Anyone who’s wrestled a 7.5-foot prelit artificial Christmas tree into the living room—and then compared its heft to an identical unlit model—has felt the difference firsthand. That extra 8 to 15 pounds isn’t incidental; it’s engineered weight. While manufacturers strive for realism and convenience, they also embed layers of functional hardware into every branch and trunk segment. Understanding *why* prelit trees carry more mass isn’t just trivia—it informs smarter purchasing decisions, safer setup practices, long-term storage planning, and even energy-conscious usage. This article dissects the physical contributors to that added weight, moving beyond marketing claims to examine real-world material choices, manufacturing trade-offs, and measurable engineering consequences.

The Core Weight Contributors: A Layered Breakdown

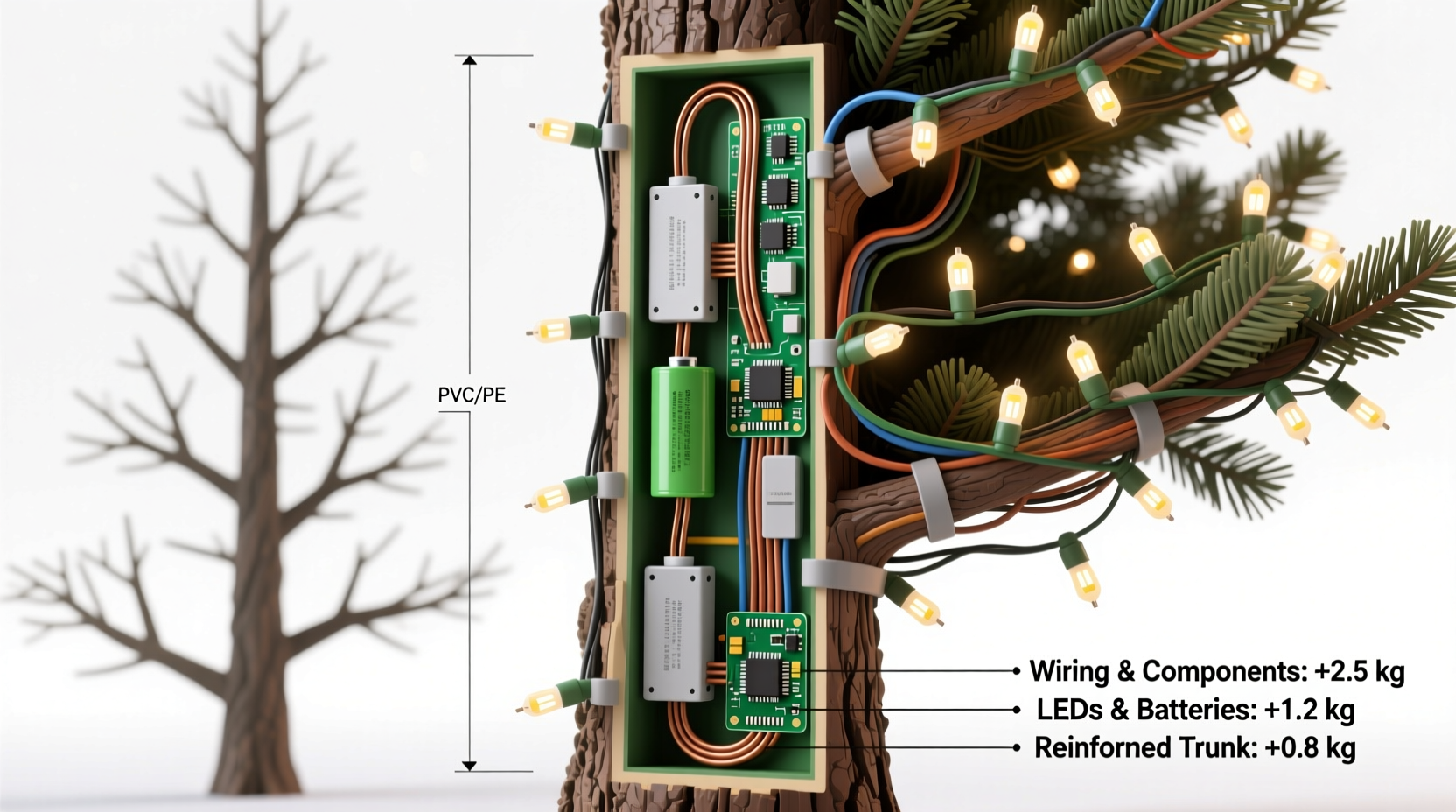

Prelit trees don’t gain weight from “extra fluff” or denser PVC needles. The difference is almost entirely attributable to integrated electrical systems and the structural adaptations required to support them safely and reliably. These components fall into five interdependent categories:

- Wiring harnesses: Insulated copper or aluminum conductors running vertically through trunks and radially along branches.

- Bulbs and sockets: LED or incandescent units, their plastic housings, metal contacts, and retention mechanisms.

- Connectors and junctions: Waterproof or weather-resistant plugs, inline fuses, and branch-to-trunk interface points.

- Control electronics: Timers, dimmers, color-changing IC chips, and sometimes remote receivers—all housed in compact enclosures.

- Structural reinforcement: Thicker trunk sleeves, reinforced branch stems, and additional internal bracing to prevent wire fatigue and strain-related failures.

Crucially, these elements aren’t additive in isolation—they compound each other. For example, thicker wiring necessitates larger-diameter branch conduits, which require stiffer plastic extrusions, which in turn demand stronger trunk joints. Each layer introduces new mass—and new engineering constraints.

Material-by-Material Mass Analysis

To quantify the impact, consider typical material densities and usage volumes across a standard 7.5-foot full-profile prelit tree (approx. 1,200–1,500 tips):

| Component | Typical Material(s) | Average Added Mass (per 7.5-ft tree) | Why It Adds Weight |

|---|---|---|---|

| Primary wiring harness | Copper (0.6–0.8 mm² gauge), PVC insulation | 1.4–2.3 lbs | Copper density (8.96 g/cm³) is over 8× that of PVC (1.3 g/cm³). Even thin-gauge wire adds up over 150+ feet of total run length. |

| Bulbs & sockets (LED) | Polycarbonate housing, brass contacts, epoxy lens, PCB substrate | 0.9–1.6 lbs | Each bulb assembly weighs 0.8–1.2 g. At 500–700 bulbs, that’s 400–840 g—plus socket bases, mounting clips, and heat sinks on premium models. |

| Branch wiring channels | Reinforced PVC or ABS tubing (0.12–0.18\" wall thickness) | 2.1–3.4 lbs | Standard unlit branches use thin-walled PE (polyethylene); prelit versions embed rigid, fire-retardant channels to protect wires—adding ~30% more plastic per branch. |

| Trunk sleeve & base | Thick-walled polypropylene with integrated wire chases, steel-reinforced base plate | 3.0–5.2 lbs | Unlit trunks rely on simple telescoping tubes. Prelit trunks must route, secure, and isolate live wiring—requiring double-wall construction and grounding provisions. |

| Controller unit & power cord | ABS housing, PCB, transformer (if AC/DC), 16 AWG cord (10–12 ft) | 0.8–1.5 lbs | Even compact controllers weigh 120–220 g. Paired with a heavy-duty cord (16 AWG = ~0.05 lbs/ft), this adds measurable heft at the base. |

Summing conservative mid-range values yields **8.2–14.0 lbs** of non-decorative, non-aesthetic mass—purely functional infrastructure. That’s equivalent to adding two medium-sized hardcover books—or a small bag of premium mulch—to the tree’s core structure.

Engineering Trade-Offs Behind the Weight Gain

Manufacturers don’t add weight arbitrarily. Every gram serves a safety, durability, or performance objective—often mandated by UL 588 (the U.S. standard for electrically operated decorative lighting). Consider three critical trade-offs:

- Safety vs. Lightness: Thinner wires reduce weight but increase resistance, leading to voltage drop, uneven brightness, and overheating. UL-compliant prelit trees use minimum-gauge wiring (typically 22–18 AWG depending on circuit length), directly increasing copper mass.

- Durability vs. Flexibility: Flexible, lightweight branch stems crack under repeated bending when wires are embedded. Reinforced stems—using higher-impact ABS or glass-filled polypropylene—resist fatigue but add 15–25% more plastic per branch.

- Functionality vs. Simplicity: A basic on/off controller adds minimal weight. But add fade effects, 16-color cycling, music sync, or app control—and you introduce microcontrollers, Bluetooth modules, capacitors, and shielding. Each component demands space, mounting, and thermal management, cascading into heavier enclosures and wiring.

Real-World Impact: A Case Study in Setup and Storage

In December 2023, Sarah M., a property manager in Portland, OR, purchased two identical 7.5-ft Fraser fir prelit trees for adjacent lobby spaces—one with warm-white LEDs and one with multicolor programmable LEDs. Both were marketed as “lightweight design.” Upon unpacking, she noticed the programmable tree weighed 13.2 lbs more than the warm-white model. Her team documented the differences:

- The programmable version used 18 AWG main trunk wiring (vs. 20 AWG in the warm-white), adding 0.9 lbs of copper alone.

- Its branches featured dual-channel wiring conduits (one for power, one for data signals), requiring 40% thicker branch stems.

- The controller housed a 12V DC transformer, Wi-Fi module, and aluminum heat sink—contributing 1.7 lbs versus the warm-white’s simple 120V timer (0.3 lbs).

- Its steel-reinforced base plate was 22% thicker to accommodate vibration dampening for motorized light sequencing.

This 13.2-lb delta translated directly into operational consequences: setup time increased by 22 minutes per tree due to handling difficulty; storage required custom reinforced shelving (standard racks buckled under stacked units); and staff reported higher fatigue during seasonal rotation. Sarah now specifies maximum weight limits (≤18 lbs for 7.5-ft trees) in procurement contracts—prioritizing UL-certified lightweight builds over feature density.

Expert Insight: What Industry Engineers Prioritize

We spoke with Derek Lin, Senior Product Engineer at a Tier-1 artificial tree manufacturer (who requested anonymity due to corporate policy), about weight optimization challenges:

“We treat every 0.1 lb as a design constraint. Reducing wire gauge saves weight but risks UL failure in thermal testing. Switching to aluminum wiring cuts mass by 30%, but increases corrosion risk and requires gold-plated contacts—raising cost 17%. Our current sweet spot is recycled copper with halogen-free flame-retardant insulation: it meets UL 588, adds only 4% weight over virgin copper, and satisfies retail sustainability mandates. The heaviest part? Not the bulbs or wires—it’s the human factor. Consumers want ‘plug-and-play’ reliability, so we over-engineer junctions and reinforce stress points. That’s where most of the ‘hidden’ weight lives.”

Practical Checklist: Evaluating Weight Before You Buy

Before committing to a prelit tree, verify these physical and specification-based indicators of responsible weight engineering:

- ✅ Check the UL label: Confirm “UL 588” (not just “UL Listed”)—this guarantees tested wiring integrity and thermal safety.

- ✅ Review wire gauge: Look for 18–20 AWG in product specs. Avoid unspecified or “proprietary” wiring—these often cut corners.

- ✅ Compare branch construction: Premium prelit trees list “reinforced stem” or “dual-layer PVC”; avoid vague terms like “premium tip” without structural details.

- ✅ Inspect the controller weight: If sold separately, a controller >0.5 lbs likely contains robust components; <0.2 lbs suggests minimal circuitry (and possibly lower durability).

- ✅ Read shipping weight, not “product weight”: Retailers often list net tree weight—but shipping weight includes packaging, base, and accessories. A 22-lb shipping weight for a 7.5-ft tree signals careful engineering; 28+ lbs may indicate overbuilt or outdated design.

FAQ: Addressing Common Concerns

Does higher weight mean better quality or safety?

Not inherently. Excessive weight can signal outdated materials (e.g., older incandescent wiring), poor weight distribution, or unnecessary over-engineering. True quality lies in UL 588 compliance, consistent brightness across branches, and verified thermal performance—not raw poundage. A well-designed modern LED tree should weigh no more than 12–14 lbs at 7.5 ft.

Can I remove the lights to reduce weight?

No—do not attempt removal. Prelit tree wiring is permanently embedded, fused, or ultrasonically welded into branches and trunks. Cutting wires voids UL certification, creates shock hazards, and almost always damages branch integrity. If weight is prohibitive, choose an unlit tree and add commercial-grade LED string lights instead.

Why do some “lightweight” prelit trees still feel heavy?

“Lightweight” marketing often refers only to the frame or stand—not total assembled weight. Many budget models use thinner plastics elsewhere to offset wiring mass, compromising durability. Always verify total packaged weight and UL certification rather than trusting descriptive labels.

Conclusion: Weight as a Design Signature—Not a Flaw

The added mass of a prelit Christmas tree is neither accidental nor avoidable—it’s the physical signature of embedded functionality, regulatory compliance, and user-centric engineering. Copper conducts electricity, plastic insulates it, metal braces support it, and silicon controls it. Every gram reflects a deliberate choice between convenience and compromise, safety and simplicity, innovation and practicality. Recognizing this transforms weight from a logistical nuisance into meaningful data: a metric that reveals how rigorously a tree was built, how thoroughly it was tested, and how thoughtfully it was intended to be used. Next time you lift a prelit tree, feel the weight not as burden—but as evidence of the invisible systems working silently to deliver light, warmth, and tradition, year after year.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?