Building a car from scratch is no longer limited to engineering labs or major manufacturers. With the right knowledge, tools, and materials, passionate enthusiasts can design and assemble a fully functional vehicle tailored to their performance goals and aesthetic preferences. Whether you're constructing a custom hot rod, an electric prototype, or a lightweight track machine, understanding the core components, sourcing quality materials, and following proven methods are essential. This guide walks through every phase of the build process with actionable advice, expert insights, and practical checklists.

Selecting the Right Materials for Performance and Safety

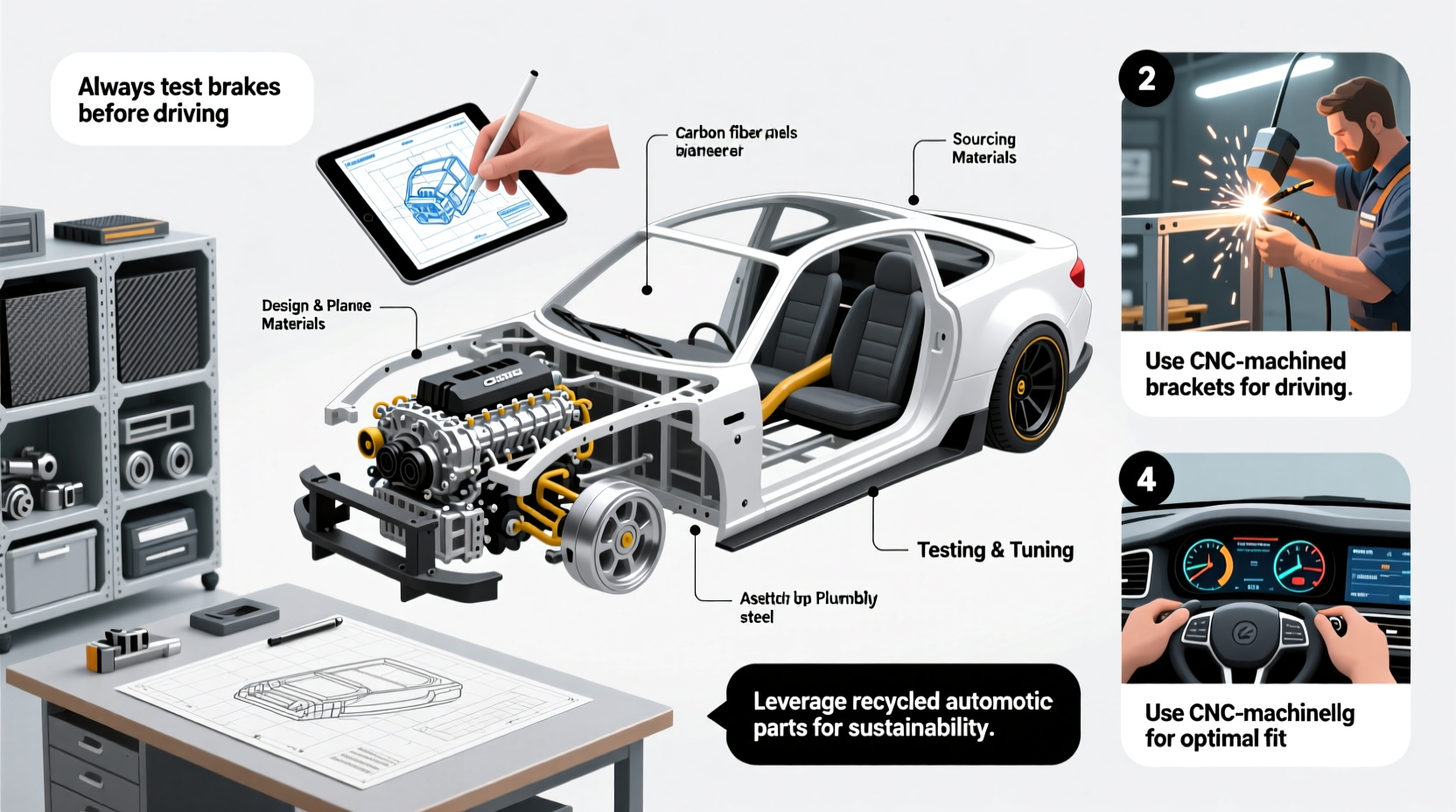

The foundation of any successful DIY car build lies in material selection. The choices you make directly impact durability, weight, fuel efficiency, safety, and overall driving dynamics. While steel remains a common choice for frames due to its strength and weldability, many builders now opt for chromoly steel or aluminum to reduce weight without sacrificing rigidity.

Body panels can be crafted from fiberglass, carbon fiber, or sheet metal. Fiberglass is cost-effective and easy to shape but less durable under impact. Carbon fiber offers superior strength-to-weight ratio and a high-end finish but comes at a premium price. Steel body panels are heavier but more repairable and resistant to cracking.

For suspension and drivetrain components, forged alloy parts provide better fatigue resistance than cast alternatives. Brake lines should be stainless steel braided for consistent pressure and longevity. Interior materials like fire-resistant upholstery and sound-dampening insulation contribute to both comfort and safety.

Essential Components and Sourcing Strategy

Before cutting metal or welding joints, compile a comprehensive list of required components. Many builders source parts from donor vehicles, salvage yards, or aftermarket suppliers. Using a donor car—such as a Subaru WRX for its AWD system or a Porsche 914 for its mid-engine layout—can save time and ensure compatibility.

| Component | Recommended Source | Budget Option | Premium Option |

|---|---|---|---|

| Chassis/Frame | Donor vehicle or tube chassis kit | Used unibody shell | Custom TIG-welded space frame |

| Engine | Rebuilt crate engine | Salvage yard pull | Tuned performance engine (LS3, EJ25) |

| Transmission | Aftermarket manual gearbox | Used transmission rebuild | Sequential racing gearbox |

| Suspension | Coilover kits (KW, BC Racing) | Modified OEM struts | Double-wishbone independent setup |

| Electrical System | Modern harness kits (Painless, Ron Francis) | Donor wiring reuse | Custom CAN-bus digital network |

When sourcing materials, verify part condition thoroughly. Test engines on a dyno if possible, inspect suspension arms for cracks, and replace rubber bushings proactively. Keep receipts and documentation for traceability, especially if registering the vehicle for road use.

Step-by-Step Build Process Timeline

A methodical approach prevents costly errors and keeps the project on track. Follow this logical sequence to maintain momentum and structural coherence.

- Design & Planning (Weeks 1–4): Define purpose (street, track, off-road), sketch layouts, select wheelbase and drivetrain configuration. Use CAD software for mockups if available.

- Acquire Donor or Frame (Weeks 5–6): Strip usable parts (ECU, gauges, differentials) before dismantling. Inspect for rust and structural damage.

- Build or Modify Chassis (Weeks 7–12): Weld subframes, mount suspension points, install roll cage if needed. Conduct alignment checks.

- Install Powertrain (Weeks 13–16): Mount engine and transmission. Connect driveshafts, cooling lines, and exhaust routing.

- Plumb Systems (Weeks 17–18): Run fuel lines, brake hydraulics, and coolant hoses. Pressure-test all connections.

- Electrical Integration (Weeks 19–21): Wire ignition, lighting, sensors, and dash electronics. Use relays and fuses for circuit protection.

- Bodywork & Finishing (Weeks 22–26): Fit panels, sand, prime, and paint. Install glass, trim, and seals.

- Final Assembly & Testing (Weeks 27–30): Add interior, wheels, and fluids. Perform startup, brake, and handling tests in a secure area.

Expert Insight: Learning from Real Builds

Professional fabricator Marcus Reed, who has led over 30 custom vehicle builds at Velocity Dynamics Workshop, emphasizes precision over speed.

“Most failed builds stem from skipping alignment steps or rushing electrical work. Take the time to set your suspension geometry correctly—even half a degree off can ruin tire wear and handling.” — Marcus Reed, Automotive Fabrication Specialist

He also recommends investing in basic metrology tools like a laser alignment kit and digital torque wrench. “These aren’t luxuries—they’re what separate a garage project from a roadworthy machine.”

Mini Case Study: Building a Lightweight Roadster

In 2022, hobbyist engineer Diego Martinez completed a DIY roadster using a Mazda Miata donor and a custom aluminum space frame. His goal was a sub-2,000-pound vehicle with balanced handling.

Diego sourced a used 1.8L Miata engine and transmission, then designed a simplified tubular chassis using CAD software. He fabricated the frame himself with rented TIG welding equipment, reinforcing critical stress points near the suspension mounts.

To save weight, he used polycarbonate windows and hand-laid fiberglass body panels. Electrical systems were simplified with a modern aftermarket harness. After 11 months and approximately $14,000 in parts and tool rentals, the car passed state inspection and achieved 38 mpg on highways.

His biggest lesson? “Test-fit everything before final welding. I had to cut and reposition the steering column twice because I didn’t mock it up with the actual rack.”

Dos and Don'ts of DIY Car Building

| Do | Don't |

|---|---|

| Mock up components before permanent installation | Assume factory bolt patterns will align perfectly |

| Use thread locker on critical fasteners | Overtighten suspension bolts without proper torque specs |

| Ground electrical systems to clean, unpainted metal | Route fuel lines near exhaust components |

| Label wires and document modifications | Ignore local DMV regulations for homemade vehicles |

| Test systems incrementally (e.g., brakes before startup) | Start the engine without verifying oil and coolant flow |

Frequently Asked Questions

Can I legally register a car I build myself?

Yes, in most U.S. states and many countries, homebuilt vehicles can be registered under “special construction” or “amateur-built” classifications. Requirements typically include proof of ownership of parts, a completed inspection, and sometimes a visual verification of craftsmanship. Check with your local DMV for specific rules.

How much does it cost to build a car from scratch?

Costs vary widely based on complexity and sourcing. A basic kit car or donor-based build may range from $8,000 to $15,000. High-performance or electric conversions can exceed $30,000. Factor in tooling, safety gear, and unexpected repairs when budgeting.

Do I need welding experience to build a car?

While not mandatory, welding proficiency—especially TIG or MIG—is highly recommended for chassis and structural work. If you lack experience, consider taking a course or partnering with a certified welder for critical joints.

Final Checklist Before First Start

- ✅ Confirm all fluid levels (oil, coolant, brake fluid, power steering)

- ✅ Verify battery is charged and grounded properly

- ✅ Ensure fuel system is leak-free and primed

- ✅ Double-check ignition and ECU connections

- ✅ Inspect tires, lug nuts, and suspension links

- ✅ Clear the test area and have a fire extinguisher nearby

- ✅ Perform a cranking test without spark plugs to check oil pressure build-up

Conclusion

Building your own car is one of the most rewarding challenges a mechanical enthusiast can undertake. It blends engineering, craftsmanship, and personal vision into a tangible, drivable result. By selecting appropriate materials, following a structured build timeline, and learning from experienced builders, you can turn ambition into reality. Every bolt tightened and wire connected brings you closer to a vehicle that’s truly yours—not just in ownership, but in creation.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?