The air conditioning capacitor is a small but critical component in your HVAC system. It provides the electrical boost needed to start the compressor and fan motor, ensuring smooth operation during hot weather. Despite its compact size, a failing capacitor can bring your cooling system to a halt. Understanding why AC capacitors fail, recognizing early warning signs, and knowing how to respond can save you from costly repairs and uncomfortable indoor temperatures.

What an AC Capacitor Does

The capacitor stores and releases electrical energy to help motors overcome initial resistance when starting up. Most residential AC units use two types of capacitors: the start capacitor, which gives a powerful jolt to initiate motor rotation, and the run capacitor, which maintains a steady energy supply to keep the motor running efficiently. Some systems use a dual-run capacitor that handles both the compressor and the fan motor.

Without a functioning capacitor, the motor may struggle to start or fail entirely, leading to inconsistent cooling or complete system shutdown.

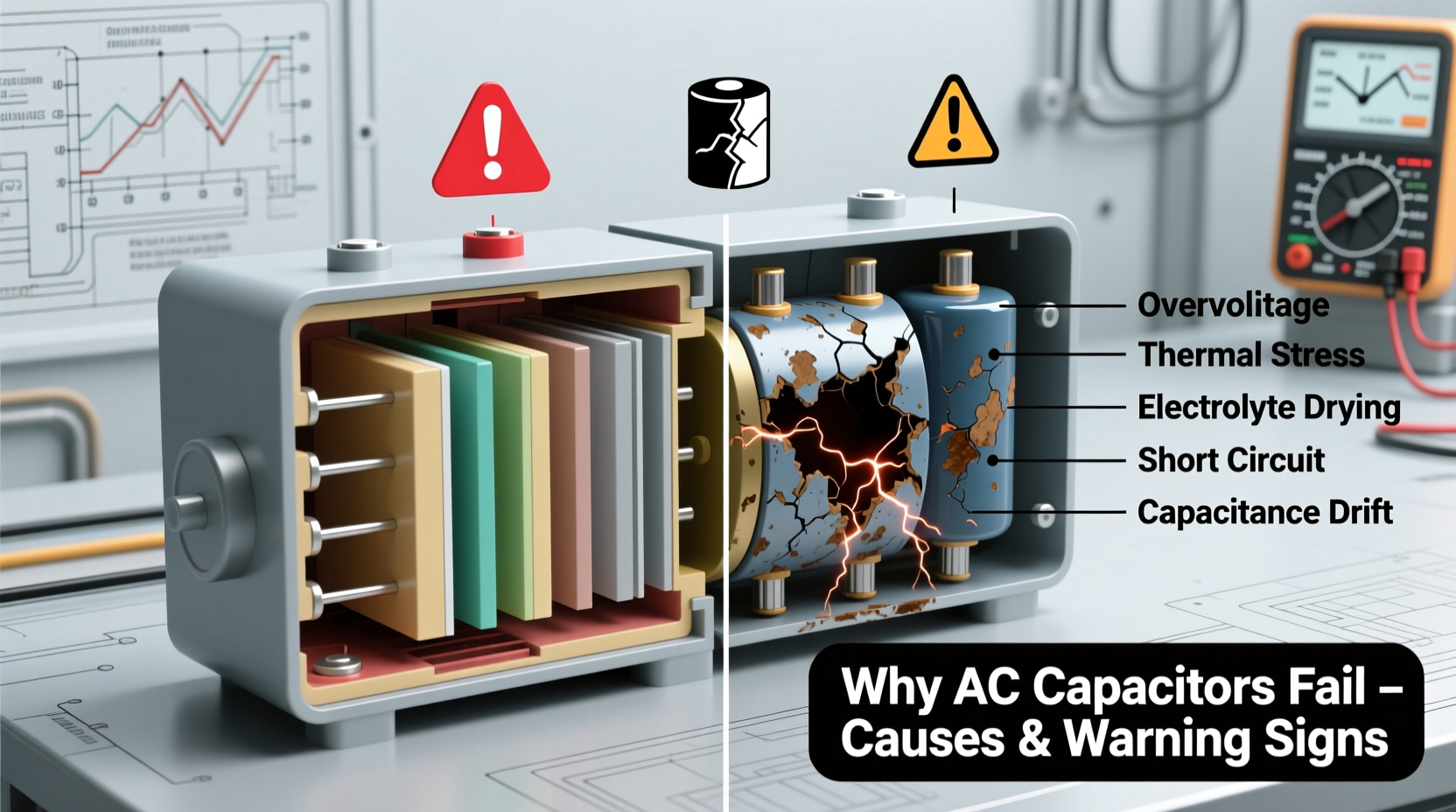

Common Causes of AC Capacitor Failure

Capacitors don’t last forever. While they typically have a lifespan of 5 to 20 years, several factors can accelerate their deterioration.

- Heat Exposure: High ambient temperatures—especially in poorly ventilated outdoor units—can cause capacitors to overheat and degrade faster.

- Voltage Overload: Power surges or inconsistent voltage supply can damage the internal dielectric material, leading to short circuits or reduced capacitance.

- Aging and Wear: Like all electronic components, capacitors lose efficiency over time due to chemical breakdown within the electrolyte.

- Poor Installation: Incorrect wiring, loose connections, or using a capacitor with the wrong microfarad (µF) rating can lead to premature failure.

- Moisture and Corrosion: Water intrusion from rain, condensation, or poor housing seals can corrode terminals and internal components.

- Frequent Cycling: Systems that turn on and off too often place repeated stress on the capacitor, reducing its longevity.

“Capacitors are one of the most replaced parts in HVAC systems—not because they’re low quality, but because they operate under high electrical and thermal stress.” — James Ralston, HVAC Technician with 18 years of field experience

Warning Signs of a Failing AC Capacitor

Recognizing early symptoms of capacitor trouble can prevent full system breakdowns. Watch for these red flags:

- Delayed Startup: The AC takes longer than usual to kick on, or the outdoor unit hums without the fan spinning immediately.

- Weak Airflow: Reduced cooling performance even when the thermostat is set low, indicating the fan motor isn’t getting proper power.

- Humming Noise: A persistent humming sound from the outdoor unit suggests the compressor is trying to start but lacks sufficient electrical boost.

- AC Not Turning On: Complete failure to start, especially after a power outage or storm, may point to a dead capacitor.

- Bulging or Leaking Case: Physical damage such as swelling, oil leakage, or burnt marks on the capacitor casing indicates internal failure.

- Intermittent Operation: The system starts sometimes but not others, particularly during peak heat when electrical demand is highest.

Real Example: Summer Breakdown in Phoenix

In July 2023, a homeowner in Phoenix reported that their AC would run for 10 minutes, then shut down. After cooling for an hour, it would briefly restart. A technician diagnosed the issue: the dual-run capacitor was overheating due to inadequate airflow around the condenser unit, compounded by five years of continuous summer operation. Testing revealed a 30% drop in capacitance. Replacing the capacitor and cleaning the unit restored full function—preventing a $1,200 compressor replacement caused by repeated hard starts.

How to Prevent Premature Capacitor Failure

While capacitors eventually wear out, proactive care can extend their service life significantly.

| Action | Benefit | Frequency |

|---|---|---|

| Keep condenser unit clean and shaded | Reduces heat exposure and improves airflow | Twice yearly |

| Install a surge protector | Prevents voltage spikes from damaging electronics | One-time installation |

| Check and tighten electrical connections | Minimizes arcing and resistance buildup | Annually |

| Test capacitance with a multimeter | Detects weakening before total failure | Every 2 years or during tune-ups |

| Ensure correct capacitor specifications | Prevents mismatch-related stress | During replacements |

Step-by-Step: How Technicians Test a Capacitor

If you suspect capacitor issues, a qualified HVAC technician will follow this process:

- Turn off power at the breaker to ensure safety.

- Discharge the capacitor using a resistor or insulated screwdriver to prevent electric shock.

- Disconnect wires and remove the capacitor from the unit.

- Inspect visually for bulges, leaks, or burn marks.

- Use a multimeter set to microfarads (µF) to measure capacitance.

- Compare reading to the rated value on the capacitor label (acceptable range is usually ±6%).

- Replace if out of spec or showing physical damage.

FAQ: Common Questions About AC Capacitor Failure

Can I replace the capacitor myself?

While technically possible, replacing an AC capacitor involves handling live electrical components and requires precise matching of voltage and capacitance ratings. Unless you have electrical training and the right tools, it’s safer and more reliable to hire a licensed HVAC technician.

How much does a capacitor replacement cost?

On average, replacing an AC capacitor costs between $150 and $400, including labor. Dual-run capacitors tend to be slightly more expensive than single ones. Costs vary by region, brand, and service provider.

Will a bad capacitor damage other parts of my AC?

Yes. A failing capacitor forces the compressor and fan motor to work harder during startup, increasing mechanical stress and heat. Over time, this can lead to premature motor burnout—a far more expensive repair than a simple capacitor swap.

Conclusion: Act Early, Save Time and Money

AC capacitor failure is one of the most common—and preventable—HVAC issues. By understanding the causes and recognizing the warning signs, homeowners can avoid unexpected breakdowns during peak cooling season. Regular maintenance, proper installation, and timely replacements are key to keeping your system running efficiently.

Don’t wait for a sweltering day to discover your AC won’t start. Schedule annual inspections, monitor for unusual sounds or performance drops, and address capacitor issues at the first sign of trouble. Your comfort and wallet will thank you.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?