Organic synthesis is both an art and a science—where strategic planning meets chemical intuition. One of the most common challenges students and researchers face is determining the optimal reaction sequence to achieve a desired molecular transformation. Whether you're converting a simple alkene into a functionalized alcohol or building complex polycyclic frameworks, selecting the right pathway can mean the difference between high yield and total failure. This article breaks down the logic behind choosing effective reaction sequences, highlights widely trusted methods, and provides real-world context to guide your synthetic decisions.

Understanding the Goal: Defining the Transformation

Before evaluating any reaction sequence, it's essential to clearly define the starting material and the target molecule. A transformation isn't just about changing functional groups—it often involves controlling regiochemistry, stereochemistry, and avoiding side reactions. For instance, turning benzyl alcohol into phenylacetic acid requires more than oxidation; it demands a two-step process involving activation and carbon chain extension.

The key is retrosynthetic analysis: working backward from the target to identify logical disconnections. Each bond formed should correspond to a known, reliable reaction. Consider the transformation of cyclohexanol to adipic acid—a classic example in industrial chemistry. The most efficient path involves nitric acid oxidation, but alternative lab-scale sequences using periodate cleavage after diol formation offer better selectivity.

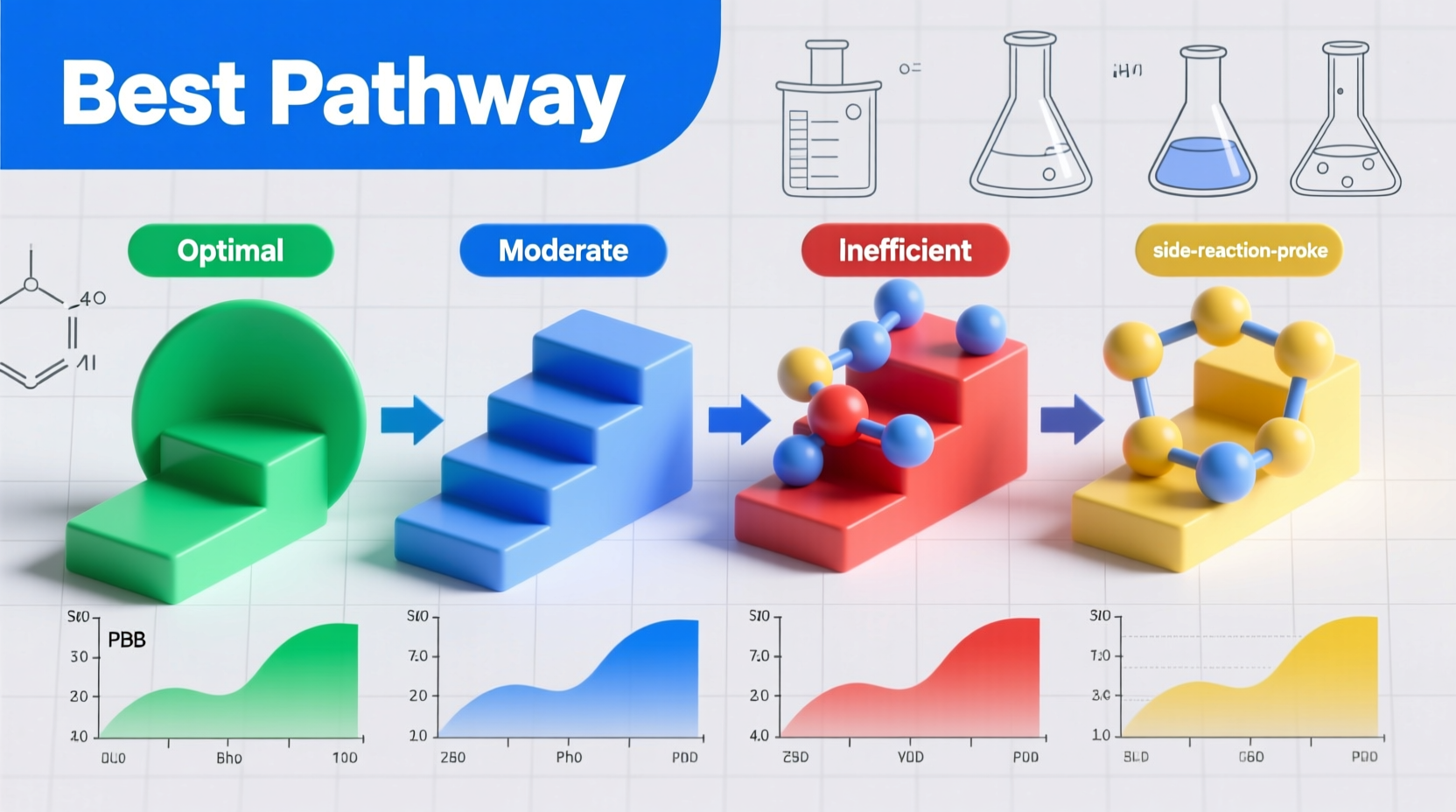

Popular Reaction Sequences and Their Applications

Certain sequences have earned their place as go-to solutions due to reliability, scalability, and broad substrate tolerance. Below are some of the most widely adopted pathways in modern organic synthesis.

1. Grignard Formation Followed by Nucleophilic Addition

This two-step sequence converts alkyl halides to alcohols via organomagnesium intermediates. For example, transforming bromoethane into 1-phenylpropan-1-ol involves forming the Grignard reagent, then adding it to benzaldehyde. The reaction is highly predictable and works well with aromatic and aliphatic aldehydes.

2. Hydroboration-Oxidation for Anti-Markovnikov Alcohols

When the goal is to add water across a double bond with anti-Markovnikov orientation and syn stereochemistry, hydroboration-oxidation remains unmatched. It’s particularly valuable in synthesizing primary alcohols from terminal alkenes without rearrangement issues seen in acid-catalyzed hydration.

3. Wittig Reaction After Aldehyde Formation

To extend carbon chains and introduce alkenes, the Wittig sequence is indispensable. Start with an alcohol, oxidize to aldehyde (e.g., using PCC), then react with a phosphonium ylide. This method offers precise control over double bond position and is widely used in natural product synthesis.

4. Gabriel Synthesis for Primary Amines

Direct alkylation of ammonia leads to overalkylation, but the Gabriel route avoids this by using phthalimide as a protected nitrogen source. After alkylation, hydrazine releases the primary amine cleanly—ideal for preparing amino acids or pharmaceutical intermediates.

“Efficiency in synthesis isn’t just about step count—it’s about minimizing purification, maximizing yield, and preserving functionality.” — Dr. Lena Patel, Organic Process Chemist at Merck Research Labs

Step-by-Step Guide: Designing Your Optimal Sequence

Choosing the best reaction sequence isn’t guesswork. Follow this structured approach to evaluate and select the most effective pathway.

- Analyze Functional Group Interconversion (FGI): Identify which groups must be added, removed, or modified.

- Check Compatibility: Ensure reagents in one step won’t interfere with existing functionalities later (e.g., LiAlH₄ reduces esters but also nitriles).

- Evaluate Regio- and Stereocontrol: Choose reactions that deliver the correct isomer—enzymatic reductions or Sharpless epoxidations may be superior to non-selective alternatives.

- Minimize Steps and Purifications: Convergent syntheses and tandem reactions reduce time and increase overall yield.

- Scale and Safety Considerations: Avoid toxic reagents (e.g., OsO₄) or explosive intermediates (azides) unless strictly controlled.

Example Timeline: Converting Toluene to p-Nitrobenzoic Acid

- Week 1: Oxidize methyl group using KMnO₄ → benzoic acid

- Week 2: Protect acid as methyl ester (CH₂N₂)

- Week 3: Nitrate with HNO₃/H₂SO₄ → methyl p-nitrobenzoate (directs para due to ester group)

- Week 4: Hydrolyze ester under basic conditions → p-nitrobenzoic acid

This four-step sequence avoids the problem of over-oxidation and ensures proper regioselectivity through strategic protection.

Comparison Table: Common Transformation Pathways

| Transformation | Recommended Sequence | Advantages | Limitations |

|---|---|---|---|

| Alkene → Alcohol (anti-Markovnikov) | Hydroboration → Oxidation (H₂O₂/OH⁻) | No carbocation rearrangements, syn addition | Borane handling requires care |

| Primary Alcohol → Carboxylic Acid | KMnO₄ or Jones reagent (CrO₃/H₂SO₄) | High yield, works on sensitive substrates | Chromium waste is environmentally hazardous |

| Nitrile → Amine | LiAlH₄ reduction | Complete conversion, fast | Not compatible with esters or acids |

| Alkyl Halide → Alkene | E2 elimination with strong base (e.g., t-BuOK) | Zaitsev product favored, scalable | Possible competition with substitution |

| Aromatic Ring → Sulfonic Acid | Sulfonation with conc. H₂SO₄ or SO₃ | Reversible, useful for blocking positions | Requires elevated temperatures |

Mini Case Study: Synthesizing Ibuprofen in Three Steps

A classic example of an optimized reaction sequence is the Boots synthesis of ibuprofen. Starting from isobutylbenzene, the transformation proceeds as follows:

- Friedel-Crafts acylation with acetyl chloride/AlCl₃ → p-isobutylacetophenone

- Darzens glycidic ester reaction followed by hydrolysis/decarboxylation → aldehyde intermediate

- Oxidation to carboxylic acid → ibuprofen

Later improvements by BHC streamlined this to just two catalytic steps using palladium-catalyzed carbonylation, increasing atom economy from 40% to over 95%. This case underscores how evolving methodology can drastically improve efficiency.

Expert Tips for Maximizing Success

Frequently Asked Questions

How do I choose between similar reaction sequences?

Compare factors like yield, availability of reagents, safety profile, and number of purification steps. For academic work, elegance and novelty matter; for industry, cost and scalability dominate.

Can I skip purification between steps?

Sometimes yes—if the byproducts don’t interfere with the next reaction. Telescoping steps (running reactions without isolation) is common in process chemistry but requires careful optimization.

What if my sequence gives low yield?

Re-evaluate each step: check stoichiometry, temperature, reaction time, and moisture levels. Often, a single bottleneck step drags down the entire sequence.

Final Checklist Before Running Your Sequence

- ☑ All starting materials are pure and dry

- ☑ Solvents are appropriate and degassed if needed

- ☑ Reagents are fresh (especially hydrides and organometallics)

- ☑ Protective equipment and waste disposal plans are in place

- ☑ Analytical methods (TLC, NMR, IR) are ready for monitoring

Conclusion

Selecting the best reaction sequence for a given transformation hinges on deep understanding, not memorization. While popular routes like Grignard additions or hydroboration-oxidation offer reliable outcomes, the ideal path depends on your specific substrate, constraints, and goals. By applying systematic retrosynthetic thinking, leveraging proven methodologies, and learning from real-world cases, you can design sequences that are not only effective but elegant and sustainable.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?