☐ Units are consistent (all inches or all cm)

- ☐ Double-checked with a second measurement

- ☐ Rounded up appropriately (carriers often round up to nearest inch)

- ☐ Documented and saved for future reference

FAQ

Do carriers measure boxes themselves?

Yes, major carriers use automated dimensioning systems at sorting hubs. If their scan differs from your declared size, they will bill based on their measurement. Always measure as accurately as they would.

How do I measure an irregularly shaped item in a box?

Place the item securely inside, close the box, then measure the outermost points of the box itself—even if it’s slightly deformed. For pricing, the box defines the footprint, not the object within.

Should I include tape or labels in the measurement?

No, standard tape and labels don’t add meaningful volume. However, bulky reinforcements, corner boards, or strapping may increase effective size—measure including these if they extend the profile.

Final Thoughts: Accuracy Builds Trust

Accurately determining box dimensions is more than a technical task—it’s a commitment to efficiency, cost control, and professionalism. Whether you’re a solo entrepreneur shipping handmade goods or managing a national distribution network, precision in measurement translates directly to reliability in delivery. Take the extra minute to measure correctly. Standardize your process. Train your team. The savings—and satisfaction—are measurable.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?