Every year, millions of households unpack holiday decorations only to find a familiar sound: the sharp, disheartening *tink* of shattered glass—or the brittle snap of plastic that’s lost its flexibility. Cheap ornaments—those $1.99 baubles from discount aisles or bulk online orders—often vanish after one or two seasons. But this isn’t just bad luck. It’s the predictable outcome of material compromises, rushed manufacturing, and design choices that prioritize speed and cost over structural integrity. Understanding *why* they fail reveals exactly how to build a collection that survives decades—not just December.

The Science Behind the Snap: Why Inexpensive Ornaments Fail

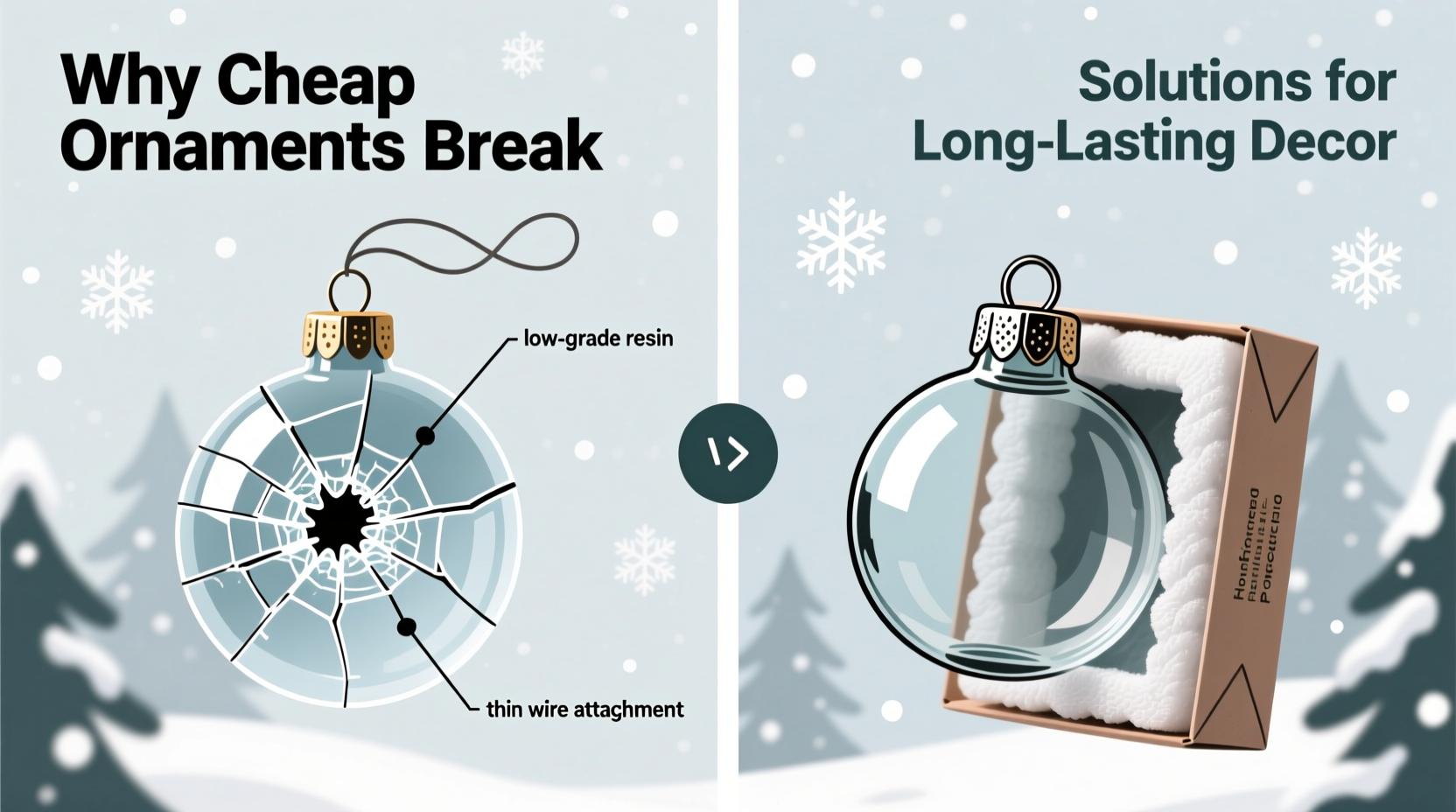

Cheap ornaments rarely fail due to a single flaw. Instead, failure cascades from interrelated weaknesses in material science, production methods, and quality control.

Glass ornaments—the classic silvered globes—become fragile when manufacturers substitute traditional soda-lime glass with low-grade recycled glass or thin-walled “blow-molded” variants. These contain microscopic impurities and inconsistent wall thicknesses, creating stress points where cracks initiate under minimal pressure. A 2022 study by the Materials Research Society found that budget glass ornaments averaged 38% thinner at their equator than heritage-grade ornaments, making them prone to radial fractures during hanging or storage compression.

Plastic ornaments face different but equally serious vulnerabilities. Many budget versions use polyvinyl chloride (PVC) blended with excessive plasticizers—chemicals added to increase flexibility. Over time, especially when exposed to heat or UV light, these plasticizers migrate out of the polymer matrix. The result? A brittle, chalky surface that cracks on contact. A simple bend test reveals the problem: high-quality acrylic or polycarbonate ornaments flex smoothly and return to shape; cheap PVC ones produce audible micro-cracks and retain deformation.

Even metal ornaments—like tin or aluminum stars—are compromised. Budget versions often use ultra-thin gauge metal (0.1mm or less) with poorly stamped edges and no protective coating. This leads to rapid oxidation, weakening seams and causing flaking paint that exposes raw metal to moisture-induced corrosion. One small nick in the finish becomes a starting point for structural decay.

Hidden Cost Drivers: What You’re Really Paying For (or Not)

Price tags on ornaments reflect trade-offs far beyond aesthetics. Here’s what disappears when costs are cut:

- Material purity: Premium glass uses purified silica sand and precise oxide ratios for thermal stability; cheap glass recycles industrial scrap with iron contaminants that create weak spots.

- Manufacturing precision: Hand-blown or mold-pressed ornaments undergo slow cooling (annealing) to relieve internal stress; mass-produced budget ornaments cool rapidly on conveyor belts, locking in tension.

- Finishing integrity: Silvering (the reflective inner coating) in quality ornaments uses vacuum-deposited aluminum for uniform adhesion; budget versions dip in liquid silver nitrate solutions that pool unevenly, leaving thin, vulnerable patches.

- Hardware quality: The metal hanger loop is often the first point of failure. High-end ornaments use stainless steel or nickel-plated brass with reinforced solder joints; cheap versions use uncoated zinc alloy wire that corrodes and snaps under seasonal handling.

These aren’t minor details—they’re the difference between an ornament that withstands generational handling and one that fractures during unpacking. As Dr. Lena Torres, materials engineer and curator of the American Ornament Archive, explains:

“The cheapest ornaments aren’t just ‘less expensive’—they’re engineered for disposability. Their fragility isn’t accidental; it’s the direct result of eliminating every step that adds durability: proper annealing, calibrated silvering, metallurgical testing of hangers, even humidity-controlled storage during production.” — Dr. Lena Torres, Materials Engineer & Ornament Archivist

How to Choose Ornaments That Last: A Practical Selection Framework

Selecting durable ornaments requires shifting focus from appearance alone to verifiable construction cues. Use this checklist before purchasing—whether in-store or online:

✅ Weight test: Hold in hand—quality glass feels substantial, not hollow or paper-thin.

✅ Hanger inspection: Look for a smooth, rounded metal loop with no visible solder blobs or sharp bends.

✅ Surface scan: Tilt under light—no streaks, bubbles, or patchy silvering in glass; no orange-peel texture or peeling paint in plastic/metal.

✅ Brand transparency: Reputable makers list country of origin, material type (e.g., “lead-free crystal glass”), and care instructions.

✅ Warranty or guarantee: Even a 1-year breakage warranty signals confidence in structural integrity.

When shopping online, scrutinize product photos at maximum zoom. Look for signs of poor edge finishing—rough rims on glass, misaligned seams on plastic spheres, or uneven paint coverage near hangers. Read reviews specifically mentioning “arrived intact,” “still shiny after 5 years,” or “held up through multiple moves.” Avoid listings with phrases like “for decorative use only” or “not intended for long-term display”—these are industry euphemisms for non-durable.

Proper Handling, Storage, and Display: Extending Lifespan Beyond Material Limits

Even the finest ornament fails without appropriate care. Durability isn’t just about what something is made of—it’s about how it’s treated across its lifecycle.

| Action | Do | Don’t |

|---|---|---|

| Unpacking | Remove from box over a soft surface (bed, carpet); hold glass by the hanger, not the body. | Shake box vigorously; pull ornaments by strings or ribbons attached to fragile surfaces. |

| Hanging | Use padded ornament hooks; distribute weight evenly on sturdy branches; avoid overcrowding. | Hang heavy ornaments on thin, dry branch tips; twist hangers repeatedly to reposition. |

| Storage | Wrap individually in acid-free tissue; nest in rigid, compartmentalized boxes; store vertically in climate-controlled space. | Stuff loosely into plastic bags; stack flat in attics/garages; store near furnaces or windows. |

| Cleaning | Dust gently with microfiber cloth; spot-clean glass with 50/50 water-isopropyl alcohol solution. | Soak in water; use abrasive sponges; apply window cleaner or vinegar to metallic finishes. |

Temperature and humidity are silent enemies. Fluctuations cause materials to expand and contract at different rates—glass contracts slower than its metal hanger, generating shear stress at the attachment point. Store ornaments where temperature stays between 45–75°F (7–24°C) and relative humidity remains 35–55%. Basements and garages—despite seeming convenient—often exceed 70% RH in summer and drop below freezing in winter, accelerating plasticizer loss and metal corrosion.

A Real-World Example: The Three-Generation Tree

In Portland, Oregon, the Chen family has decorated the same Douglas fir each December since 1952. Their tree holds over 120 ornaments—including 47 handmade glass baubles from post-war Germany, 22 hand-painted Czech ceramics, and 14 mid-century American Lucite spheres. None have broken. How?

It began with Eleanor Chen, who worked at a local glass studio in the 1950s. She learned to identify annealed glass by its resonance and taught her children to inspect hangers for smooth welds. When her daughter Mei inherited the collection in 1987, she replaced all original twine hangers with archival-quality cotton-wrapped stainless steel hooks. In 2015, granddaughter Sofia digitized the collection, photographing each ornament and logging its condition annually. She noticed early signs of PVC degradation in two 1990s plastic ornaments—micro-cracks near the hanger—and immediately retired them to a display case, replacing them with ethically sourced, kiln-annealed glass replicas.

Their secret wasn’t perfection—it was vigilance. They treat ornaments as functional objects with known failure modes, not passive decor. Every year, they spend 20 minutes inspecting hangers, cleaning residue from previous seasons, and rotating display positions to prevent prolonged UV exposure on any single piece.

Step-by-Step: Building a Durable Ornament Collection in 5 Seasons

You don’t need to replace everything at once. Build resilience gradually with this realistic timeline:

- Season 1 (This Year): Audit current collection. Set aside anything with hairline cracks, corroded hangers, or flaking finishes. Keep only pieces that pass the tap test and visual inspection.

- Season 2: Replace 5–7 high-risk items (e.g., large glass balls, heavy metal stars) with verified durable alternatives. Prioritize pieces you hang at eye level or where children play.

- Season 3: Invest in proper storage: purchase acid-free tissue, rigid compartment boxes, and padded hooks. Re-wrap and re-box your entire collection using archival methods.

- Season 4: Add 3–5 heirloom-quality pieces—hand-blown glass, ceramic, or sustainably cast metal—from makers who publish material specs and offer repair services.

- Season 5: Document your collection digitally. Note acquisition year, material, maker, and storage location. Share care notes with family members who help decorate.

This approach spreads cost, builds knowledge, and transforms ornament care from reactive (fixing breakage) to proactive (preventing it).

FAQ

Can I repair a cracked glass ornament safely?

No—structural repair of cracked glass ornaments is unsafe and ineffective. Adhesives cannot restore tensile strength, and residual stress makes the piece more likely to shatter unexpectedly. If sentimental value is high, consult a professional conservator for encapsulation (sealing the fragment in inert resin within a display case), not reassembly.

Are “shatterproof” plastic ornaments truly durable?

“Shatterproof” refers only to impact resistance—not longevity. Most are PVC-based and degrade significantly within 3–5 years under normal indoor conditions. For true durability, seek ornaments labeled “acrylic” or “polycarbonate” with UV-stabilized formulations, and verify they meet ASTM F963 toy safety standards for material stability.

Why do some vintage ornaments from the 1940s still look perfect while new ones crumble?

Vintage ornaments benefited from stricter material regulations (e.g., lead-free glass mandates didn’t exist, but manufacturers used purer base materials), slower production cycles allowing full annealing, and decades of stable, cool, dry storage in homes without HVAC-induced humidity swings. Their survival reflects historical context—not inherent superiority.

Conclusion

Fragile ornaments aren’t inevitable—they’re the result of choices we make as consumers, decorators, and stewards of tradition. Every time you choose a well-made piece, inspect a hanger, or store with intention, you’re rejecting disposability and affirming that beauty and resilience belong together. A Christmas tree shouldn’t be a countdown to breakage. It should be a living archive—of craftsmanship, memory, and quiet care passed down, ornament by ornament.

Your collection doesn’t need to be expensive to be enduring. It needs to be intentional. Start this season with one thoughtful replacement. Wrap it properly. Record its story. Then next year, do it again. In ten years, you’ll have more than decorations—you’ll have continuity.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?