As the holiday season approaches, stringing up Christmas lights is a cherished tradition. But nothing dampens the festive spirit faster than discovering that only parts of your light strand illuminate. When entire sections go dark while others glow brightly, it’s more than an aesthetic issue—it’s a sign of an underlying electrical or physical problem. Unlike total failures, where no lights come on, section-specific outages point to localized faults such as broken bulbs, loose connections, or damaged wiring. Understanding how modern Christmas light circuits function—and what commonly causes partial failure—can save time, money, and frustration.

Most contemporary mini-light strands use a series circuit design, meaning electricity flows through each bulb in sequence. A single malfunction can disrupt current flow to downstream bulbs, causing entire segments to remain unlit. However, many newer sets include shunt wires within each bulb to bypass a failed filament, allowing the rest of the strand to stay lit. Despite this innovation, problems still arise due to manufacturing defects, environmental exposure, or wear from storage. This guide walks you through diagnosing and repairing non-working sections using practical, tested methods.

How Christmas Light Circuits Work: Series vs. Parallel

To effectively troubleshoot lighting issues, it’s essential to understand basic circuit types used in decorative lighting:

- Series Circuit: In traditional incandescent mini-lights, bulbs are wired end-to-end in a single path. Voltage is divided among all bulbs. If one bulb burns out or becomes dislodged, the circuit breaks and all subsequent bulbs go dark. Some designs incorporate shunts—small conductive coatings inside the bulb—that activate when the filament fails, rerouting current around the dead bulb.

- Parallel Circuit: Less common in standard strands but found in higher-end or LED sets. Each bulb has its own connection to the power source. Failure of one bulb doesn’t affect others. These are more reliable but often costlier.

- Sectional Design (Hybrid): Many modern strings divide into multiple parallel sections wired in series. For example, a 50-light strand might have five groups of ten bulbs. One failed bulb may kill only its group, leaving others functional.

This sectional behavior explains why you might see “half-lit” strands. The working portion indicates power is reaching the plug and initial segment; the dark zone suggests interruption after that point.

“Modern holiday lights are engineered for partial redundancy, but they’re only as strong as their weakest connection.” — Robert Linwood, Electrical Safety Engineer at Consumer Holiday Tech Labs

Common Causes of Sectional Failure

When part of a light strand refuses to turn on, several culprits could be responsible. Identifying them requires both visual inspection and systematic testing.

1. Burned-Out or Faulty Bulb

The most frequent cause. Even with shunted bulbs, a severely damaged or missing bulb can break continuity. Sometimes the shunt fails to activate due to corrosion or insufficient current surge during burnout.

2. Loose or Misaligned Bulb

If a bulb isn't fully seated in its socket, it creates a gap in the circuit. Vibration during handling or improper installation can cause this. Wiggling each bulb gently may restore contact.

3. Damaged Socket

Sockets can crack or warp over time, especially if stored under pressure or exposed to moisture. A compromised socket prevents proper electrical contact even with a good bulb installed.

4. Wire Break or Cut

Bending, pinching, or rodent activity can sever internal wires. Since many strands use fine-gauge copper, small nicks can interrupt current without visible external damage.

5. Poor Plug or Connector Contact

The male/female connectors between strands collect dirt and oxidize. Corrosion increases resistance and may prevent full voltage delivery, particularly affecting downstream sections.

6. Fuse Failure (Partial)

Some multi-section strands have individual fuses per segment. While rare in consumer-grade lights, premium outdoor sets may include fused sections. Check manufacturer specs if available.

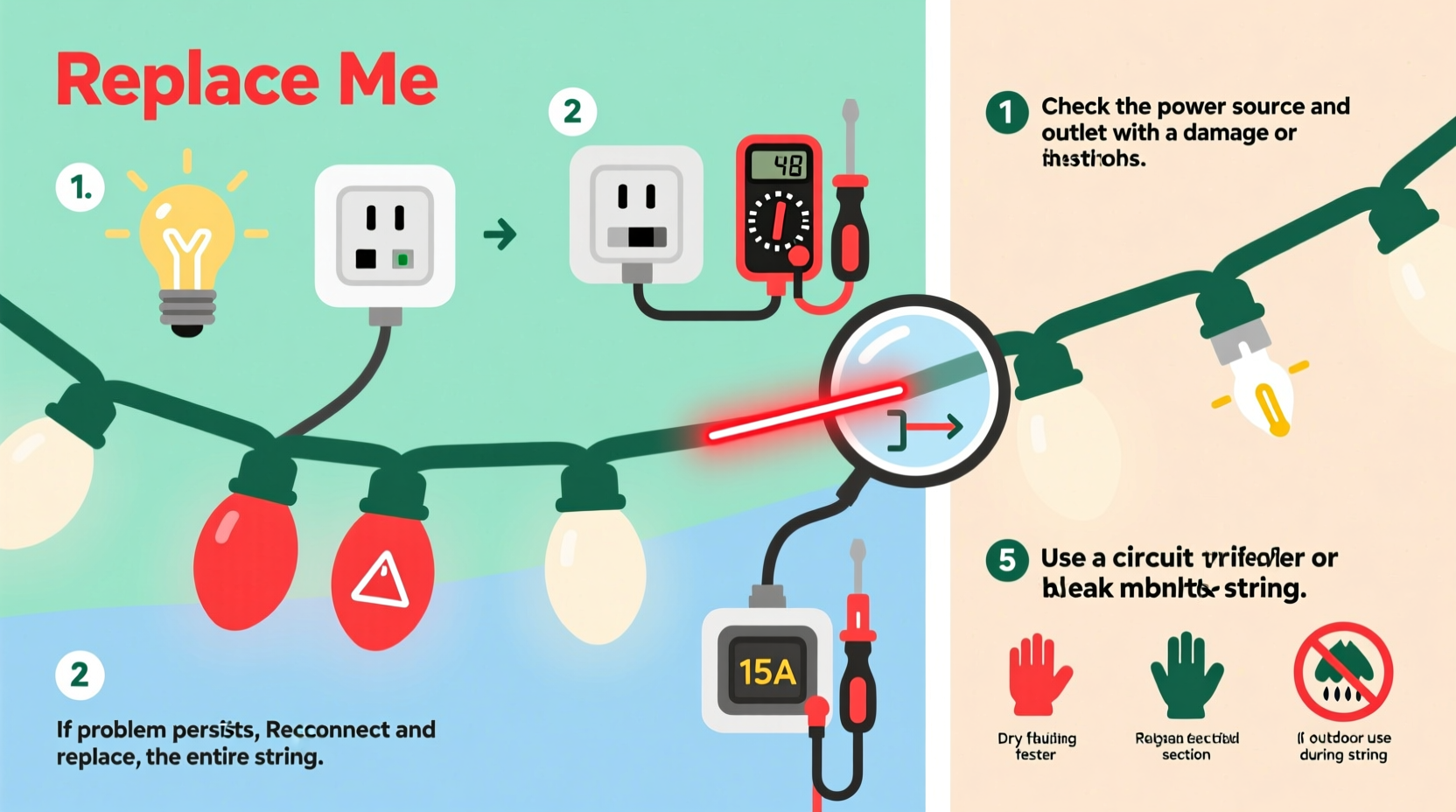

Step-by-Step Troubleshooting Process

Follow this logical progression to isolate and resolve the fault efficiently.

- Unplug the strand and examine the dark section visually. Look for obvious signs: missing bulbs, cracked sockets, kinked wires, or discoloration.

- Check all bulbs in the non-working section. Remove each one carefully and inspect the filament. Replace any with broken filaments—even if the glass appears intact.

- Test each removed bulb by inserting it into a known-working socket on another strand. Alternatively, use a multimeter set to continuity mode.

- Re-seat every bulb, including those that seem fine. Push firmly until you hear or feel a click, ensuring metal base contacts the socket terminals.

- Inspect connector ends. Clean metal prongs with isopropyl alcohol and a cotton swab. Reconnect securely and test again.

- Use a light tester tool (available at hardware stores) to scan along the wire. These detect live current and help pinpoint where voltage drops off.

- Examine for wire damage. Run fingers along the length near the transition point between working and dead sections. Feel for cuts, bulges, or soft spots indicating internal breakage.

- Check for shunt failure. In older incandescent sets, shake the suspect bulb slightly—if the filament rattles, it's likely broken and the shunt didn’t engage.

- Test with a replacement section. If possible, bypass the suspected bad segment with a jumper wire or substitute strand to confirm location of failure.

- Replace or rewire as needed. For permanent fixes, cut out damaged sections and splice in new wiring, or replace the entire strand if repair costs exceed replacement value.

Mini Case Study: The Porchlight Problem

A homeowner in Portland, Oregon, reported that every year, the lower third of her icicle lights failed shortly after setup. She replaced bulbs repeatedly but saw no lasting improvement. After consulting an electrician, she discovered the root cause: snowmelt dripping from the roof had soaked the lowest tier during previous winters, corroding sockets and degrading insulation. The repeated exposure caused intermittent shorts and eventual wire degradation. Her solution was twofold: elevate the bottom row slightly using insulated clips and apply dielectric grease to all connectors before installation. She also switched to commercial-grade LED strings rated for wet locations. Three seasons later, the lights continue functioning reliably.

Tips and Best Practices for Prevention

Preventing future issues starts with smarter usage and maintenance habits.

| Do | Don’t |

|---|---|

| Store lights coiled loosely around a cardboard reel or spool | Wrap tightly around sharp edges or staple wires to surfaces |

| Label strands by location and type (indoor/outdoor, voltage, color) | Mix different brands or voltages when connecting multiple strands |

| Clean plugs and connectors annually with alcohol wipes | Force connectors together if they don’t fit snugly |

| Use clips instead of nails or staples for mounting | Leave lights up year-round, especially in humid or snowy climates |

| Inspect before installation each season | Pull on wires to remove from gutters or trees |

LED vs. Incandescent: Which Is More Reliable?

LED Christmas lights have largely overtaken incandescent models due to energy efficiency and longevity. But how do they compare when it comes to sectional failures?

- LED Lights: Typically wired in series-parallel configurations. Individual LEDs rarely burn out, but driver circuits or resistors can fail, causing entire sections to go dark. They operate at low voltage and generate minimal heat, reducing fire risk and material stress.

- Incandescent Lights: Prone to filament breakage from vibration and thermal cycling. Higher heat output accelerates socket aging and insulation brittleness. However, their simpler design makes individual bulb replacement easier.

While LEDs last longer overall—often 25,000–50,000 hours compared to 2,000–3,000 for incandescents—they are less forgiving of voltage spikes and incompatible connections. Using an LED-rated extension cord and surge protector improves reliability.

Frequently Asked Questions

Can I connect LED and incandescent lights together?

No. Mixing types risks overloading circuits due to differing voltage and current requirements. LEDs usually draw less power, but combining them can confuse built-in regulators or cause flickering and premature failure.

Why do my new lights already have a dead section?

Manufacturing defects occur. Even reputable brands may ship faulty units. Inspect new strands immediately upon purchase and return defective ones promptly. Also verify correct insertion of end caps or terminators on non-continuous runs.

Is it worth fixing old light strands?

It depends. Repairing a high-quality commercial strand may be economical. But for inexpensive seasonal sets, replacement is often safer and more efficient. Consider safety: frayed wires, cracked insulation, or inconsistent brightness indicate retirement is due.

Essential Tools Checklist

Keep these items on hand for quick diagnostics and repairs:

- Replacement bulbs (same size, color, and voltage)

- Extra fuses (usually stored in the plug)

- Multimeter or dedicated light tester

- Needle-nose pliers and wire cutters

- Electrical tape or heat-shrink tubing

- Isopropyl alcohol and cotton swabs

- Digital camera or phone (to photograph complex setups before disassembly)

- Dielectric grease (for moisture protection on connectors)

Conclusion: Restore the Glow with Confidence

Sectional failures in Christmas lights are common but rarely insurmountable. With a clear understanding of circuit design, a methodical approach to diagnosis, and the right tools, most issues can be resolved in under an hour. Prioritize safety, invest in quality materials, and adopt preventive care routines to extend the life of your displays. Whether you're maintaining family heirloom strands or installing new smart-lit garlands, attention to detail ensures consistent performance year after year.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?