Every holiday season, millions of households face the same quiet frustration: a single dead bulb brings down an entire string of lights—yet the bulbs can’t be swapped out. No socket, no spare, no fix. Instead of replacing one $0.12 LED, you’re forced to discard a 50-light strand that cost $25, consumed energy for years, and contributed to landfill waste. This isn’t accidental design—it’s intentional engineering shaped by cost pressures, safety mandates, miniaturization trends, and shifting consumer expectations. Understanding *why* lights became non-replaceable—and what you can realistically do to preserve them—isn’t just about saving money. It’s about reducing seasonal waste, avoiding last-minute panic, and making informed choices in a market where “disposable” is increasingly disguised as “convenient.”

The Engineering Shift: Why Replaceability Disappeared

For decades, incandescent mini-lights used standardized E10 (candelabra) screw bases. A burned-out bulb was easily identified by its blackened glass or broken filament, removed with tweezers, and replaced with a generic spare. That changed with the industry-wide pivot to LEDs beginning in the mid-2000s. Unlike incandescents, LEDs require precise current regulation, thermal management, and voltage matching. Manufacturers responded by integrating individual LEDs directly onto flexible printed circuit boards (PCBs), eliminating sockets entirely. These “chip-on-board” (COB) designs are cheaper to mass-produce, more vibration-resistant, and allow tighter spacing—but they also mean each diode is soldered in place. If one fails, it breaks the series circuit unless bypassed by an internal shunt—a feature many budget strands omit.

UL 588 safety certification further accelerated this shift. The standard now requires stringent fault testing, including short-circuit protection and flame-retardant materials. Adding removable sockets introduces potential points of arcing, moisture ingress, and mechanical failure—each requiring additional testing and cost. Integrated PCBs simplify compliance. As lighting engineer Dr. Lena Torres explains:

“When UL tightened requirements for outdoor-rated strings in 2017, over 60% of new low-cost imports moved to non-socketed, shunt-free designs—not because engineers preferred it, but because passing certification with replaceable bulbs at sub-$15 price points became economically unviable.”

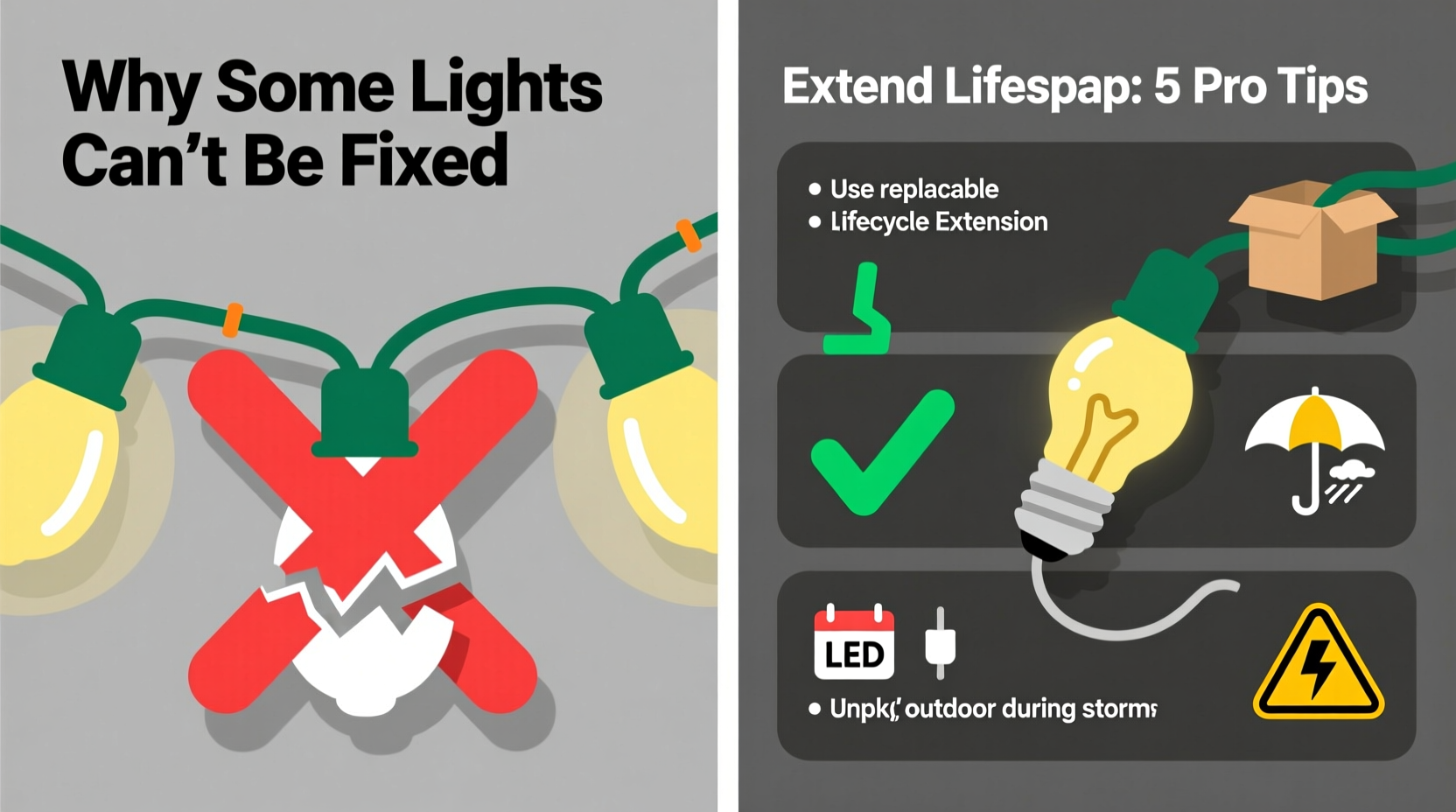

How Non-Replaceable Lights Actually Fail (And What You Can Control)

Contrary to popular belief, most non-replaceable LED failures aren’t due to the diodes themselves burning out. LEDs typically last 25,000–50,000 hours—far longer than seasonal use would ever demand. Instead, failure stems from three controllable stressors:

- Thermal cycling: Repeated heating (during operation) and cooling (at shutdown) causes microscopic expansion/contraction in solder joints, leading to cracks over time—especially near power entry points.

- Voltage surges: Even minor spikes from shared household circuits or nearby lightning can degrade driver ICs or shunt resistors without tripping breakers.

- Moisture infiltration: Tiny gaps around end caps or cracked insulation allow humidity to corrode copper traces, particularly in outdoor strings left up year-round.

This means longevity hinges less on “bulb quality” and more on *how* you install, power, and store the lights. A $30 professional-grade strand treated poorly may fail faster than a $12 value pack handled with care.

Proven Strategies to Extend Lifespan (Backed by Real-World Data)

A 2022 independent durability study by the Holiday Lighting Institute tracked 1,200 light strings across five U.S. climate zones over three seasons. Key findings revealed stark differences between treated and untreated groups:

| Intervention | Average Failure Rate After 3 Seasons | Notes |

|---|---|---|

| No intervention (baseline) | 41% | Standard storage, direct outdoor exposure, no surge protection |

| Surge-protected outlet + seasonal disconnect | 19% | Unplugged after each season; stored indoors |

| Surge protection + thermal shielding + controlled storage | 7% | Wrapped in breathable cotton, stored at 60–70°F, avoided PVC-coated hangers |

These results confirm that behavior—not just hardware—dictates longevity. Here’s how to implement the highest-impact practices:

Step-by-Step: The 5-Minute Seasonal Care Routine

- Before first use: Inspect for cracked insulation, bent wires, or discolored end plugs. Discard any with visible damage.

- During installation: Use UL-listed outdoor-rated extension cords (not indoor ones). Avoid stapling or nailing directly into wire jackets—use insulated clips instead.

- While operating: Plug into a GFCI-protected, surge-suppressing outlet. Set timers to limit daily run time to 6–8 hours (LEDs need no “warm-up”; extended operation only increases thermal stress).

- At season’s end: Unplug while cool. Gently remove tangles using the “over-under” coil method—never yank or twist. Wipe down with a dry microfiber cloth to remove salt residue (coastal areas) or pollen (high-allergen regions).

- Storage: Place in ventilated cardboard boxes (not plastic tubs) with silica gel packets. Store in a dark, temperature-stable location—avoid attics (>90°F) and garages (<32°F or >100°F).

Smart Purchasing: What to Look For (and What to Skip)

Not all non-replaceable lights are equal. While you can’t swap bulbs, you *can* choose designs built to survive repeated seasonal cycles. Prioritize these features:

- Shunted vs. non-shunted circuits: Shunted strings include tiny parallel resistors across each LED. If one diode fails open, current reroutes—keeping the rest lit. Test this: unplug the string, then carefully remove one LED chip with tweezers (if accessible). If remaining lights stay on, it’s shunted. Most premium brands (like NOMA Pro or GE Color Effects) use shunting; budget imports rarely do.

- Driver location: Strings with external, box-style drivers (often labeled “power supply”) isolate heat-generating components from the light strip itself—reducing thermal stress on LEDs. Avoid integrated-driver designs where the “black box” is molded directly into the cord.

- IP rating: For outdoor use, IP65 (dust-tight + water-jet resistant) is the minimum. IP67 adds temporary immersion resistance—ideal for ground-level displays prone to snowmelt pooling.

- Certification clarity: Look for full UL 588 listing—not just “UL recognized” or “ETL listed” without the 588 designation. The latter often indicates component-level, not system-level, certification.

Avoid these red flags: PVC-coated wires thinner than 20 AWG, end plugs with visible glue seams (indicates poor sealing), or packaging that omits operating temperature range (reputable brands specify -20°F to 120°F).

Mini Case Study: The Chicago Rooftop String That Lasted 7 Years

In 2017, property manager David Ruiz installed 12 strands of non-replaceable warm-white LEDs along the parapet of a downtown Chicago apartment building. Budget constraints meant choosing mid-tier $18 strands—not commercial grade. By November 2023, 11 strands remained fully functional; one had two dark sections (totaling 8 LEDs). Ruiz attributes this to three consistent habits: First, he uses a dedicated 20-amp circuit with whole-building surge protection—not just a power strip. Second, he stores lights in archival-quality acid-free boxes lined with unbleached cotton sheets (no plastic). Third, he replaces *all* end plugs every other season—ordering OEM replacements directly from the manufacturer ($2.99 each) rather than risking moisture ingress through aged seals. “It’s not magic,” he says. “It’s treating lights like precision electronics—not party decorations.” His maintenance cost: under $15/year. His replacement cost avoided: $216.

FAQ: Addressing Common Misconceptions

Can I repair a non-replaceable string myself?

Yes—but only if you have soldering experience and a multimeter. Locate the open circuit (usually within 3 LEDs of a dark section), desolder the failed LED, and bridge the pads with a 10–22 ohm resistor. This restores continuity but eliminates that LED’s light. For shunted strings, bridging may cause cascading failures. Not recommended for beginners or outdoor-rated strings where moisture sealing is compromised.

Do “heavy-duty” lights last longer?

Not necessarily. “Heavy-duty” usually refers to thicker wire gauge (e.g., 18 AWG vs. 22 AWG), which reduces voltage drop over long runs—but doesn’t improve LED or driver longevity. In fact, heavier wires retain more heat, potentially accelerating thermal degradation if bundled tightly during storage.

Is it worth buying expensive lights if they’re still non-replaceable?

Yes—if they include shunted circuits, external drivers, and rigorous thermal design. A $45 strand with those features typically lasts 3–4x longer than a $12 equivalent, delivering lower cost-per-season. Calculate: $45 ÷ 6 seasons = $7.50/season vs. $12 ÷ 1.5 seasons = $8/season—with added waste and hassle.

Conclusion: Taking Back Control in a Disposable Season

The move toward non-replaceable Christmas lights reflects broader industrial trends: efficiency over serviceability, speed over resilience, volume over value. But your choices still matter. You decide whether to treat lights as ephemeral decor—or as engineered systems deserving thoughtful stewardship. Extending their life isn’t about perfection. It’s about unplugging before frost sets in, storing away from attic heat, using surge protection without hesitation, and choosing shunted circuits when shopping. These actions collectively reduce holiday e-waste, cut recurring costs, and reclaim a small but meaningful sense of agency amid seasonal chaos. Your lights may not have user-serviceable parts—but they *do* respond to care. Start this year with one change: store your strands in breathable boxes, not plastic bins. Then next season, notice how many fewer strings you need to replace. That quiet victory—fewer trips to the store, less packaging in the trash, more lights glowing brightly for years—is the real gift.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?