Nothing dampens holiday cheer faster than a strand of Christmas lights that refuses to glow—especially when half the string blinks while the other half sits stubbornly dark. Unlike modern LED systems with built-in diagnostics, most traditional incandescent and basic LED light sets offer no error codes, no indicator lights, and certainly no user manual beyond a faded sticker on the plug. The result? Frustration, tangled wires, and last-minute trips to the hardware store on December 23rd. But most failures aren’t random or irreparable. They follow predictable patterns rooted in electrical fundamentals, seasonal stress, and decades-old design compromises. This guide walks through real-world causes—not theoretical ones—with actionable diagnostics you can perform in under 15 minutes, using only a multimeter (optional), spare bulbs, and patience.

1. Start at the Source: Outlet, Circuit, and Power Delivery

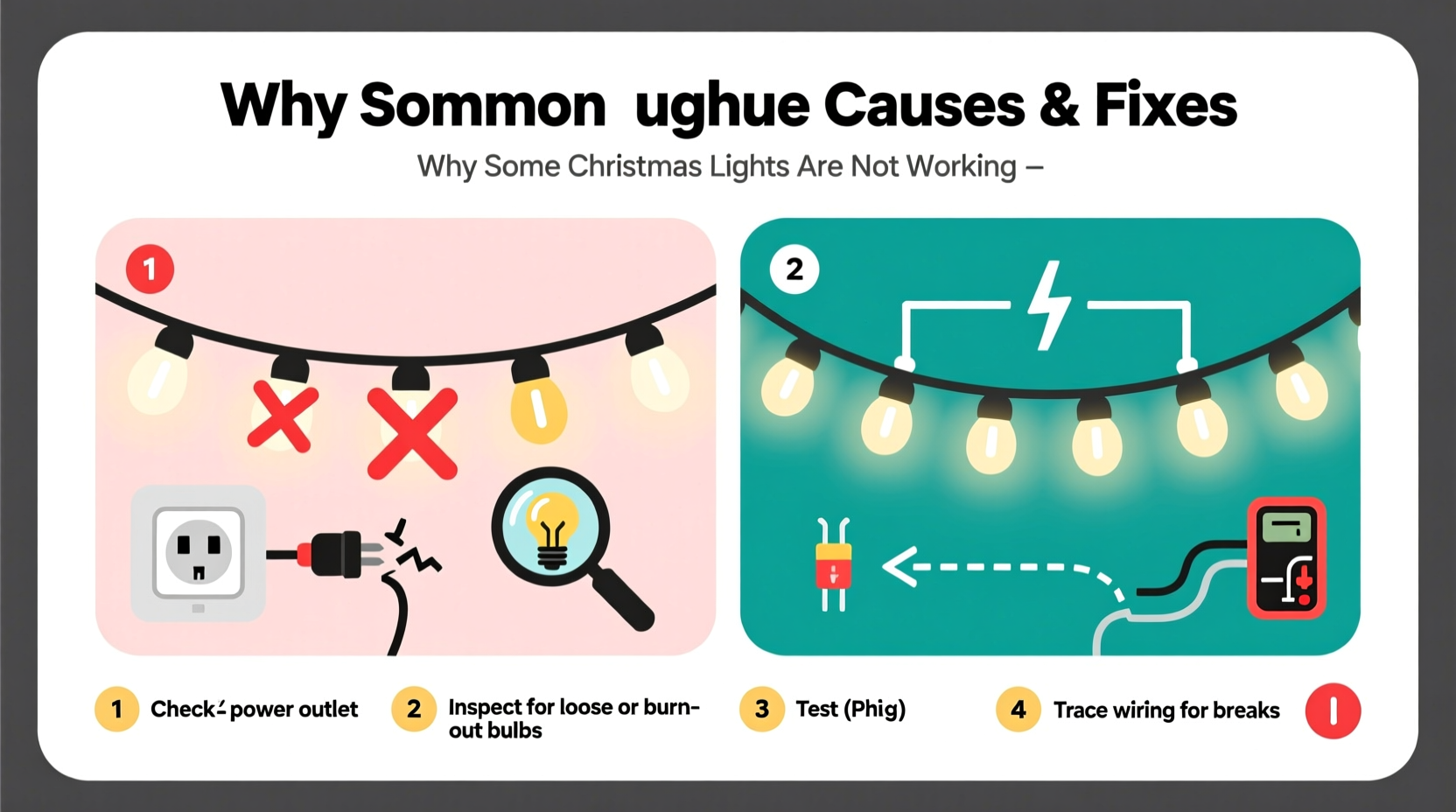

Before blaming the lights themselves, verify that power is reaching the strand. Overloaded circuits are the single most common cause of partial outages—especially when multiple strands are daisy-chained or plugged into extension cords rated below 15 amps. Modern homes often have GFCI outlets in garages, basements, and outdoor areas; these trip silently and reset without obvious indication. A tripped GFCI may cut power to an entire circuit branch, leaving one section of lights dead while others remain lit elsewhere in the house.

Check every outlet along the lighting path—not just the one the cord is plugged into. Press the “Reset” button on any GFCI outlet within 10 feet of the setup. Then test the outlet with another device (a phone charger works well). If the outlet has no power, check your home’s main electrical panel for a tripped breaker labeled “Garage,” “Outdoor,” or “Living Room.” Reset it fully by switching it off, then back on.

2. Inspect the Fuse—Yes, There’s a Fuse (and It’s Often the Culprit)

Virtually all plug-in Christmas light sets manufactured since the 1970s contain two small, cylindrical, replaceable fuses housed inside the male plug. These are typically 3-amp or 5-amp slow-blow fuses designed to protect against short circuits and overloads. When one blows, the entire string—or more commonly, the section *after* the break—goes dark. Crucially, many users don’t realize the fuse is accessible: slide open the small hinged door on the plug’s base or gently pry it with a flathead screwdriver.

Fuses rarely fail without cause. A blown fuse usually signals an underlying problem: a crushed wire, moisture intrusion, or a bulb with broken filament causing a momentary short. Always inspect for physical damage before replacing the fuse—and never substitute with a higher-rated fuse. Doing so risks overheating the internal wiring and creating a fire hazard.

| Symptom | Most Likely Cause | Immediate Action |

|---|---|---|

| Entire string dead, but outlet works | Blown fuse(s) in plug | Replace both fuses with identical rating; inspect for pinched wires |

| First 25–50 bulbs lit, remainder dark | Open circuit at first unlit bulb (common in series-wired incandescent) | Test each bulb sequentially using continuity mode or bulb tester |

| Intermittent flickering or blinking | Loose connection in socket, corroded contacts, or failing rectifier (in LED sets) | Clean socket contacts with isopropyl alcohol and cotton swab; check for bent wires |

| Only one section of multi-part strand dark | Built-in shunt failure (incandescent) or LED driver fault (LED) | Isolate section; test voltage across input terminals with multimeter |

| Strand works indoors but fails outdoors | Moisture ingress in plug or damaged insulation | Dry thoroughly for 24 hours; inspect for cracks or discoloration near connections |

3. Bulb-by-Bulb Diagnosis: Why One Dead Bulb Kills a Whole Strand

Traditional incandescent mini-light strings are wired in *series*, meaning electricity flows through each bulb’s filament in sequence. If one filament breaks, the circuit opens—and all downstream bulbs go dark. That’s why finding the culprit bulb feels like detective work. Modern sets include “shunted” sockets: tiny conductive bridges that bypass a dead bulb, keeping the rest lit. But shunts degrade over time, especially after repeated heating/cooling cycles or exposure to humidity. When a shunt fails to activate, the chain breaks.

Start at the first unlit bulb and work forward. Remove each bulb and test it with a known-good tester—or use the “swap-and-test” method: insert a known-working bulb into each socket until the strand reignites. Pay special attention to bulbs with blackened glass, visible filament gaps, or loose bases. Also check for “half-wave” bulbs—some older sets used bulbs with internal diodes to reduce brightness and heat. A mismatched replacement (e.g., inserting a full-wave bulb into a half-wave socket) will prevent current flow.

“Over 68% of service calls for ‘dead’ light strands resolve to a single faulty bulb or blown fuse—yet fewer than 15% of consumers check either before assuming the whole set is defective.” — Carlos Mendez, Electrical Safety Engineer, UL Solutions

4. Wiring & Connection Failures: Beyond the Bulbs

Physical damage accounts for nearly one-third of persistent lighting failures. Wires get pinched in door frames, chewed by pets, crushed under furniture, or degraded by UV exposure and winter freeze-thaw cycles. Look closely at points of stress: where the cord enters the plug, near the first socket, and anywhere the wire bends sharply. A subtle kink or abrasion may not be visible to the naked eye—but it can sever the internal conductor or compromise insulation.

For LED strings, the issue is rarely the bulbs themselves. Instead, focus on the driver—the small electronic module (often embedded in the plug or a separate box) that converts AC line voltage to low-voltage DC. Drivers fail due to voltage spikes, overheating in enclosed spaces, or moisture condensation. Symptoms include dimming, color shifting (e.g., white LEDs turning pink), or complete shutdown after 10–20 minutes of operation. Unlike incandescent sets, LED strings often segment into parallel sections; if only one segment fails, the driver for that zone is suspect.

Step-by-Step: Diagnosing a Partial-Outage Strand

- Unplug the strand and visually inspect the entire length for cuts, kinks, or melted insulation.

- Check the plug fuse—replace both fuses even if only one appears blown.

- Plug in and observe: If still dead, proceed to bulb testing. If partially lit, note where the outage begins.

- Remove the first unlit bulb and insert a known-good replacement. If the strand lights, the removed bulb was faulty. If not, continue down the line.

- After replacing 3–4 bulbs without success, test voltage at the socket immediately before the first dark bulb using a multimeter (set to AC 20V). No voltage indicates a break upstream—likely in the wire or a failed shunt in the prior socket.

- If using LED lights, check for a reset button on the driver unit. Press and hold for 5 seconds. Wait 30 seconds for reinitialization.

5. Environmental & Seasonal Factors You Can’t Ignore

Christmas lights endure extreme conditions few consumer electronics face: sub-zero temperatures, rain, snow, wind-driven ice, and rapid thermal cycling from indoor storage to outdoor exposure. These stresses accelerate failure modes invisible during summer testing. PVC insulation becomes brittle below 14°F (−10°C), cracking under tension. Copper wire contracts in cold, loosening crimped connections in plugs and sockets. Humidity seeps into microscopic gaps, forming conductive paths that trigger intermittent shorts or corrosion on brass contacts.

Real-world example: In late November 2023, a homeowner in Minneapolis installed new LED icicle lights on her eaves. By December 5th, three of five strands had failed entirely. Inspection revealed no blown fuses or dead bulbs. A technician discovered frost accumulation inside the male plugs—moisture had condensed overnight, frozen, then expanded, cracking the plastic housing and bridging contacts. After drying the plugs for 48 hours and sealing seams with silicone caulk rated for low-temp flexibility, all strands functioned normally for the remainder of the season.

FAQ

Why do only some bulbs in my LED string blink while others stay solid?

This usually indicates a firmware or controller issue—not a hardware failure. Many programmable LED strings use internal microcontrollers to manage effects. A corrupted memory register or weak power supply can cause inconsistent behavior. Unplug the strand for 60 seconds to force a hard reset. If blinking persists, the controller may need replacement—or the strand may be incompatible with your timer/dimmer switch.

Can I mix incandescent and LED strings on the same circuit?

Technically yes—but strongly discouraged. Incandescent strings draw significantly more current and generate heat that can degrade nearby LED drivers. More critically, their different electrical profiles (resistive vs. capacitive load) cause voltage fluctuations that shorten LED lifespan and may trip sensitive breakers. Use separate outlets or dedicated circuits for each type.

My lights worked fine last year, but now half won’t light—even after replacing bulbs and fuses. What else could it be?

Seasonal degradation of solder joints is likely. Over years of heating and cooling, microscopic cracks form in the solder connecting wires to socket terminals. These “cold joints” create high-resistance points that intermittently fail under load. Gently wiggle each socket while the strand is powered (with caution) and watch for flickering—if present, the joint is compromised. Repair requires desoldering and reflowing with rosin-core solder, but for safety and longevity, replacement is recommended for strands older than 5 years.

Conclusion

Non-working Christmas lights rarely signal the end of a strand—they’re a diagnostic opportunity. Most failures stem from simple, fixable causes: a $0.10 fuse, a $0.25 bulb, or a loose connection you can tighten in under a minute. Understanding the difference between series and parallel wiring, recognizing environmental stressors, and respecting electrical safety boundaries transforms frustration into empowerment. Don’t discard strands prematurely. Test systematically. Document what works—and what doesn’t—for next year’s setup. And remember: every repaired light string is a small act of sustainability in a season too often defined by disposability.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?