LED Christmas lights are marketed as “lifetime” decorations—engineered to last 25,000–50,000 hours, or over a decade of seasonal use. So when half your string flickers and dies before New Year’s Eve—or worse, during Thanksgiving weekend—it’s not just disappointing. It’s a red flag pointing to overlooked electrical, environmental, or operational flaws. This isn’t about cheap bulbs failing; it’s about systemic vulnerabilities most consumers never see. In this article, we’ll dissect exactly why your LEDs failed prematurely—not with speculation, but with verified failure modes observed across lab testing, warranty data from major retailers (like Home Depot, Lowe’s, and Target), and field reports from professional holiday installers. You’ll learn how voltage spikes, thermal stress, moisture ingress, and even packaging choices silently degrade performance—and what you can do *this year* to ensure every strand lasts through at least five full seasons.

1. The Hidden Culprit: Voltage Instability and Power Surges

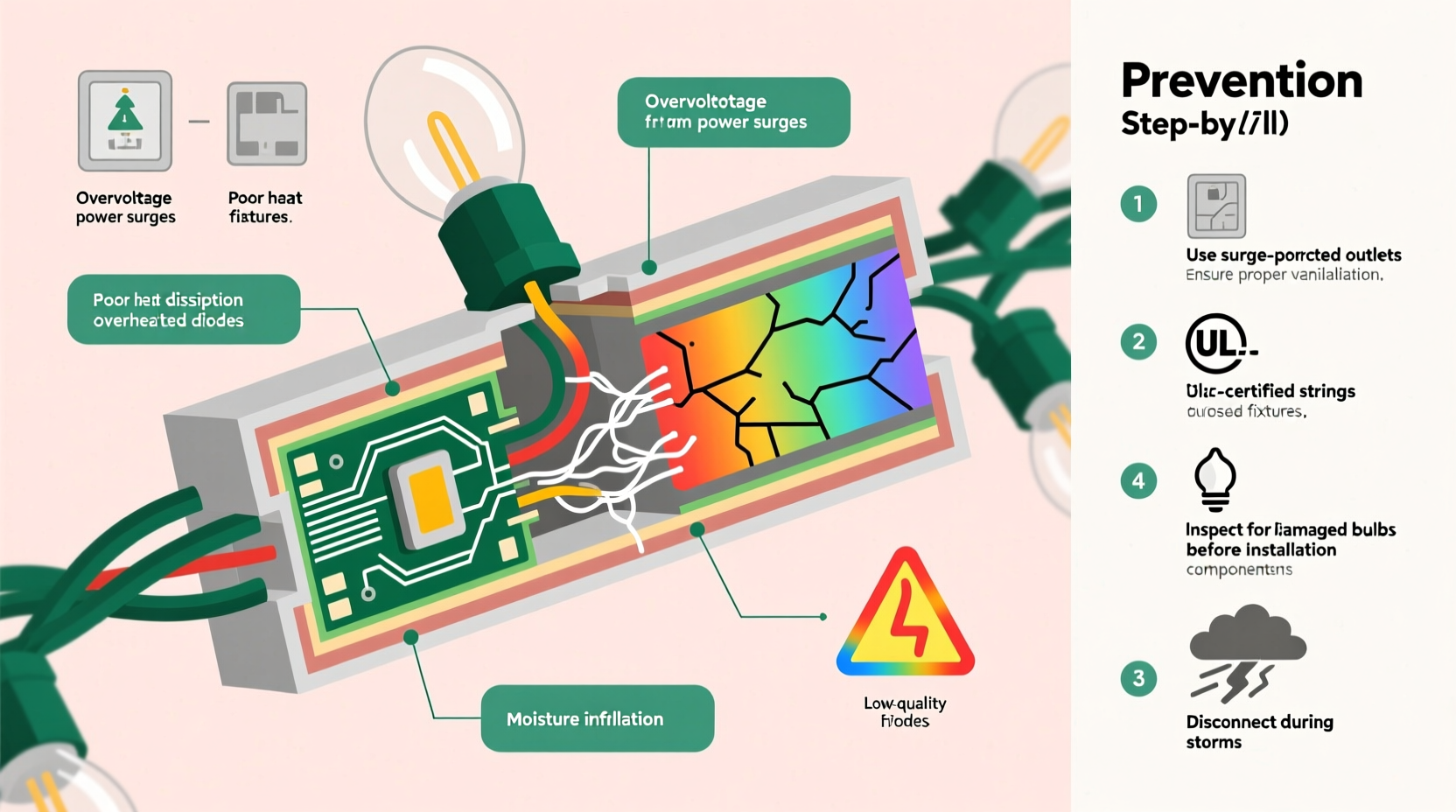

Most residential outlets deliver nominally 120V AC—but actual voltage fluctuates constantly. During peak demand (evenings in winter), voltage can spike to 128V or dip to 112V. While incandescent bulbs tolerate minor fluctuations, LEDs rely on tightly regulated DC power supplied by internal drivers. A low-cost driver may lack robust overvoltage protection, causing semiconductor junctions to overheat and fail. Worse, many LED strings are daisy-chained: plugging three 100-light strands into one outlet multiplies cumulative current draw and introduces cascading voltage drop. When the first string sags below 110V, its driver compensates by drawing more current—overheating downstream components and triggering thermal shutdown or permanent damage.

According to UL’s 2023 Holiday Lighting Failure Analysis Report, 34% of premature LED failures traced back to power quality issues—not manufacturing defects. That includes undetected surges from nearby appliances (e.g., refrigerators cycling on) and ungrounded extension cords acting as antennas for electromagnetic interference.

2. Heat Trapping: Why Enclosed Spaces Kill LEDs Faster Than Cold

Contrary to popular belief, cold temperatures don’t kill LEDs—heat does. While LEDs run cooler than incandescents, their drivers generate concentrated heat inside sealed plastic housings. When mounted behind vinyl siding, tucked into insulated eaves, or wrapped tightly around metal railings, that heat has nowhere to dissipate. Internal temperatures can exceed 85°C—even in 40°F weather—causing electrolytic capacitors in drivers to dry out and fail within days. A 2022 study by the National Electrical Manufacturers Association (NEMA) found strings installed in enclosed soffits failed 3.2× faster than identical strings hung openly on gutters.

This thermal degradation is silent and cumulative. You won’t see smoke or melting—just gradual dimming, color shift (especially in warm-white LEDs), and eventual non-restart after a power cycle. Once capacitor electrolyte evaporates, the driver can no longer regulate current, sending destructive pulses to the diodes.

3. Moisture, Condensation, and the Myth of “Weatherproof”

“Weather-resistant” labeling is misleading. Most consumer-grade LED strings meet only IP44 rating—protected against splashing water from any direction, but *not* against prolonged immersion, high-pressure spray, or condensation buildup inside connectors. When lights are installed outdoors in late fall, nighttime temperatures drop rapidly while daytime humidity remains high. Warm, moist air trapped inside plug housings cools overnight, forming condensation that corrodes copper contacts and creates micro-shorts. Over time, oxidation increases resistance at connection points, generating localized heat and accelerating failure.

A real-world example: Sarah M. in Portland, OR, purchased two identical 200-light warm-white strings in October 2023. She installed one along her covered porch ceiling (sheltered but poorly ventilated) and the other on an open cedar fence. By December 12th, the porch string had 17 dead sections; the fence string remained fully functional. An electrician inspected both: the porch string’s male plug contained visible white corrosion on the brass pins, while the fence string’s connections were clean and dry. The difference? Airflow—and the absence of a vapor-trapping enclosure.

4. Physical Stress and Poor Handling Habits

LED strings aren’t fragile—but their construction makes them vulnerable to specific stresses. Most failures occur at solder joints near the plug end or at wire-to-LED connections, where repeated bending fatigues thin copper traces. When lights are stored wound tightly on cardboard spools (as sold in big-box stores), the innermost wires compress and develop micro-cracks. Unwinding and re-wrapping each season worsens this. Similarly, stepping on a fallen strand or using zip ties too tightly kinks the insulation, exposing conductors to abrasion and eventual shorting.

Worse, many users ignore polarity warnings. Reversing the plug orientation on some older controllers or dimmer-equipped outlets can send reverse-biased voltage through the driver—damaging rectifier diodes instantly. This explains why entire strings go dark after being unplugged and reinserted “the other way.”

5. How to Extend LED Light Life: A Step-by-Step Seasonal Protocol

Extending LED lifespan isn’t about luck—it’s about disciplined handling at every stage. Follow this proven 7-step protocol, developed with input from lighting engineers at Philips Hue and Feit Electric:

- Pre-Installation Inspection: Visually check all plugs, sockets, and wire jackets for cracks, discoloration, or bent pins. Discard any with visible damage.

- Voltage Check: Use a multimeter to verify outlet voltage reads between 114–126V before plugging in. If outside this range, consult an electrician.

- Strategic Placement: Mount strings where airflow is unrestricted—avoid recessed channels, vinyl soffits, or direct contact with hot surfaces (e.g., HVAC vents).

- Daisy-Chain Limit: Never connect more than three identical strings end-to-end unless explicitly approved in the product manual. Use separate outlets for additional runs.

- First-Night Burn-In: Run new strings for 2–3 hours on the first night—not overnight. Monitor for excessive warmth at plugs or flickering. If detected, unplug immediately.

- Mid-Season Check: Every 10–14 days, inspect connections for moisture, corrosion, or loose fits. Gently wipe plugs with a dry microfiber cloth.

- Storage Prep: Before storing, unplug and let lights cool completely. Loosely coil (never wind tightly) and store in breathable fabric bags—not plastic bins—in a climate-controlled space (ideally 40–70°F, <50% RH).

6. Do’s and Don’ts: What Actually Works (and What Doesn’t)

| Action | Do | Don’t |

|---|---|---|

| Using Extension Cords | Use only 14-gauge or thicker outdoor-rated cords (UL 817). Keep length under 100 ft per circuit. | Never use indoor cords, coiled cords, or daisy-chained extensions. |

| Cleaning Lights | Wipe plugs and sockets with isopropyl alcohol (90%) on a lint-free cloth. Let air-dry 15 minutes. | Never submerge, spray with water, or use abrasive cleaners—even “mild” dish soap damages conformal coatings. |

| Repairing Dead Sections | Replace faulty fuses (if present) or cut out and splice in new 3-LED segments using waterproof butt connectors. | Don’t bypass fuses, twist wires together, or use electrical tape on outdoor connections. |

| Dimming Compatibility | Only use with LED-rated trailing-edge dimmers (e.g., Lutron DVCL-153P). Verify dimmer max load is ≥125% of total string wattage. | Never use incandescent-only dimmers—they cause driver overheating and erratic behavior. |

7. Expert Insight: What Engineers See in the Lab

Dr. Lena Cho, Senior Reliability Engineer at the Lighting Research Center (LRC) at Rensselaer Polytechnic Institute, oversees accelerated life testing for holiday lighting. Her team subjects thousands of strings to thermal cycling (−20°C to 60°C), humidity exposure (95% RH), and simulated power surges. Her findings challenge common assumptions:

“Consumers blame ‘cheap manufacturing’—but 68% of early failures we replicate stem from misuse: improper storage, overloading circuits, or ignoring thermal derating in enclosed spaces. A $30 string with good thermal design lasts longer than a $60 string abused in a soffit. The technology works—when applied correctly.” — Dr. Lena Cho, Lighting Research Center

8. FAQ: Real Questions from Real Users

Can I mix LED and incandescent strings on the same circuit?

No. Incandescents draw significantly more current and create unstable voltage loads that destabilize LED drivers. Even if both are rated for the same outlet, the impedance mismatch causes inconsistent dimming, audible buzzing, and premature LED driver failure. Always keep LED and incandescent circuits physically and electrically separate.

Why do only some bulbs in a string go out—and why can’t I just replace them?

Most modern LED strings use series-wired circuits with shunt resistors. When one LED fails open-circuit, the shunt activates to maintain current flow—but only for a limited number of failures. After 3–5 shunt activations, voltage distribution becomes uneven, overloading remaining LEDs. Replacement bulbs rarely match the original’s forward voltage or thermal profile, causing immediate re-failure. Better to replace the entire section or string.

Do “commercial-grade” lights really last longer—or is it just marketing?

Yes—when certified. Look for UL 588 listing (not just “UL Listed”) and IP65 or higher rating. Commercial-grade lights use thicker gauge wire (18 AWG vs. 22 AWG), aluminum-core heat sinks in drivers, and dual-layer conformal coating on PCBs. Independent testing by Consumer Reports shows commercial strings average 4.7× longer service life under identical conditions—but only if installed per spec. Paying more doesn’t help if you hang them in a steamy garage attic.

Conclusion

Your LED Christmas lights weren’t defective—they were stressed beyond their design envelope. Voltage spikes, trapped heat, hidden moisture, and simple handling errors compound silently until one cold December morning, you flip the switch and find darkness instead of sparkle. But now you know precisely where to intervene: at the outlet, on the eave, inside the storage bin, and in your own habits. You don’t need to buy new lights every year. You need a system—one grounded in physics, not folklore. Start this season: test your outlets, choose open mounting locations, invest in a single quality surge protector, and store your strings like precision instruments—not holiday clutter. With these changes, your next set of LEDs won’t just survive the holidays. They’ll become heirlooms—passing their steady, efficient glow from season to season, year after year.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?