In a world built on curves, symmetry, and complex forms, one shape stands out for its unmatched structural integrity: the triangle. From ancient pyramids to modern suspension bridges, the triangle is the backbone of strength in design. Unlike squares or rectangles, which can deform under pressure, triangles resist change. Their geometry inherently distributes force efficiently, making them indispensable in engineering, architecture, and even biology. But what exactly makes this three-sided figure so powerful? The answer lies in both mathematics and real-world application.

The Geometry of Strength

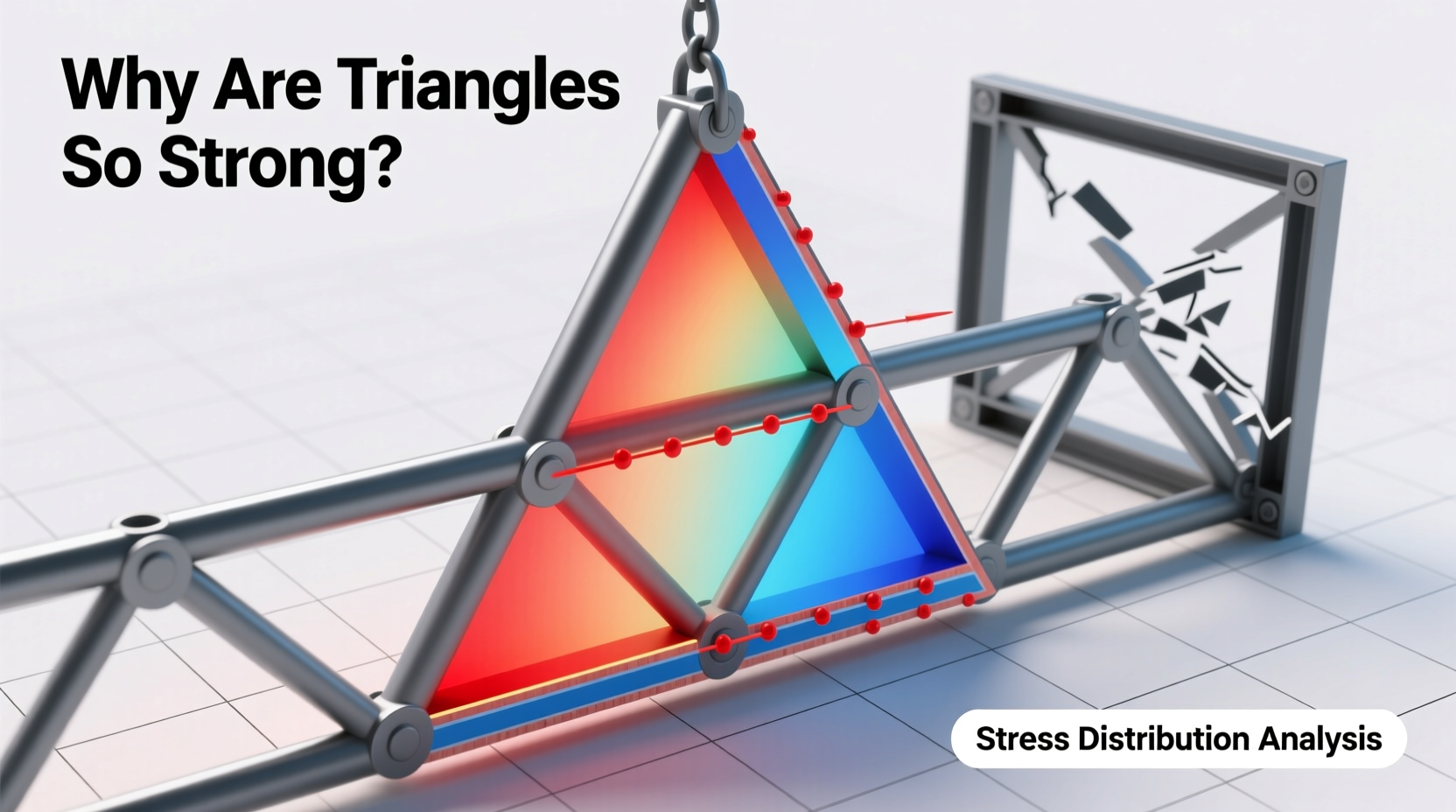

The triangle is the simplest polygon in Euclidean geometry, composed of three sides and three angles. Its strength begins with rigidity—a defining trait that sets it apart from other shapes. When force is applied to any vertex or side of a triangle, the load is evenly distributed across the other two sides. This happens because the angles in a triangle are fixed once the side lengths are set. You cannot alter one angle without changing the length of at least one side, which makes deformation nearly impossible without breaking the structure.

In contrast, quadrilaterals like squares or rectangles lack this intrinsic rigidity. Push on one corner of a square frame, and it can easily collapse into a parallelogram unless reinforced. Engineers often stabilize such frames by adding diagonal braces—effectively turning a square into two triangles. This principle is used universally in construction to prevent lateral movement and buckling.

“Of all geometric forms, the triangle is uniquely stable. It’s not just strong—it’s predictably strong.” — Dr. Alan Pierce, Structural Engineer and Professor at MIT

Force Distribution and Load-Bearing Efficiency

Triangles excel at managing two types of mechanical stress: compression (pushing forces) and tension (pulling forces). In truss systems—commonly seen in bridges and roofs—triangular units transfer loads from one point to another through these forces. Each member of the triangle either resists being pushed together (compression) or pulled apart (tension), minimizing bending moments that could lead to failure.

Consider a simple roof truss. The peak of the triangle bears the downward weight of snow or materials. This load pushes down on the top joint, which then transfers the force along the sloped sides into compression. At the base, the horizontal tie beam resists outward spreading, placing it under tension. Because each component handles a specific type of stress, the entire system remains balanced and durable.

Real-World Applications of Triangular Stability

The principles of triangular strength are visible everywhere—from microscopic molecular structures to massive skyscrapers. Here are some key domains where triangles make a critical difference:

- Bridges: Truss bridges use interlocking triangles to span long distances without intermediate supports. The Warren and Pratt truss designs rely entirely on triangular geometry for load distribution.

- Towers: Radio masts and transmission towers are built as triangular lattice structures to withstand wind and gravitational forces.

- Architecture: Geodesic domes, popularized by Buckminster Fuller, consist of interconnected triangles that create spherical strength using minimal materials.

- Aerospace: Aircraft wings and fuselage frameworks incorporate triangular bracing to maintain shape during flight stresses.

- Nature: Carbon atoms in diamond form tetrahedral (three-dimensional triangle-based) lattices, contributing to its status as one of the hardest natural substances.

Mini Case Study: The Eiffel Tower

No discussion of triangular strength would be complete without mentioning the Eiffel Tower. Designed by Gustave Eiffel for the 1889 World's Fair, the tower rises over 300 meters using an open iron lattice composed almost entirely of triangles. Despite its height and exposure to high winds, the structure remains remarkably stable. Wind flows through the open framework, and the triangular cells distribute aerodynamic forces evenly. During construction, critics feared it would collapse, but the intelligent use of triangular rigidity proved them wrong. Over 130 years later, it still stands as a testament to geometric efficiency.

Why Other Shapes Fall Short

To fully appreciate the triangle’s superiority, compare it to other polygons under stress. A square, for example, has four degrees of freedom when subjected to lateral force—its corners can shift unless constrained. Adding a diagonal brace creates two triangles, locking the angles and eliminating instability. Similarly, pentagons and hexagons may appear strong but require internal triangulation to maintain shape under load.

This concept extends into three dimensions. While cubes can buckle under pressure, tetrahedrons (the 3D equivalent of triangles) are inherently rigid. That’s why space frames and modular buildings often use tetrahedral modules—they provide maximum stability with minimal mass.

| Shape | Rigidity | Load Distribution | Common Reinforcement Method |

|---|---|---|---|

| Square | Low (without bracing) | Poor – prone to shear | Diagonal brace (creates triangles) |

| Triangle | High – naturally rigid | Excellent – self-distributing | None needed |

| Hexagon | Moderate | Good in compression | Internal triangulation |

| Tetrahedron | Very High | Optimal in 3D space | Self-supporting |

Building with Triangles: A Step-by-Step Guide

Whether you're a student, hobbyist, or aspiring engineer, applying triangular principles in small-scale projects builds intuition for structural design. Follow this process to create a strong model bridge or tower:

- Choose your material: Balsa wood, popsicle sticks, or straws work well for prototypes.

- Design the base: Start with a triangular footprint for maximum stability.

- Create trusses: Use equilateral or isosceles triangles for uniform force distribution.

- Join connections securely: Glue or tape joints thoroughly—weak points often occur at vertices.

- Test gradually: Apply weight slowly to observe how forces travel through the structure.

- Analyze failure points: If a section bends, reinforce it with additional triangular bracing.

Frequently Asked Questions

Can any triangle be strong, or do the angles matter?

All triangles are structurally rigid, but certain configurations perform better under specific loads. Equilateral triangles distribute force most evenly. Right triangles are practical for construction due to perpendicular alignment. Very narrow or obtuse triangles may concentrate stress at acute angles, increasing risk of material failure at joints.

Why don’t we build everything using triangles?

While triangles are strong, they aren’t always practical for space utilization. Rooms with triangular walls waste floor space and complicate furniture placement. Additionally, manufacturing curved or aesthetic designs with triangles requires more components. They’re ideal for frameworks, but less so for finished surfaces or living spaces.

Are triangles used in earthquake-resistant buildings?

Yes. Seismic engineering often incorporates triangular bracing in the form of shear walls or diagonal crossbeams. These elements help buildings resist lateral shaking by channeling energy through rigid, predictable paths. Steel frames with triangular infill are common in high-risk zones.

Checklist: Designing with Triangular Strength

- ✅ Identify load-bearing points in your structure

- ✅ Replace rectangular frames with triangular bracing

- ✅ Use strong materials at connection points (joints)

- ✅ Prioritize equilateral or right-triangle configurations

- ✅ Test prototypes under realistic stress conditions

- ✅ Minimize bending members—favor tension and compression

Conclusion

The strength of the triangle isn’t magic—it’s mathematics made visible. Its ability to maintain shape, distribute forces, and resist deformation makes it the foundation of resilient design across disciplines. From the pyramids of Giza to the International Space Station, humanity’s greatest structures rely on this simple, unshakable form. Understanding why triangles are so strong empowers us to build smarter, lighter, and safer environments. Next time you see a bridge, a roof, or even a bicycle frame, look closely—you’ll likely find triangles doing the heavy lifting.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?