Bowling is as much about finesse and feel as it is about power and precision. While most players focus on their swing mechanics or ball selection, few pay close attention to the foundation of every shot: their shoes. The soles of bowling shoes are engineered for specific sliding dynamics, but over time, they degrade—especially under heavy use. Enter an old-school solution that’s gaining modern traction: bear grease. Used for generations in outdoor gear maintenance, bear grease offers unique conditioning properties that can extend the life and improve the performance of leather-based bowling shoes. This guide explores why and how to properly condition your bowling footwear using bear grease, ensuring consistent slide control, longevity, and a competitive edge.

The Science Behind Slide and Sole Integrity

The performance of a bowling shoe hinges on its ability to manage friction. One shoe features a smooth sole for sliding during delivery, while the other provides traction. These soles are typically made from specialized suede or microfiber materials bonded to leather uppers. Over time, repeated exposure to dust, moisture, temperature shifts, and physical stress causes the leather to dry out, crack, and lose structural integrity. This degradation affects not only comfort but also balance and consistency in approach.

Natural fats like bear grease penetrate deep into leather fibers, replenishing lost oils and preventing brittleness. Unlike synthetic conditioners that sit on the surface, animal-based tallow binds at a molecular level with collagen in the leather, restoring flexibility without compromising breathability. Bear grease, specifically, has a high melting point and low oxidation rate, making it ideal for long-term protection—even under fluctuating conditions found in bowling alleys.

“Properly conditioned leather maintains elasticity and resists wear far longer than untreated material. For athletes relying on equipment consistency, this isn’t just maintenance—it’s performance optimization.” — Dr. Alan Reeves, Materials Scientist & Sports Gear Consultant

Why Bear Grease? Comparing Conditioning Agents

Not all leather conditioners are created equal. Many commercial products contain silicones or petroleum derivatives that temporarily soften leather but eventually clog pores and accelerate deterioration. Natural alternatives like mink oil or neatsfoot oil are popular, but each comes with trade-offs.

| Conditioner Type | Penetration Depth | Water Resistance | Suitability for Bowling Shoes |

|---|---|---|---|

| Bear Grease | Deep | High | Excellent – preserves slide zone integrity |

| Mink Oil | Moderate | Medium | Good – may darken leather slightly |

| Neatsfoot Oil | Deep | Low-Medium | Fair – can become rancid over time |

| Synthetic Conditioners | Surface-only | Variable | Poor – often creates slick residue affecting sole adhesion |

Bear grease stands out due to its stability, biocompatibility with leather, and resistance to microbial breakdown. When applied correctly, it conditions without oversaturating, maintaining the precise texture needed for reliable shoe function.

Step-by-Step: Conditioning Your Bowling Shoes with Bear Grease

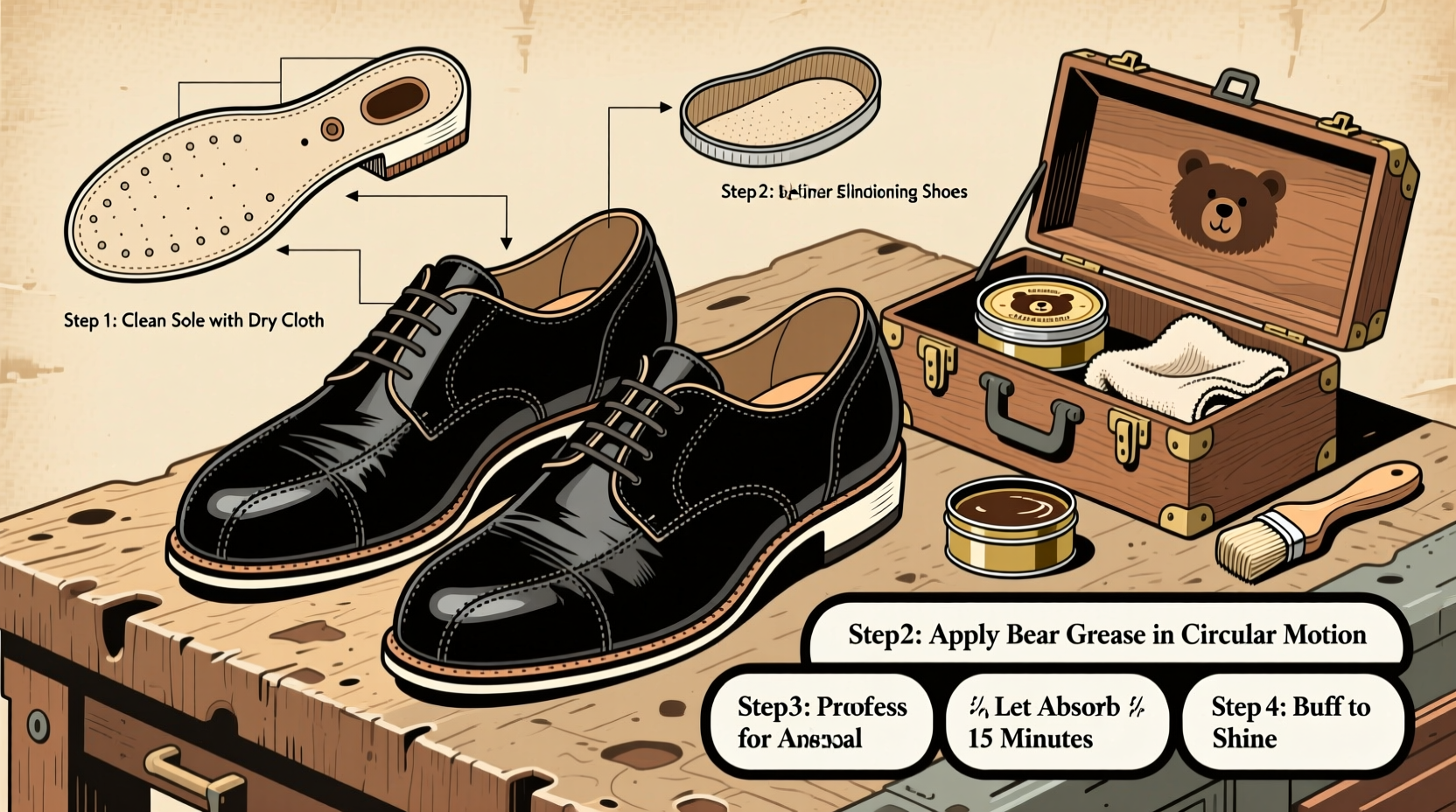

Applying bear grease is simple but requires patience and precision. Follow this timeline to maximize results without damaging your gear.

- Preparation (Day 1): Remove laces and clean the entire shoe with a dry brush and damp cloth. Focus on seams and creases where dirt accumulates. Allow shoes to air-dry completely—never apply grease to moist leather.

- Application (Day 2): Using a soft cotton rag or applicator pad, rub a pea-sized amount of purified bear grease onto the leather upper in circular motions. Work in small sections, avoiding the sole and toe cap unless specified by manufacturer guidelines.

- Soaking Period (24–48 hours): Place shoes in a breathable fabric bag and store them in a cool, dark place. This allows the grease to fully absorb into the grain layer.

- Buffing (Day 3 or 4): Wipe off any residual surface oil with a clean cloth. Buff gently with a dry chamois to restore sheen and remove stickiness.

- Performance Test (After Conditioning): Walk on a non-slip surface to assess feel. Then perform light approach drills on the approach board to confirm that slide behavior remains consistent.

Repeat this process every 6–8 weeks during active play seasons. Off-season storage should include a final conditioning treatment before placing shoes in a ventilated container away from direct heat sources.

Real-World Application: A League Bowler’s Experience

Daniel Reyes, a 14-year league bowler from Milwaukee, struggled with frequent cracking along the heel counter of his premium bowling shoes. Despite rotating pairs, he replaced them annually due to stiffness and discomfort. After learning about traditional leather care methods from a hunting outfitter, he experimented with food-grade bear grease sourced from a reputable supplier.

He followed the conditioning steps meticulously, applying the grease twice per season. Within three months, he noticed improved flexibility and reduced foot fatigue. More importantly, his slide became smoother and more predictable. “It felt like breaking in a new pair—but without losing the muscle memory I’d built,” Daniel said. His current pair has lasted 22 months with no structural issues, nearly doubling his previous average lifespan.

Best Practices and Common Mistakes to Avoid

- Use only purified, odorless bear grease – raw or unfiltered versions may attract pests or develop unpleasant smells.

- Never apply near the sole edges – excess grease can transfer to the approach, creating hazardous slip zones.

- Avoid heat guns or hair dryers – artificial heat forces uneven absorption and can warp leather.

- Do not mix with synthetic sprays – chemical interactions may degrade both the conditioner and the material.

Checklist: Preparing and Applying Bear Grease Safely

- ☐ Confirm your bowling shoes have genuine leather uppers (not synthetic).

- ☐ Purchase purified, refined bear grease from a trusted source. <3>☐ Clean shoes thoroughly and allow full drying time.

- ☐ Apply grease sparingly—start with less, add more if needed after 24 hours.

- ☐ Keep away from slide soles and non-leather components.

- ☐ Let shoes rest undisturbed for at least 24 hours post-application.

- ☐ Buff and inspect before returning to play.

Frequently Asked Questions

Can bear grease affect my slide on the lane?

No—if applied correctly to the upper only. The key is avoiding contact with the sole or outsole areas. Never walk on carpeted or approach surfaces immediately after application until all residue is removed.

Where can I buy safe, usable bear grease for this purpose?

Look for cosmetic-grade or taxidermy supply stores that sell odorless, filtered bear grease. Some outdoor retailers and online specialty shops offer it in small jars labeled for leather preservation. Avoid industrial or unprocessed forms.

Are there ethical concerns with using bear grease?

This depends on sourcing. Choose suppliers who obtain fat as a byproduct of regulated hunting or meat processing, not those supporting trophy hunting or unsustainable practices. Alternatively, consider high-grade alternatives like bison tallow, which offer similar benefits.

Conclusion: Elevate Your Game From the Ground Up

Your bowling shoes do more than protect your feet—they’re integral to your form, timing, and consistency. Treating them with respect means going beyond wiping down soles after games. Conditioning with bear grease is a time-tested method that aligns tradition with performance science. By investing a small amount of effort into proper care, you preserve not just the material, but the reliability of your game.

Whether you're chasing a perfect series or simply enjoying weekly recreation, remember that excellence often lies in overlooked details. Take ownership of your equipment. Condition with intention. Step onto the approach with confidence—not just in your swing, but in every part of your foundation.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?