Oxygen sensors are critical components in modern vehicle emission control systems. While many drivers know their car has oxygen (O2) sensors, few understand the distinction between upstream and downstream variants — or why their placement is so important. These sensors may look similar and serve related purposes, but their roles, locations, and impact on engine function differ significantly. Confusing one for the other can lead to misdiagnosis, poor fuel economy, and failed emissions tests.

This article breaks down the technical and practical differences between upstream and downstream O2 sensors, explains how each contributes to engine management, and clarifies why location isn’t just a detail — it’s fundamental.

Understanding Oxygen Sensors: The Basics

Oxygen sensors measure the amount of unburned oxygen in the exhaust gases exiting the engine. This data helps the engine control unit (ECU) determine whether the air-fuel mixture is too rich (excess fuel) or too lean (excess air). By adjusting fuel delivery in real time, the ECU maintains optimal combustion efficiency, reduces harmful emissions, and improves fuel economy.

There are typically two types of O2 sensors in most vehicles with catalytic converters:

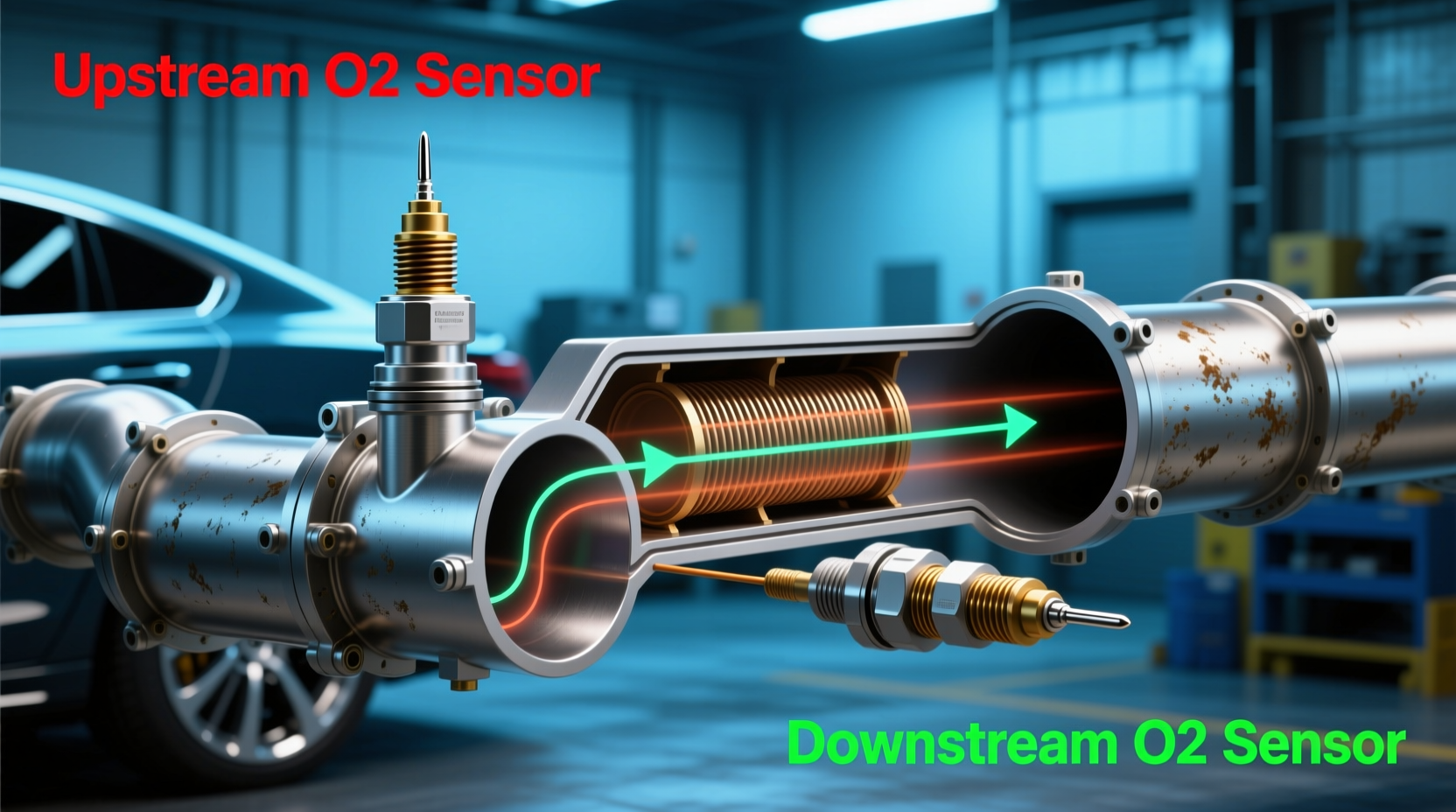

- Upstream O2 sensor – Located before the catalytic converter.

- Downstream O2 sensor – Positioned after the catalytic converter.

Despite both measuring oxygen levels, their purposes diverge significantly due to placement and timing within the exhaust system.

The Role of the Upstream O2 Sensor

The upstream sensor, also known as Sensor 1, is mounted in the exhaust manifold or close to the engine. It monitors the oxygen content in exhaust gases immediately after combustion but before they enter the catalytic converter.

This sensor provides live feedback to the ECU about the air-fuel ratio. Its readings are used in what's called \"closed-loop fuel control.\" When the engine warms up, the ECU switches from open-loop (pre-programmed fuel delivery) to closed-loop mode, where it actively adjusts injector pulse width based on upstream O2 sensor input.

A properly functioning upstream sensor ensures that the engine runs near the ideal stoichiometric ratio of 14.7:1 (air to fuel), maximizing combustion efficiency and minimizing pollutants like carbon monoxide and hydrocarbons.

The Function of the Downstream O2 Sensor

The downstream O2 sensor, or Sensor 2, sits after the catalytic converter. Unlike the upstream sensor, it doesn't directly influence fuel mixture adjustments. Instead, its primary role is to monitor the efficiency of the catalytic converter.

In a properly working system, the catalytic converter should reduce the amount of oxygen fluctuation in the exhaust stream. The upstream sensor shows rapid voltage swings (typically between 0.1V and 0.9V) as the ECU toggles between rich and lean mixtures. The downstream sensor, however, should show a much more stable signal — usually around 0.45V — indicating that the catalyst is effectively storing and releasing oxygen to clean the exhaust.

If the downstream sensor begins mimicking the upstream sensor’s fluctuating pattern, it signals that the catalytic converter is no longer functioning efficiently. This often triggers diagnostic trouble codes such as P0420 or P0430 — common indicators of catalyst inefficiency.

“Many technicians replace O2 sensors without checking the full picture. A failing downstream sensor might not be the problem — it could be correctly reporting a bad catalytic converter.” — Mark Reynolds, ASE-Certified Master Technician

Key Differences: Upstream vs Downstream at a Glance

| Feature | Upstream O2 Sensor | Downstream O2 Sensor |

|---|---|---|

| Location | Before catalytic converter (exhaust manifold) | After catalytic converter |

| Primary Function | Monitor air-fuel ratio for ECU adjustments | Assess catalytic converter efficiency |

| Signal Pattern | Rapid voltage fluctuations (0.1V–0.9V) | Stable voltage (~0.45V) |

| Impact on Engine Performance | Direct — affects fuel trims and drivability | Indirect — indicates converter health |

| Common Failure Symptoms | Poor fuel economy, rough idle, hesitation | Illuminated check engine light (P0420), failed emissions |

| Replacement Priority | High — affects engine operation | Lower — unless converter is compromised |

Can You Swap Them? Why Location Matters

While upstream and downstream O2 sensors may appear physically identical — especially in older zirconia-type models — they are not interchangeable in practice. Modern sensors are often calibrated differently, and the ECU interprets their signals based on expected behavior for each position.

Swapping them or installing the wrong sensor in the wrong location can result in:

- Inaccurate fuel trim calculations

- False catalytic converter efficiency readings

- Check engine lights and driveability issues

- Failed emissions inspections

Additionally, some vehicles use wideband (air-fuel ratio) sensors upstream, which are far more complex than the narrowband sensors used downstream. These cannot be interchanged under any circumstances.

Real-World Example: Misdiagnosing a Bad Sensor

Consider a 2015 Honda Accord brought into a repair shop with a P0134 code (“O2 Sensor Circuit No Activity Detected – Bank 1, Sensor 1”). The technician assumes the upstream sensor is faulty and replaces it. However, the check engine light returns within days.

Further investigation reveals that the issue wasn’t the sensor itself, but a vacuum leak causing a lean condition so extreme that the upstream O2 sensor stopped cycling. With no variation in oxygen levels, the ECU interpreted the signal as “no activity.” Replacing the sensor didn’t fix the root cause.

This case illustrates why understanding sensor function and context matters. A sensor may be perfectly functional but unable to respond due to external engine issues. Blind replacement leads to wasted time and money.

Step-by-Step Guide to Diagnosing O2 Sensor Issues

- Scan for trouble codes – Use an OBD2 scanner to identify which sensor is flagged.

- Determine sensor position – Confirm whether it’s upstream (Sensor 1) or downstream (Sensor 2).

- Inspect live data – Using a scan tool, observe voltage patterns:

- Upstream should cycle rapidly between 0.1V and 0.9V.

- Downstream should remain relatively steady.

- Check fuel trims – Long-term and short-term fuel trims outside ±10% suggest upstream sensor or related system issues.

- Test heater circuits – Many O2 sensors have internal heaters; test resistance and power supply.

- Verify exhaust integrity – Leaks before the upstream sensor can skew readings.

- Replace only when necessary – Don’t replace sensors based on age alone; use data to confirm failure.

Frequently Asked Questions

Can a bad upstream O2 sensor damage the catalytic converter?

Yes. If the upstream sensor fails and causes the engine to run excessively rich, unburned fuel enters the exhaust and overheats the catalytic converter. This can melt the catalyst substrate, leading to clogging or complete failure.

Do all cars have both upstream and downstream O2 sensors?

Most vehicles manufactured after 1996 (post-OBD2 standardization) have at least one upstream and one downstream sensor per bank. High-performance or V6/V8 engines may have multiple sensors on each side.

How long do O2 sensors last?

Upstream sensors typically last 60,000 to 100,000 miles. Downstream sensors often last longer due to less exposure to extreme temperature swings and contaminants. However, harsh driving conditions can shorten lifespan.

Conclusion: Location Is Everything

The difference between upstream and downstream O2 sensors isn’t just about placement — it’s about purpose. The upstream sensor is a dynamic regulator of engine performance, while the downstream sensor acts as a diagnostic sentinel for emissions control. Treating them as interchangeable or ignoring their distinct roles leads to inaccurate diagnoses and unnecessary repairs.

Understanding how each sensor works empowers you to make informed decisions, whether you're performing maintenance, interpreting check engine lights, or discussing repairs with a mechanic. These small components play oversized roles in keeping your vehicle efficient, compliant, and reliable.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?