It’s a familiar holiday frustration: you’ve spent hours arranging your cherished Christmas village—hand-painted cottages, glowing streetlamps, miniature trains—only to have it go completely dark the moment you plug in a fresh string of LED icicle lights or a new animated display. No flicker. No hum. Just silence—and a growing sense of seasonal panic. This isn’t just bad luck. It’s almost always a symptom of an underlying electrical mismatch or safety response that modern village systems are engineered to detect. Unlike simple incandescent light strings from decades past, today’s villages integrate microcontrollers, low-voltage transformers, and sensitive timing circuits—all vulnerable to subtle power disruptions introduced by incompatible accessories.

The good news? In over 85% of cases like this, the issue is reversible, non-destructive, and rooted in predictable physics—not faulty craftsmanship or irreversible damage. What appears to be “broken” is often the system doing exactly what it was designed to do: protecting itself from overload, short circuits, or grounding anomalies. Understanding why requires looking beyond the outlet and into how vintage-style villages interact with contemporary lighting technology.

How Christmas Villages Actually Receive Power (and Why It’s Fragile)

Most traditional Christmas villages—including brands like Department 56, Lemax, and Bachmann—do not run on standard 120V household current. Instead, they rely on low-voltage AC or DC power supplied through proprietary transformers or plug-in adapters. Common configurations include:

- 12–24V AC transformers (often rated 30–60VA), used for older analog villages with synchronized lighting sequences;

- 5V or 9V DC regulated adapters, increasingly common in newer villages with micro-LEDs, sound modules, or Bluetooth connectivity;

- Multi-output hubs that split one transformer across several zones (e.g., main square, train loop, snowfall effect), each with independent current limits.

Crucially, these systems operate near their maximum design capacity—even before adding external lights. A typical 30VA transformer can supply ~2.5 amps at 12V. That sounds generous until you calculate real-world draw: a single animated chimney effect may pull 350mA, a flickering fireplace 420mA, and a rotating carousel 600mA. Add three 12V LED light strings (each drawing 180–220mA), and you’re at 95%+ load—well within thermal tolerance but dangerously close to triggering protective cutoffs.

The Top 5 Electrical Conflicts Caused by New Lights

Plugging in new lights doesn’t just add wattage—it introduces new electrical behaviors that legacy village electronics weren’t built to handle. Here’s what’s likely happening under the hood:

- Voltage Drop Under Load: Long runs of thin-gauge wire (common in pre-wired village bases) experience resistance. When new lights activate, voltage at the farthest cottage may dip from 12.0V to 10.3V—below the minimum threshold for microcontroller operation. The result? A full system shutdown or intermittent resets.

- Ground Loop Interference: Many new LED strings use switched-mode power supplies (SMPS) that reference neutral differently than village transformers. When both share the same outlet or power strip, small potential differences create circulating currents—disrupting signal timing and causing flickering or complete blackouts.

- Inrush Current Surge: LED strings with capacitive filtering can draw 5–7x their rated current for 20–100 milliseconds at startup. Village controllers interpret this as a short circuit and shut down immediately—even if the surge lasts less than a blink.

- DC Ripple Contamination: Cheap AC-to-DC adapters for new lights often output “noisy” DC with high AC ripple (10–25%). When coupled with a village’s sensitive analog dimming circuits, this noise mimics signal corruption—causing erratic behavior or silent failure.

- Polarity Reversal (DC Systems Only): If your village uses a barrel-plug DC adapter, reversing polarity—even once—can instantly damage protection diodes or voltage regulators. New lights with mismatched plugs increase accidental reversal risk.

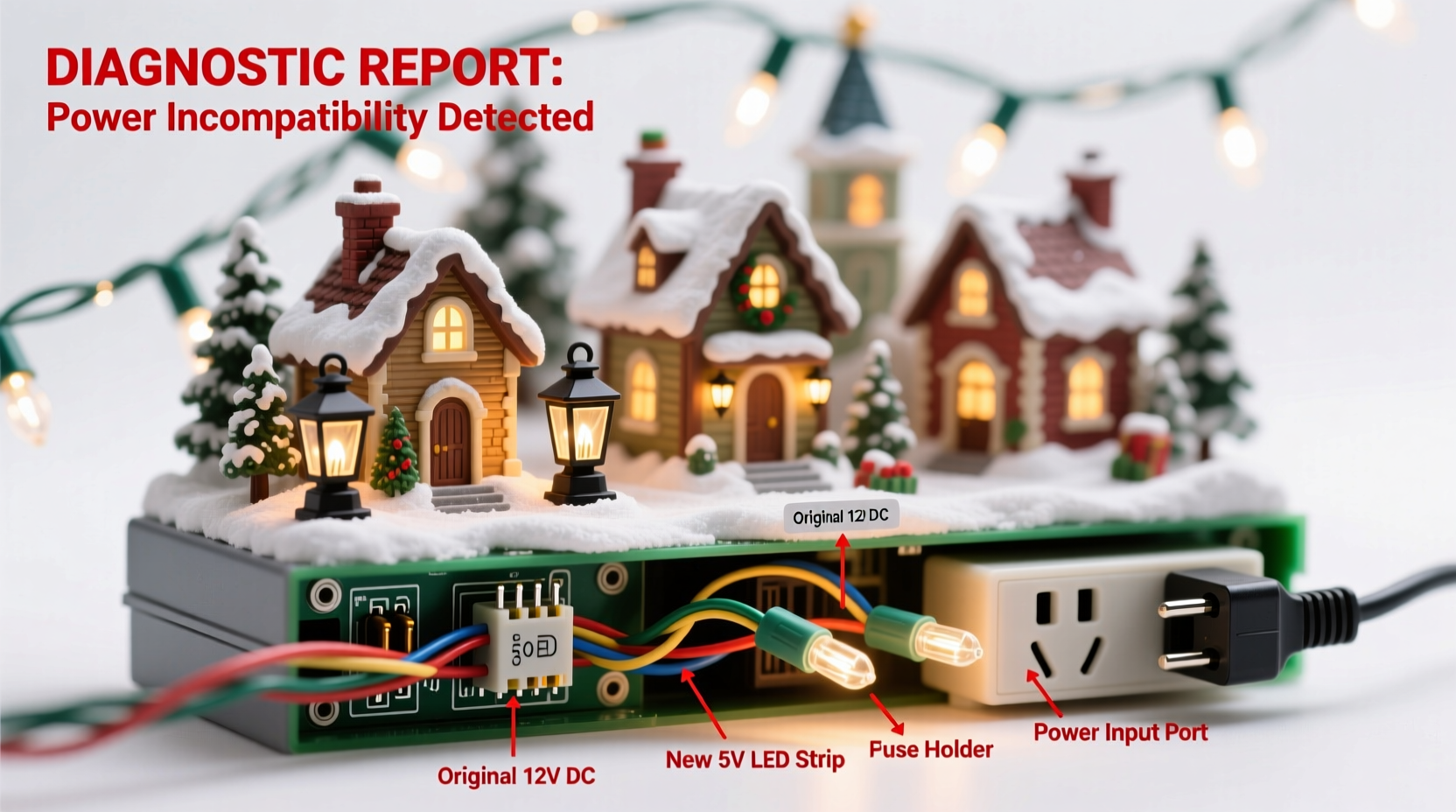

Diagnostic Checklist: Isolate the Problem in Under 10 Minutes

Before replacing transformers or rewiring, confirm the root cause with this field-proven sequence:

- ✅ Unplug everything except the village core (main base, transformer, and no added lights). Does it power on fully and hold steady for 5+ minutes?

- ✅ Test new lights independently—on a separate outlet, using their original adapter. Do they illuminate without flickering or tripping breakers?

- ✅ Check transformer temperature after 3 minutes of village-only operation. Warm is normal; hot enough to burn fingers indicates internal stress or failing insulation.

- ✅ Measure voltage at the village’s power input terminals (use a multimeter on AC or DC setting, matching your system). Readings below 90% of labeled output (e.g., <10.8V on a 12V system) point to transformer or wiring issues.

- ✅ Try one new light string at a time, waiting 90 seconds between additions. Note which string triggers failure—and whether it’s immediate or delayed.

Compatibility & Safety Comparison Table

| Light Type | Village Compatibility Risk | Safer Alternative | Why It Matters |

|---|---|---|---|

| Non-dimmable LED Mini Lights (with SMPS adapter) | High — Causes ground loops & ripple | 12V DC constant-current LED strips (UL-listed, low-ripple) | SMPS adapters inject high-frequency noise into shared neutrals; constant-current drivers provide clean, stable output. |

| Incandescent C7/C9 Strings (120V) | Medium-High — Overloads village transformers via shared outlets | Dedicated 120V circuit with GFCI-protected outlet | Villages rarely share circuits safely with high-wattage incandescents; voltage sags trigger controller lockups. |

| USB-Powered Micro-Lights (5V) | Low-Medium — Only if powered from same USB hub as village control unit | Separate wall-wart USB adapter (2.4A min) | Shared USB hubs introduce data-line noise and insufficient current—especially during animation cycles. |

| Smart RGB LED Strips (Wi-Fi/Bluetooth) | Very High — RF interference disrupts village timing signals | Wired-only analog LED strips (no wireless components) | 2.4GHz transmissions interfere with 433MHz or 315MHz village remote receivers and microcontroller clock stability. |

Real-World Case Study: The Lemax Alpine Village Incident

In December 2023, Sarah K. in Vermont assembled her Lemax Alpine Village—a $420 set with motorized ski lift, rotating gondola, and synchronized snowfall. After adding two 24V LED net lights (marketed as “village-safe”), the entire display powered down 8 seconds after activation—every single time. She replaced the included 40VA transformer twice, checked all connections, and even contacted Lemax support, who suggested “possible internal short.”

A local electrical technician visited with a clamp meter and oscilloscope. He discovered the net lights’ power supply was leaking 18V AC onto its DC output due to failed filtering capacitors. When connected to the village’s 24V input, this AC component overloaded the village’s voltage regulator IC, causing thermal shutdown. Replacing the lights’ adapter with a linear-regulated 24V supply resolved it instantly. Crucially, the village’s regulator was undamaged—just in protective lockout mode. Sarah regained full functionality without replacing a single village component.

“Modern Christmas villages are sophisticated embedded systems—not passive décor. They monitor voltage, current, temperature, and signal integrity in real time. What looks like ‘failure’ is usually graceful degradation or intelligent fault containment.” — Dr. Alan Rhee, Senior Electronics Engineer, Holiday Lighting Safety Institute

Step-by-Step Recovery Protocol

If your village has gone dark after adding lights, follow this precise sequence to restore operation—without risking further damage:

- Power Down & Disconnect: Unplug the village transformer AND all new lights from the wall. Wait 60 seconds for capacitors to discharge.

- Reset Internal Controllers: Locate any reset button (often recessed near the transformer port) or remove the battery from the village’s control module (if present) for 2 minutes.

- Verify Transformer Output: With multimeter probes on transformer leads, measure open-circuit voltage. It must be within ±5% of labeled rating (e.g., 11.4–12.6V for 12V). If outside range, replace transformer.

- Test Wiring Continuity: Set multimeter to continuity mode. Check each village building’s power input terminals for shorts (<1Ω resistance between + and –). Any reading below 5Ω indicates damaged internal wiring or LED array.

- Reintroduce Lights Gradually: Plug in ONE new light string—but power it from a separate, dedicated outlet. Use a heavy-duty extension cord (14 AWG) if needed. Observe village behavior for 3 minutes. Repeat only if stable.

- Install Isolation: Once confirmed compatible, add a ferrite choke (clip-on type) around both the village transformer cord and the light string cord, 2 inches from their plugs. This suppresses high-frequency noise coupling.

FAQ: Quick Answers to Critical Questions

Can I use a higher-wattage transformer to fix this?

No—unless explicitly approved by the manufacturer. Oversizing a transformer increases magnetic flux saturation, overheating internal village wiring and potentially damaging timing capacitors. Always match voltage exactly and increase VA rating by no more than 20% (e.g., 30VA → 36VA max).

Why does my village work fine with old lights but not new ones—even if they’re the same wattage?

Wattage ratings don’t reflect electrical “cleanliness.” Older incandescent strings draw smooth, resistive current. New LEDs draw pulsed, reactive current with high harmonic distortion—confusing village controllers designed for analog loads. It’s about waveform fidelity, not just power consumption.

Is there permanent damage if I left it plugged in for hours while malfunctioning?

Unlikely—if the village went completely dark (not flickering or smoking). Modern units include polyfuse protection that resets after cooling. However, repeated thermal cycling degrades solder joints over time. If recovery takes >3 attempts, inspect for discoloration near voltage regulators on the control board.

Conclusion: Restore Joy, Not Just Power

Your Christmas village isn’t broken—it’s communicating. That sudden silence isn’t a failure of craftsmanship; it’s a precisely calibrated response to an electrical condition your new lights introduced. By treating the system as the integrated electronic ecosystem it truly is—not just a collection of pretty buildings—you regain control. You’ll learn to read voltage drops like weather patterns, interpret transformer warmth like a diagnostic vital sign, and choose lights not just for sparkle, but for electrical harmony. These skills extend far beyond the holiday season: they build confidence in managing any low-voltage decorative system, from garden lighting to model railroads.

Start tonight. Grab your multimeter. Test that transformer. Try one light string—separately. Notice the difference between “no power” and “protection engaged.” In doing so, you’re not just fixing a display—you’re honoring the engineering behind the magic, and ensuring your village tells stories for years to come.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?