When a strip of metal curves in response to heat or cold without any external force, it may seem like magic—but the science behind it is both elegant and practical. This phenomenon is most clearly seen in bimetallic strips, commonly found in thermostats, thermometers, and industrial sensors. The bending occurs due to differences in how two bonded metals expand or contract when exposed to temperature fluctuations. Understanding this behavior reveals not only fundamental principles of materials science but also enables precise control in everyday devices.

The Science Behind Thermal Expansion

All solids expand when heated and contract when cooled—a principle known as thermal expansion. As temperature increases, atoms within a material vibrate more intensely, pushing neighboring atoms slightly farther apart. Over millions of atoms, this results in measurable dimensional changes across the object.

Different metals expand at different rates. This variation is quantified by the coefficient of linear thermal expansion (α), which measures how much a material’s length changes per degree of temperature rise. For example:

| Metal | Thermal Expansion Coefficient (per °C) |

|---|---|

| Invar (Iron-Nickel alloy) | ~0.6 × 10⁻⁶ |

| Steel | 12 × 10⁻⁶ |

| Copper | 17 × 10⁻⁶ |

| Aluminum | 23 × 10⁻⁶ |

| Zinc | 30 × 10⁻⁶ |

The greater the value of α, the more a metal expands for each degree of temperature increase. When two metals with significantly different expansion coefficients are bonded together, their unequal responses to heat create internal stress—and visible bending.

How Bimetallic Strips Work: A Closer Look

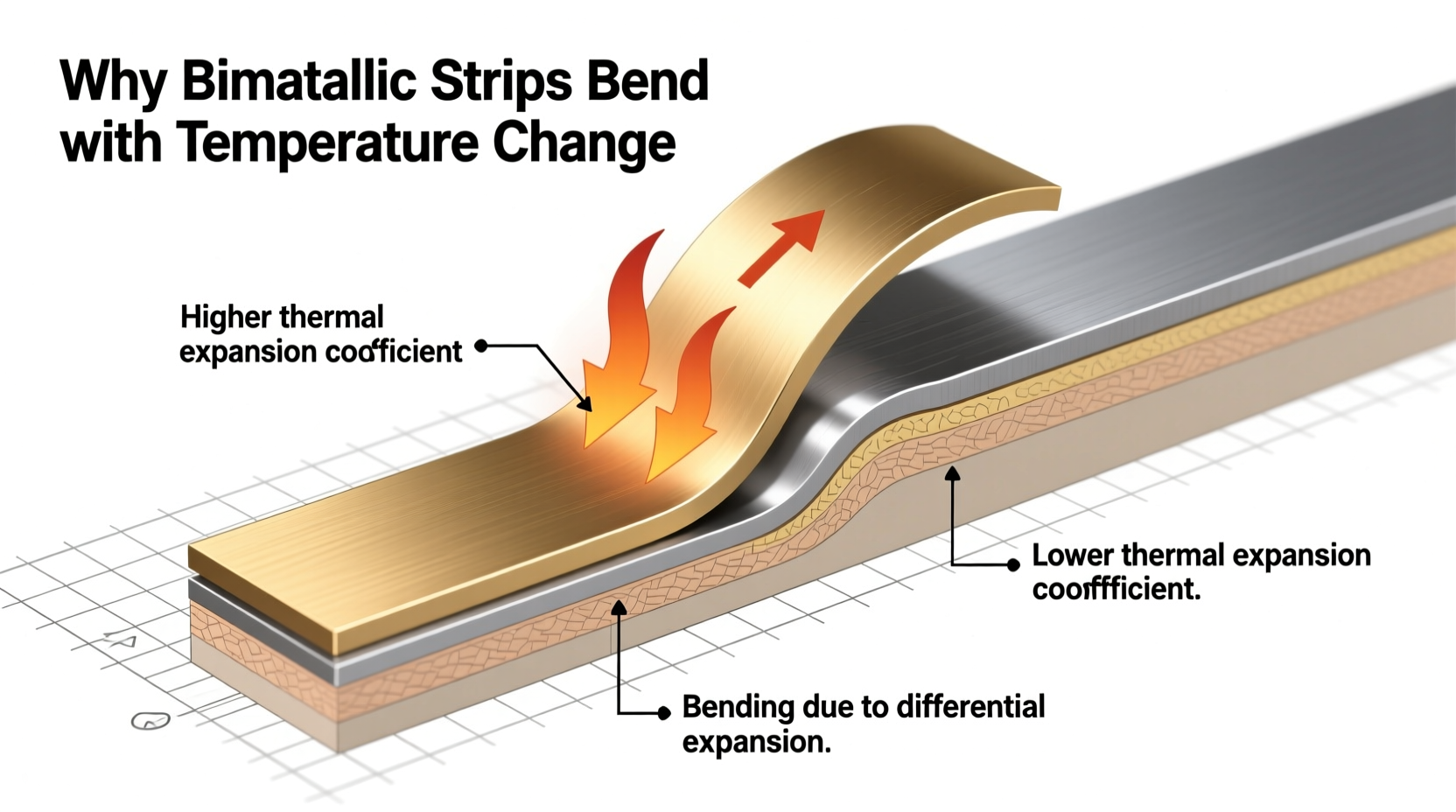

A bimetallic strip consists of two thin strips of different metals laminated together along their entire length. Common pairings include brass and steel, or copper and iron—combinations where one metal expands much more than the other.

When the strip is heated:

- The metal with the higher expansion coefficient (e.g., brass) elongates more.

- The metal with lower expansion (e.g., steel) resists stretching.

- Because they are firmly bonded, the faster-expanding metal cannot simply stretch freely—it instead forces the whole strip to curve toward the side of the slower-expanding metal.

Cooling produces the opposite effect: the higher-expansion metal contracts more, pulling the strip into a curve in the reverse direction.

“Bimetallic action turns invisible temperature shifts into mechanical motion—making it one of the simplest yet most effective transduction mechanisms in engineering.” — Dr. Rajiv Mehta, Materials Physicist, MIT

Direction of Bending: Predictable and Controllable

The direction of curvature depends on which metal is on which side. If the high-expansion metal is on top, heating causes upward bending; if on the bottom, it bends downward. Engineers design the orientation based on how the movement will interact with switches or dials in a device.

Real-World Application: The Thermostat Case Study

One of the most widespread uses of bimetallic strips is in household thermostats. Consider a traditional wall-mounted thermostat used to regulate furnace operation:

In a typical setup, a coiled bimetallic strip connects to an electrical switch. As room temperature rises, the coil slowly unwinds due to differential expansion. Once it reaches a preset point, the motion breaks contact with the circuit, turning off the heater. When the room cools, the coil tightens again, re-establishing the connection and restarting the system.

This self-regulating mechanism requires no external power for sensing—only electricity to operate the switch. It's reliable, durable, and functions effectively for years with minimal maintenance.

Industrial ovens, refrigerators, and even some older car temperature gauges use similar designs. Their longevity stems from the simplicity and robustness of the bimetallic principle.

Step-by-Step: How Temperature Triggers Mechanical Response

Here’s a breakdown of the physical process that transforms heat into motion within a bimetallic strip:

- Temperature Change Occurs: Ambient temperature increases or decreases around the strip.

- Differential Expansion Begins: One metal layer starts expanding (or contracting) more rapidly than the other.

- Internal Stress Builds: Since the layers are bonded, shear stress develops at the interface.

- Bending Initiates: To relieve stress, the strip curves toward the side of the less reactive metal.

- Mechanical Action Takes Place: The tip of the strip moves enough to open or close an electrical contact, adjust a pointer, or trigger a valve.

- Equilibrium Reached: Movement stops once thermal equilibrium is achieved or the device resets.

This sequence repeats continuously in cycling systems like HVAC units, providing passive feedback control rooted in basic physics.

Design Considerations and Optimization

While the concept is simple, effective implementation requires careful engineering. Key factors include:

- Choice of Metals: Must have sufficiently different expansion coefficients while maintaining strong adhesion and resistance to fatigue.

- Strip Thickness: Thinner strips respond faster but are more fragile; thicker ones are durable but slower.

- Bonding Quality: Poor lamination leads to delamination over time, especially under repeated thermal cycling.

- Shape Configuration: Straight strips offer limited travel; coiled versions amplify small movements for greater sensitivity.

Manufacturers often pre-age strips through controlled heating cycles to stabilize performance before deployment.

Do’s and Don’ts in Bimetallic Strip Applications

| Do | Don't |

|---|---|

| Select metals with large Δα values for better sensitivity | Use metals prone to oxidation at bonding surfaces |

| Protect strips from moisture and corrosive environments | Expose them to sudden thermal shocks beyond rated range |

| Use coiled designs for compact, high-movement applications | Allow excessive mechanical loading that could deform the strip permanently |

Frequently Asked Questions

Can a bimetallic strip work below freezing temperatures?

Yes. Bimetallic strips function across a wide temperature range, including sub-zero conditions. However, extremely low temperatures may reduce ductility, increasing the risk of cracking. Special alloys like Invar-based combinations are used in cryogenic applications.

Why doesn’t the strip return exactly to its original position after heating?

Slight hysteresis can occur due to residual stresses or micro-deformations after repeated bending. High-quality strips minimize this through annealing and precision manufacturing, but minor lag is normal in analog systems.

Are bimetallic strips still relevant in the age of digital sensors?

Absolutely. While digital thermistors and RTDs offer higher accuracy, bimetallic strips remain vital where reliability, cost-effectiveness, and fail-safe mechanical operation matter—such as safety cut-offs, backup controls, and consumer appliances.

Maximizing Longevity and Performance: Practical Checklist

To get the most out of bimetallic components in your projects or devices, follow this checklist:

- ✔ Choose appropriate metal pairs based on operating temperature range

- ✔ Ensure clean, oxide-free bonding surfaces during fabrication

- ✔ Shield the strip from vibration and mechanical shock

- ✔ Avoid exposure to chemicals that could corrode either metal layer

- ✔ Calibrate regularly in critical applications to account for aging effects

- ✔ Use protective housings with adequate airflow for consistent thermal response

Conclusion: Harnessing Physics for Everyday Control

The bending of bimetallic strips with temperature change is a perfect example of how fundamental physical laws enable practical technology. From keeping homes warm to protecting machinery from overheating, these simple yet intelligent devices convert thermal energy into reliable mechanical action—without batteries, software, or complex circuitry.

By understanding the interplay between material properties and temperature, engineers continue to refine and apply this century-old innovation in new contexts. Whether you're designing a product, repairing an appliance, or simply curious about how things work, appreciating the science behind bimetallic behavior opens a window into the quiet elegance of engineered solutions.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?