Airplane windows may look simple, but every element of their design serves a crucial function—especially that small, seemingly insignificant hole near the bottom of each window pane. Often mistaken for a manufacturing flaw or a vent for air circulation, this tiny perforation is actually a vital component in maintaining cabin safety and structural integrity at high altitudes. Understanding why it exists requires a dive into the physics of flight, pressure differentials, and engineering foresight.

Commercial aircraft routinely fly above 30,000 feet, where atmospheric pressure is less than a quarter of what it is at sea level. At these altitudes, humans cannot survive without pressurized cabins. To keep passengers safe and comfortable, the cabin is sealed and pressurized to simulate conditions at around 6,000 to 8,000 feet. But this internal pressure creates immense stress on the aircraft’s structure—including its windows. That’s where the tiny hole, known as the *bleed hole* or *breather hole*, comes into play.

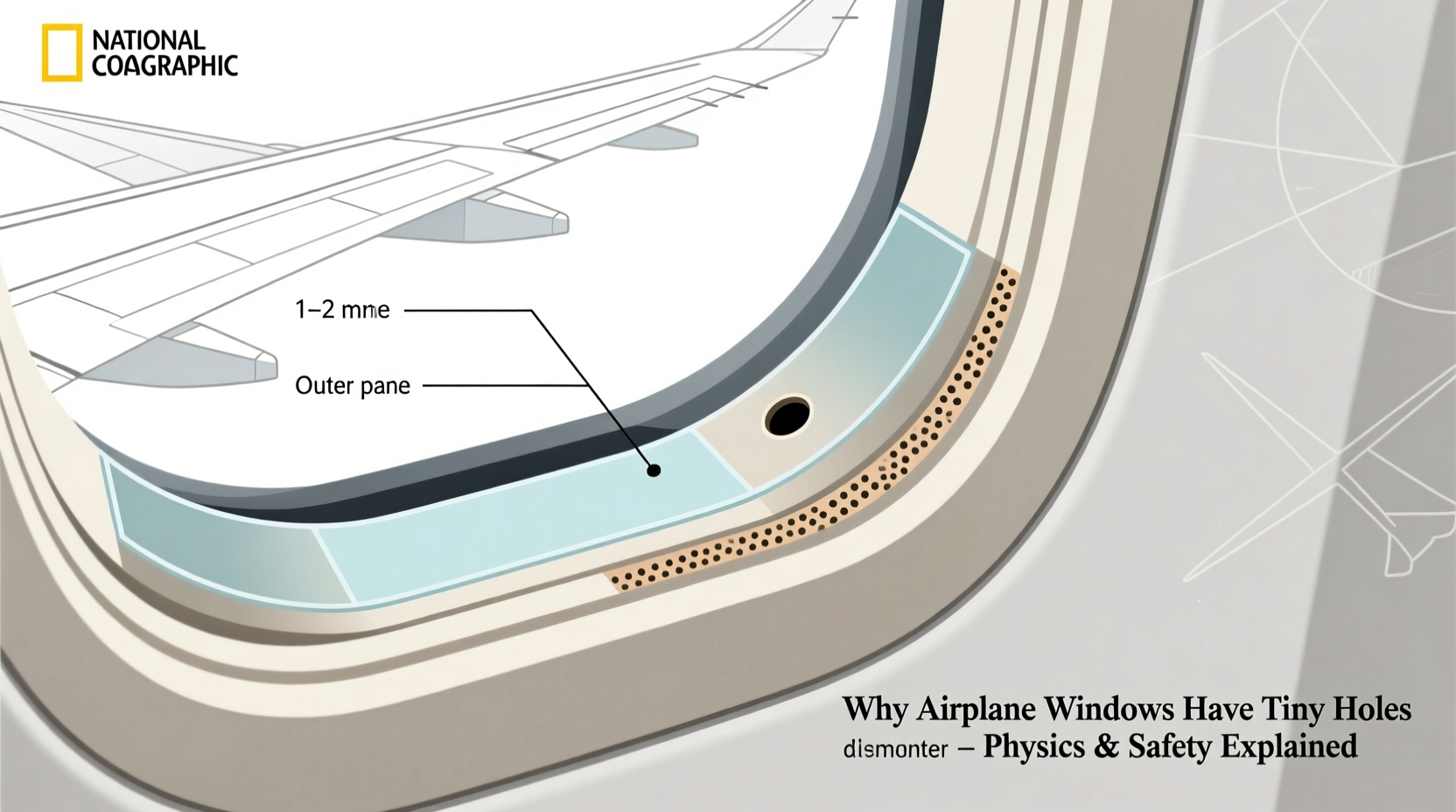

The Three-Layer Window System

Aircraft windows aren’t single panes of glass. They are complex, multi-layered systems designed with redundancy and safety in mind. Each passenger window consists of three distinct acrylic or polycarbonate layers:

- Outer pane: The primary structural barrier exposed to external atmospheric conditions.

- Middle pane: A backup layer that supports the outer pane and contains the bleed hole.

- Inner pane: The scratch-resistant layer closest to passengers, mainly for protection against accidental impact.

The outer and middle panes are both load-bearing, meaning they help maintain cabin pressure. The inner pane does not bear pressure—it's essentially a shield against spilled drinks, fingers, or camera lenses. Between the outer and middle panes lies a small air gap connected to the cabin atmosphere via the bleed hole.

Physics of Pressure: How the Hole Prevents Window Failure

The core purpose of the tiny hole is pressure regulation. During ascent, the aircraft climbs rapidly through decreasing atmospheric pressure. Inside the cabin, air compressors pump conditioned air to maintain breathable conditions. This creates a pressure differential—the inside of the plane is much higher than the outside.

This differential exerts outward force on all cabin surfaces, including windows. If all three panes were equally rigid and sealed, the full force would be applied suddenly and unevenly, increasing the risk of cracking or shattering. Instead, the breather hole allows controlled pressure transfer between the cabin and the air gap between the outer and middle panes.

Here’s how it works step by step:

- As the plane ascends, cabin pressure increases.

- The pressure builds against the inner pane first, which doesn’t bear load.

- The middle pane, containing the hole, allows slow airflow into the inter-pane cavity.

- The outer pane takes nearly all the pressure stress during flight because it separates the low external pressure from the higher pressure in the gap.

- The hole ensures the middle pane experiences minimal net pressure difference, preserving it as a functional backup.

In essence, the hole shifts the structural burden onto the strongest layer—the outer pane—while keeping the middle pane intact for emergencies.

“Without the breather hole, the middle pane would be subjected to the same extreme forces as the outer pane, eliminating its value as a fail-safe.” — Dr. Alan Reed, Aerospace Structural Engineer, MIT Lincoln Laboratory

Safety Redundancy: What Happens If a Pane Fails?

Redundancy is a cornerstone of aviation safety. Every critical system has backups, and windows are no exception. The three-layer design ensures that even if one pane fails, the others can still maintain cabin integrity.

Consider a real-world scenario: In 2018, a Southwest Airlines flight experienced rapid depressurization after an engine failure caused debris to strike a window. One passenger was partially pulled out of the plane before being restrained. While tragic, the incident revealed the resilience of aircraft design—the fuselage did not rupture further, and the pilots safely landed the plane.

In that case, although the window was compromised, the surrounding structure held. Had the window lacked redundant layers—or if the pressure had been mismanaged across panes—the outcome could have been far worse. The breather hole ensures that under normal conditions, only the outer pane bears the brunt of pressure, leaving the middle pane ready to take over if needed.

If the outer pane cracks or loses integrity:

- The middle pane is already acclimated to lower pressure (due to the bleed hole).

- It immediately becomes the new primary pressure barrier.

- Cabin pressure remains stable enough for pilots to initiate descent.

This layered fail-safe approach gives crews time to respond without catastrophic decompression.

Condensation and Fog Prevention

Beyond pressure control, the tiny hole also helps manage moisture. Temperature extremes at high altitudes can cause condensation to form between window layers. Moisture buildup not only obstructs visibility but can lead to long-term material degradation, such as delamination or frost formation.

The breather hole allows humid cabin air trapped between the inner and middle panes to escape gradually. As the plane climbs and cabin pressure changes, moist air flows out through the hole rather than condensing on cold surfaces. This keeps the view clear and protects the integrity of the acrylic materials over thousands of flight cycles.

Additionally, the airflow prevents fogging during ground operations when humidity levels vary significantly—such as in tropical climates or rainy weather. Without this ventilation, passengers might face obscured views, and maintenance crews would need to replace windows more frequently due to internal clouding.

| Function | Purpose | Consequence if Missing |

|---|---|---|

| Pressure Equalization | Distributes stress to outer pane only | Increased risk of dual-pane failure |

| Backup Layer Preservation | Keeps middle pane intact for emergencies | Loss of redundancy; higher failure risk |

| Moisture Venting | Prevents condensation between panes | Fogging, reduced visibility, material damage |

| Structural Monitoring | Visible signs of wear indicate service needs | Undetected degradation leading to failure |

Maintenance and Inspection Protocols

Aircraft windows undergo rigorous inspection during routine maintenance checks. Technicians examine all three panes for scratches, crazing (micro-cracks), delamination, and seal integrity. The presence of the breather hole actually aids in diagnostics.

For example, if the hole becomes clogged with dirt, tape, or cleaning residue, it disrupts the pressure balance. Maintenance logs often include specific checks for obstruction around the window frame and hole clearance. Even minor blockages can lead to uneven stress distribution, accelerating wear on the middle pane.

Airlines follow guidelines set by manufacturers like Boeing and Airbus, which specify replacement intervals based on flight hours, pressurization cycles, and visible damage. A typical commercial jet undergoes about 500–700 pressurization cycles per year. Over time, repeated expansion and contraction fatigue materials—even durable acrylics.

Common Misconceptions About the Hole

Despite its importance, the hole is frequently misunderstood. Some common myths include:

- Myth: It lets fresh air into the cabin.

Reality: No outside air enters through the window. Cabin air comes from compressed engine bleed air or onboard compressors. - Myth: It’s a microphone or surveillance device.

Reality: There is no audio equipment embedded in standard passenger windows. The hole is purely mechanical. - Myth: Covering it improves comfort.

Reality: Blocking the hole risks pressure imbalance and potential window damage. Never place stickers, tape, or fingers over it.

Understanding the true function dispels fear and promotes respect for engineered solutions that protect millions of travelers daily.

Checklist: What Passengers Should Know About Airplane Windows

To ensure safety and awareness, here’s a practical checklist for air travelers:

- Never cover or obstruct the small hole in the window.

- Avoid pressing cameras, phones, or hard objects against the window during takeoff and landing.

- Report any visible cracks, fogging between panes, or unusual noises near windows to crew immediately.

- Keep window shades open during takeoff and landing for emergency visibility.

- Don’t worry if the window feels warm or vibrates slightly—this is normal due to pressure and airflow.

FAQ: Frequently Asked Questions

Can the hole break or get damaged?

The hole itself is precision-drilled and highly durable. However, surrounding seals or acrylic layers can degrade over time. Routine inspections catch issues before they become hazardous. If the hole were to crack or deform significantly, maintenance crews would replace the entire window unit.

What happens if the outer pane cracks?

If the outer pane develops a crack, the middle pane is already in place to handle cabin pressure. Pilots would begin a controlled descent to a safer altitude while monitoring cabin integrity. Complete window blowout is extremely rare due to this redundancy.

Do private jets and smaller planes have the same window design?

Many do, especially those that cruise at high altitudes and use pressurized cabins. However, some small piston-engine aircraft flying below 10,000 feet may use simpler single-pane windows since they don’t experience extreme pressure differentials.

Conclusion: Engineering Elegance in Plain Sight

The tiny hole in airplane windows is a masterclass in subtle engineering. It performs multiple life-preserving functions—balancing pressure, preserving backup structures, and preventing moisture damage—all without drawing attention. Its existence underscores a fundamental truth in aviation: safety is built into every detail, no matter how small.

Next time you gaze out at the clouds, take a moment to appreciate the science behind the glass. That unassuming dot is not a defect—it’s a guardian. It works silently across thousands of flights, ensuring that the boundary between you and the thin air at 35,000 feet remains strong, stable, and secure.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?