Mirrors are more than just functional objects—they serve as design elements, optical tools, and even status symbols in modern homes and commercial spaces. Yet many people are surprised by the high price tags on certain mirrors, especially when compared to mass-produced alternatives. The cost of a mirror isn't arbitrary; it's shaped by a combination of materials, manufacturing techniques, size, design complexity, and finishing quality. Understanding these factors helps explain why some mirrors cost hundreds or even thousands of dollars, while others remain budget-friendly.

Material Quality and Glass Type

The foundation of any mirror is its glass, and not all glass is created equal. High-end mirrors use low-iron or \"opti-white\" glass, which reduces the greenish tint common in standard float glass. This results in truer color reflection and enhanced clarity, making the image appear brighter and more natural—especially important in well-lit environments or luxury interiors.

Low-iron glass can increase material costs by 30% to 50% compared to standard glass. Additionally, thicker glass (such as 6mm or 8mm instead of the typical 4mm) adds both durability and visual weight, contributing to higher production and shipping costs. Thicker glass also requires more precise handling during silvering and cutting, increasing labor expenses.

Manufacturing Process and Silvering Technology

The reflective backing—commonly referred to as \"silvering\"—is a critical step in mirror production. Traditional methods involve depositing a thin layer of silver or aluminum onto the back of the glass, followed by protective copper and paint layers. The precision of this process directly affects reflectivity, longevity, and resistance to tarnishing.

High-quality mirrors undergo vacuum metallization, where aluminum is vaporized in a controlled chamber and evenly bonded to the glass. This method produces a uniform, durable coating that resists moisture and oxidation far better than cheaper spray-on alternatives. In contrast, low-cost mirrors may use chemical deposition methods that degrade faster, leading to spotting and fogging over time.

According to industry expert Daniel Reeves, a glass manufacturing consultant:

“Modern vacuum-coated mirrors can last decades without degradation, while poorly coated ones may begin to delaminate within two to three years, especially in humid areas like bathrooms.” — Daniel Reeves, Glass Coating Specialist

Size, Thickness, and Custom Dimensions

Unlike standardized furniture or decor items, mirrors are often priced exponentially with size—not linearly. A mirror twice as wide and tall has four times the surface area, requiring significantly more raw material, energy, and handling care. Large-format mirrors (e.g., floor-to-ceiling or full-wall installations) require specialized equipment for cutting, polishing, and transporting.

Thickness also plays a role. While most household mirrors are 3–4mm thick, custom or commercial-grade mirrors range from 6mm to 10mm for structural stability. These heavier mirrors demand reinforced packaging and professional installation, further increasing overall cost.

| Mirror Size (inches) | Average Cost Range | Common Use Case |

|---|---|---|

| 24 x 36 | $80 – $180 | Bathroom, entryway |

| 36 x 60 | $250 – $500 | Fitness room, bedroom accent |

| 48 x 80 | $700 – $1,400 | Floor-to-ceiling, dance studios |

| Custom Wall-Sized | $1,500+ | Luxury interiors, retail displays |

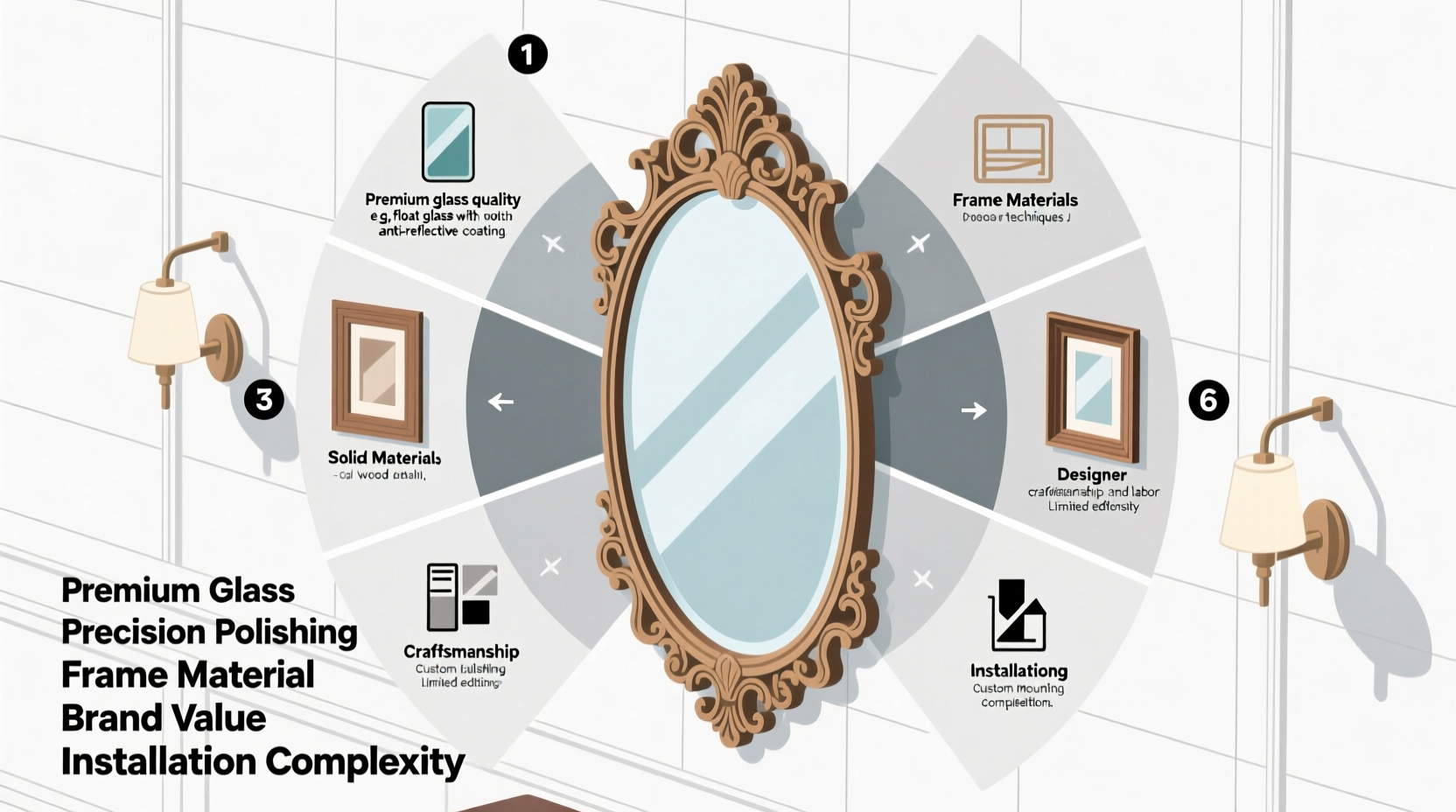

Frame Design and Craftsmanship

The frame can account for up to 60% of a mirror’s total cost, depending on materials and construction. Mass-produced framed mirrors often use molded MDF (medium-density fiberboard) with veneer finishes, which are affordable but prone to warping and chipping. In contrast, premium frames are handcrafted from solid wood, metal, or artisanal materials like bronze, reclaimed timber, or hand-carved motifs.

Hand-finishing processes such as distressing, gilding, or patina application add significant labor value. For example, a Florentine-style gold-leaf frame may require multiple layers of leafing, burnishing, and sealing by skilled artisans—each step adding days to production time.

Frameless mirrors, while appearing simpler, also carry hidden costs. Their edges must be precisely polished or beveled, a process that demands CNC machinery and expert calibration. A 15-degree bevel on a large mirror can add $100–$300 to the final price due to machine time and waste glass disposal.

Installation and Safety Considerations

Large or heavy mirrors aren’t just expensive to make—they’re costly to install safely. Professional mounting requires wall anchors, support brackets, and sometimes structural reinforcement, particularly for stone or plaster walls. Many homeowners underestimate these ancillary costs, only to face unexpected charges during installation.

Safety is another factor. Tempered glass mirrors, required in many building codes for large or overhead installations, undergo heat treatment to increase strength and reduce injury risk if broken. This process increases production time and energy use, adding 20–30% to base costs.

Real-World Example: The Designer Bathroom Project

A homeowner in Portland, Oregon, recently commissioned a custom LED-backlit mirror for their master bathroom. The initial quote came in at $2,200—far above expectations. Upon review, the breakdown revealed:

- $600 for 6mm low-iron glass with polished edges

- $400 for vacuum-aluminized coating with moisture sealant

- $500 for integrated LED lighting system with touch sensor

- $300 for walnut frame sourced from sustainable forestry

- $400 for custom crating and white-glove delivery/installation

While the upfront cost was high, the client emphasized long-term value: energy-efficient lighting, superior clarity, and a centerpiece that elevated the entire room’s aesthetic. Two years later, the mirror remains flawless despite daily bathroom humidity—a testament to quality investment.

How to Choose a Mirror That Offers Value

Not every mirror needs to be a luxury item. For practical buyers, balancing cost and quality means focusing on intended use and environment. Here’s a checklist to guide smart purchasing decisions:

✅ Mirror Selection Checklist

- Determine location: Bathrooms need moisture-resistant coatings; hallways benefit from impact-resistant glass.

- Check edge finish: Polished or beveled edges signal better craftsmanship.

- Inspect the backing: Avoid mirrors with visible bubbles, streaks, or dark spots behind the glass.

- Verify frame material: Solid wood or metal frames last longer than plastic or MDF.

- Ask about warranty: Reputable suppliers offer 5–10 year guarantees against tarnishing.

- Factor in installation: Get quotes for mounting before finalizing size and weight.

Frequently Asked Questions

Why does a small designer mirror cost more than a large department store one?

Size isn’t the only factor. Designer mirrors often use superior glass (like low-iron), advanced coatings, handcrafted frames, and rigorous quality control. A small but high-clarity mirror in a hand-finished frame can easily surpass a larger, mass-produced model in cost due to materials and labor intensity.

Do expensive mirrors last longer?

Generally, yes. Premium mirrors use corrosion-resistant backing layers and sealed edges that prevent moisture ingress—the primary cause of mirror degradation. With proper care, a high-end mirror can remain clear and reflective for 20+ years, whereas budget models may show deterioration in 3–5 years, especially in humid areas.

Is it worth repairing an old mirror instead of replacing it?

It depends. If the glass is scratched, cracked, or severely tarnished, replacement is usually more cost-effective. However, valuable antique or custom-framed mirrors can be resilvered by specialists for 40–60% of the cost of a new one. This process restores reflectivity while preserving original craftsmanship.

Final Thoughts: Investing in Clarity and Craft

Mirrors are deceptively complex products. Behind their reflective surface lies a convergence of chemistry, engineering, and artistry. The price reflects not just what you see, but how well it’s made, how long it will last, and how it enhances your space.

Whether you're selecting a simple hallway accent or commissioning a statement piece, understanding the factors behind mirror costs empowers smarter decisions. Prioritize quality where it matters—high-use areas, humid environments, or focal points in your décor. In the long run, paying more upfront often means spending less on replacements, repairs, and regrets.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?