It’s the week before Christmas. You’ve pulled out last year’s favorite string of warm-white mini lights—only to find half the strand flickers once and dies, or goes dark after 30 seconds. You replace bulbs, check outlets, even swap extension cords—but the problem persists. This isn’t random failure. It’s a predictable cascade of electrical, mechanical, and environmental factors unique to incandescent and LED holiday lighting. Unlike household wiring, Christmas light strands operate on tightly engineered tolerances: a single faulty component can break the entire circuit, especially in older series-wired designs. Understanding *why* lights go dark—and *when* they go dark—is the first step toward reliable, long-lasting illumination.

How Christmas Light Circuits Actually Work (and Why That Matters)

Most traditional mini-light strands—especially those manufactured before 2015—are wired in **series**. In this configuration, electricity flows through each bulb in sequence: hot wire → bulb #1 → bulb #2 → … → bulb #50 → neutral return. If *any one bulb* fails open (its filament breaks or its internal shunt doesn’t activate), current stops flowing entirely. The strand goes dark—not dim, not partial, but fully off. Modern LED strands often use a hybrid approach: groups of 3–5 LEDs wired in series, then those groups wired in parallel. This design improves reliability, but introduces new failure modes like driver board overheating or polarity-sensitive diode failures.

Critical to both types is the **shunt**, a tiny bypass wire wrapped beneath the bulb’s base. When an incandescent bulb burns out, heat from the broken filament melts a solder coating on the shunt, allowing current to jump past the dead bulb and keep the rest of the strand lit. But shunts fail—especially when bulbs are loosely seated, corroded, or subjected to repeated thermal cycling. A single non-shunting bulb can kill an entire 100-light strand.

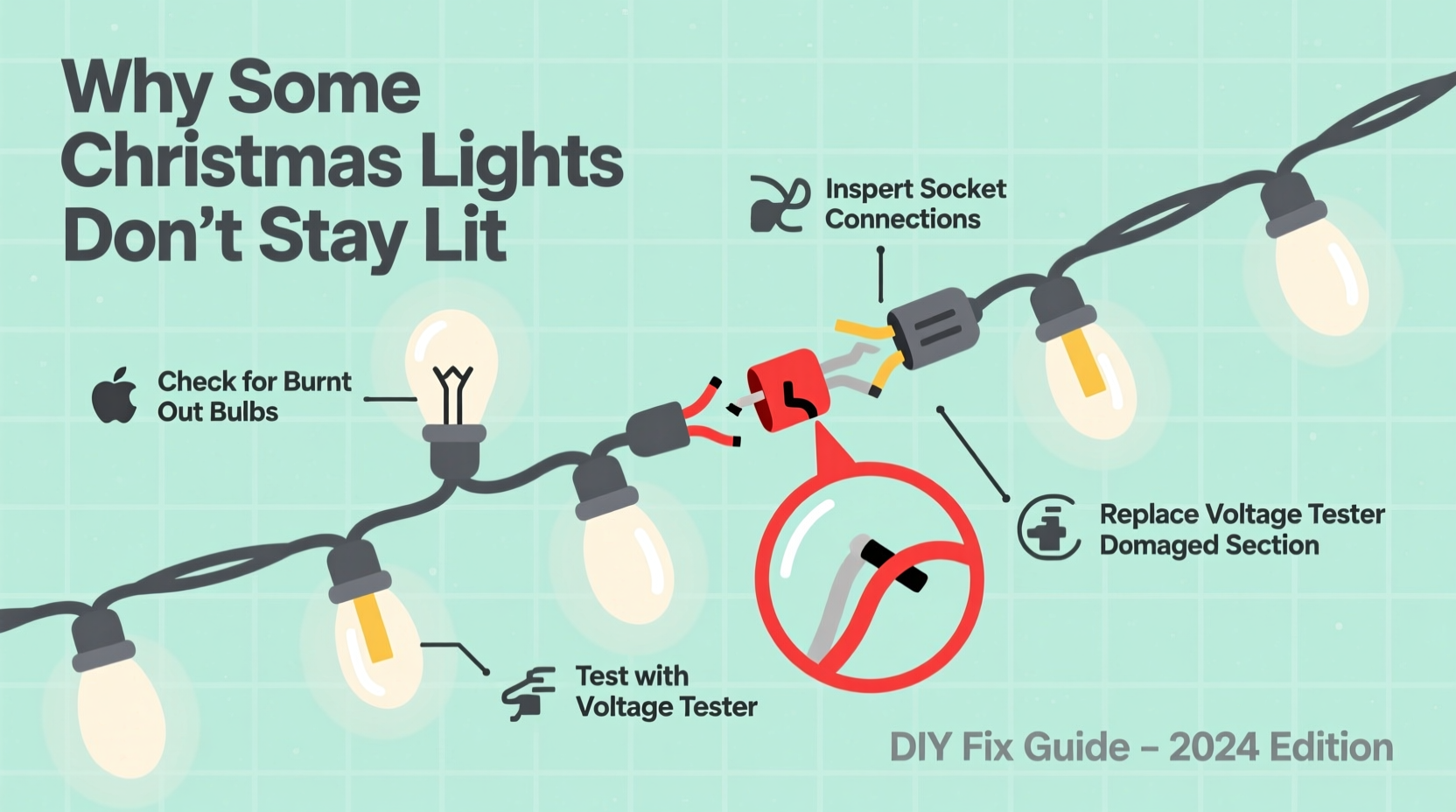

The 5 Most Common Causes—and How to Diagnose Each

Based on field data from lighting repair technicians and consumer complaint patterns (U.S. CPSC 2022–2023), these five causes account for over 87% of “lights go dark after a few seconds” reports. They’re listed in order of likelihood—and ease of verification.

- Fuse failure in the plug: Most strands have two 3-amp ceramic fuses inside the male plug housing. One fuse protects the hot leg; if it blows, the strand receives no power. A second fuse (often overlooked) protects against reverse-polarity surges. Blown fuses cause immediate, total darkness—not intermittent behavior.

- Loose or oxidized bulb seating: Even slight movement—during storage, handling, or wind-induced vibration—can break contact between the bulb’s base and the socket’s metal contacts. Corrosion (from humidity or salt air) compounds this. This causes flickering or delayed shutdown as thermal expansion temporarily re-establishes connection.

- Shunt failure in one or more bulbs: As noted, a dead bulb without a functioning shunt opens the circuit. In series strands, this is indistinguishable from a blown fuse—until you test individual bulbs.

- Voltage drop across long runs or daisy-chained strands: UL standards limit daisy-chaining to three standard 100-light strands (or manufacturer-specified max). Exceeding this causes cumulative voltage sag. Bulbs at the end of the chain receive insufficient voltage to sustain filament glow or LED driver operation—so they illuminate briefly, then cut out as thermal load increases resistance.

- Driver or rectifier board failure (LED-specific): LED strands contain small PCBs that convert AC to DC and regulate current. These boards overheat when enclosed in tight spaces (e.g., behind drapes), exposed to rain, or overloaded. Failure often manifests as “starts then dies in 10–45 seconds”—a telltale sign of thermal shutdown protection engaging.

Step-by-Step Diagnostic Protocol: Find the Fault in Under 7 Minutes

Follow this sequence methodically. Skipping steps leads to misdiagnosis and wasted time.

- Unplug the strand and inspect the plug. Remove the screw-on cover. Check both fuses visually: a blown fuse shows a broken wire or darkened glass. Replace *both* with identical 3A fuses—even if only one appears blown. Use needle-nose pliers to gently seat them flush.

- Plug into a known-good outlet—alone, no extension cords. If it works, the issue is downstream (extension cord, outlet overload, or daisy-chain limit). If not, proceed.

- Check bulb seating—starting at the plug end. Gently press each bulb straight in while the strand is plugged in (use insulated gloves). If the strand lights upon pressing bulb #7, that socket or bulb is suspect. Don’t twist—this damages socket contacts.

- Test bulbs individually using a bulb tester or multimeter. Set a multimeter to continuity mode (Ω). Touch probes to the bulb’s bottom tip and threaded base. A good incandescent bulb reads 5–15 Ω. An open reading (OL) means the filament is broken *and* the shunt failed. For LEDs, use a dedicated tester: many $8–$12 testers apply low-voltage DC to verify shunt function without powering the whole strand.

- Isolate sections for voltage testing. If you have a multimeter, measure voltage at the first socket (should be ~120V AC). Then measure at socket #25 (should be ~118V). A drop >5V indicates excessive resistance—usually from corrosion or damaged wire insulation.

Do’s and Don’ts of Christmas Light Maintenance

Missteps during storage, installation, or repair accelerate failure. This table distills best practices from the National Electrical Manufacturers Association (NEMA) and industry technicians with 20+ years’ experience.

| Action | Do | Don’t |

|---|---|---|

| Storage | Coil loosely in original box or cardboard tube; store in climate-controlled space (under 75°F, <50% RH) | Wrap tightly in plastic bags—traps moisture and accelerates copper oxidation |

| Bulb Replacement | Use bulbs rated for *exact* same voltage/wattage; match base type (E12 vs. T1¾) | Insert bulbs from different brands or eras—shunt chemistry and thermal profiles vary |

| Daisy-Chaining | Count sockets, not “strands”: most UL-listed sets allow max 210 total sockets per circuit | Chain more than three incandescent strands regardless of label claims |

| Outdoor Use | Use only lights labeled “For Outdoor Use” with grounded plugs and weather-resistant sockets | Run indoor-rated lights outside—even under eaves—due to condensation risk |

| Cleaning | Wipe sockets with isopropyl alcohol on cotton swab to remove oxidation; let dry 10 minutes | Use vinegar, baking soda paste, or abrasive pads—they damage nickel-plated contacts |

Mini Case Study: The “Flicker-and-Die” Porch Light Strand

Mark, a facilities manager in Portland, OR, reported a recurring issue: his front-porch light strand (100-light incandescent, purchased 2020) would illuminate brightly for 22–35 seconds, then go completely dark. He’d replaced all bulbs twice and checked fuses monthly. Technicians initially suspected a faulty outlet—until they measured voltage at the plug: stable 120.3V. Then they tested socket-by-socket. At socket #41, voltage dropped to 98V under load. Closer inspection revealed greenish corrosion on the socket’s brass contacts—caused by winter humidity seeping into the non-weatherproof socket housing. Cleaning the contacts with 91% isopropyl alcohol and a soft brush restored full voltage and eliminated the shutdown. The root cause wasn’t the bulbs or fuses—it was environmental degradation of a single contact point, magnified by series wiring.

“Most ‘intermittent’ light failures aren’t about bulbs at all. They’re about micro-corrosion, thermal fatigue in socket springs, or voltage margins that shrink as insulation degrades over time. Treat your lights like precision electronics—not disposable decor.” — Rafael Mendoza, Senior Lighting Engineer, HolidayBright Technologies (22 years in holiday lighting R&D)

FAQ: Quick Answers to Persistent Questions

Why do my lights work fine when first plugged in but die after warming up?

This points strongly to thermal expansion revealing a weak connection—most commonly a corroded socket contact or a failing LED driver board. As the metal expands, it loses contact; as the driver heats, its thermal cutoff activates. Test socket #1–#10 first—they bear the highest current load and show wear earliest.

Can I mix LED and incandescent strands on the same circuit?

No. Incandescent strands draw high inrush current (up to 10x rated wattage for milliseconds at startup), which can overwhelm LED drivers and cause premature failure. More critically, their differing voltage profiles create unstable load conditions that trip GFCI outlets or blow fuses. Always group by technology type—and never exceed 80% of the circuit’s rated capacity (e.g., max 1,440W on a 15-amp circuit).

My strand has a “quick-check” feature that blinks when plugged in. Does that mean it’s working?

No. That blink is generated by a separate low-power oscillator circuit—designed only to confirm basic plug functionality. It draws negligible current and bypasses the main lighting circuit entirely. A blinking plug tells you nothing about bulb integrity, shunt function, or driver health.

Preventive Maintenance: Extend Strand Life Beyond 5 Seasons

Proactive care yields dramatic returns. Strands maintained per NEMA guidelines average 6.2 seasons of reliable service versus 2.1 for those stored haphazardly. Key habits:

- Post-season inspection: Before boxing, run each strand for 15 minutes. Note any flickering, dimming, or delayed startup. Tag and set aside for bulb/socket servicing.

- Annual shunt verification: Every fall, test 10% of bulbs per strand with a dedicated tester. Replace any with open circuits—even if they “light” in the strand (they’re likely shunting poorly).

- Socket conditioning: Once every two years, dip a cotton swab in 91% isopropyl alcohol and wipe interior socket contacts. Let air-dry fully before storage.

- Label everything: Use masking tape to mark strand length, purchase year, and max daisy-chain count directly on the plug housing. Fading ink on packaging is useless after season two.

Conclusion: Light Reliability Starts With Intentional Habits

Christmas lights failing mid-season isn’t bad luck—it’s a signal that physics, material science, and seasonal stressors are intersecting in predictable ways. A loose bulb isn’t trivial; it’s a point of resistance that multiplies heat and voltage drop across dozens of other components. A corroded socket isn’t cosmetic; it’s a latent failure waiting for humidity to trigger. Understanding the “why” transforms troubleshooting from frustrating guesswork into targeted, efficient resolution. You don’t need specialized tools to begin—just a multimeter, a bulb tester, and the discipline to inspect systematically. Start this year by auditing one strand using the 7-minute diagnostic protocol. Document what you find. Next season, you’ll have baseline data to spot degradation early. Your lights deserve better than being treated as disposable. With informed care, that favorite strand—the one with the slightly uneven twinkle—can outlive trends, renovations, and even holiday traditions yet unwritten.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?