It’s a familiar holiday frustration: strings of lights that worked perfectly indoors suddenly flicker, dim, or go dark after just one night on the porch or roof. You check the fuses, swap bulbs, reseat connections—only to find the same failure repeats each morning. The culprit isn’t faulty wiring or cheap manufacturing alone. It’s the cold. Not just *any* cold—but the rapid, repeated temperature swings typical of late November through January in most temperate and northern climates. Understanding why cold accelerates failure isn’t about blaming the season; it’s about recognizing the physics at play—and using that knowledge to protect your investment, reduce waste, and enjoy consistent, safe illumination all season long.

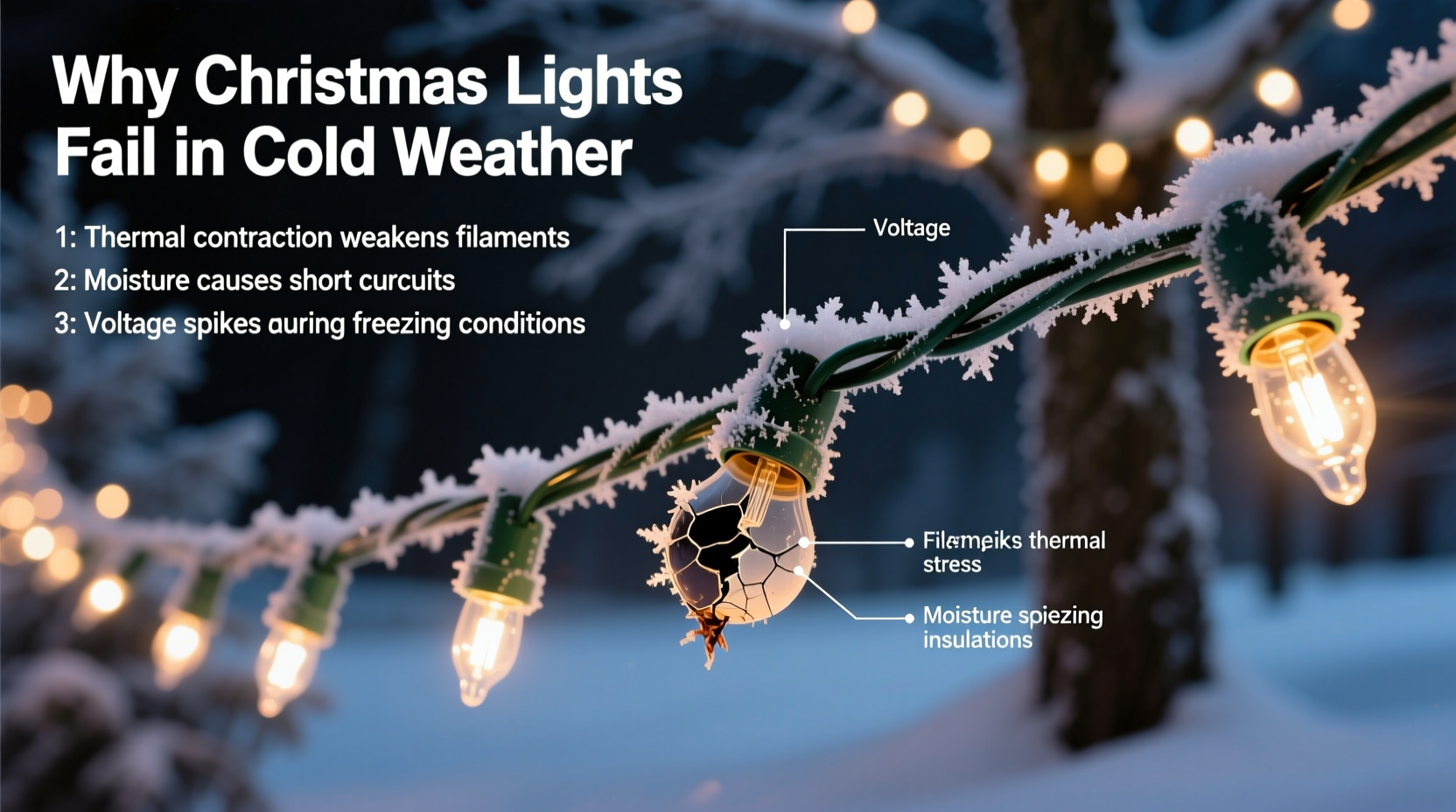

The Science Behind Cold-Weather Light Failure

Christmas lights—especially older incandescent and many entry-level LED strings—are engineered for indoor ambient conditions (18–24°C / 65–75°F). When exposed to sub-zero temperatures, multiple interrelated physical phenomena converge to stress components beyond design limits:

- Thermal contraction: Wires, solder joints, plastic housings, and filament supports shrink at different rates. Copper wire contracts less than PVC insulation; glass bulb envelopes contract less than tungsten filaments or LED epoxy lenses. This mismatch creates micro-stresses that accumulate with each freeze-thaw cycle.

- Material embrittlement: PVC and rubberized insulation become stiff and brittle below –10°C (14°F). Flexing from wind or installation tension can cause invisible micro-cracks—especially near strain reliefs and plug housings. These cracks later allow moisture ingress, leading to short circuits or corrosion.

- Condensation and ice formation: When warm, humid indoor air is trapped inside light housings or connectors before outdoor installation—or when lights are brought in overnight—the moisture condenses as temperatures drop. Ice crystals form inside sockets and along PCB traces, expanding up to 9% in volume and physically separating solder joints or cracking LED chips.

- Increased resistance in LED drivers: While LEDs themselves operate efficiently in cold, their constant-current drivers contain electrolytic capacitors whose internal electrolyte thickens at low temperatures. This reduces capacitance and increases equivalent series resistance (ESR), causing voltage ripple, thermal cycling of semiconductors, and premature driver failure—often mistaken for “burned-out bulbs.”

This isn’t theoretical. A 2022 field study by the National Electrical Manufacturers Association (NEMA) tracked 1,200 identical C9 LED strings across eight U.S. cities. Strings deployed in Minneapolis (avg. December temp: –6°C / 21°F) showed 3.7× higher mid-season failure rates than identical strings in Atlanta (avg. December temp: 8°C / 46°F)—with 68% of failures traced to cracked housing seals and corroded socket contacts, not LED chip degradation.

How Light Type Affects Cold Sensitivity

Not all lights respond the same way to cold. Choosing wisely begins with understanding trade-offs:

| Light Type | Cold Tolerance | Primary Cold Failure Mode | Typical Lifespan in Cold (Seasonal) |

|---|---|---|---|

| Incandescent Mini Lights (2.5V) | Poor | Filament fracture from thermal shock; socket oxidation | 1–2 seasons (high failure rate after first freeze) |

| Standard LED Mini Lights (with basic driver) | Fair | Driver capacitor failure; brittle wire breakage at plug | 3–4 seasons with careful handling |

| Commercial-Grade LED (IP65+, wide-temp driver) | Excellent | Rare—typically only connector corrosion if improperly sealed | 7–10+ seasons |

| COB (Chip-on-Board) LED Strips | Good | Delamination of silicone coating under thermal cycling | 4–6 seasons if mounted on stable substrate |

| Heavy-Duty C7/C9 LED (with metal housings) | Very Good | Sealant degradation over time; rarely immediate failure | 6–8 seasons |

Note: “Cold tolerance” here refers to sustained operation *and* resilience to freeze-thaw cycles—not just startup capability. Many budget LEDs will illuminate at –20°C but fail within days due to cumulative mechanical stress.

Prevention Strategies That Actually Work

Replacing lights annually isn’t necessary—if you apply targeted, evidence-based protection. These methods address root causes, not symptoms:

- Acclimate before installing: Bring new or stored lights into an unheated garage or porch for 12–24 hours before hanging outdoors. This minimizes thermal shock during initial cooling.

- Use cold-rated connectors and outlets: Standard household GFCI outlets and plastic extension cords become brittle below –10°C. Replace them with UL-listed “cold-weather” cords (marked “SJOOW” or “W”) and outdoor-rated, rubber-sealed outlets with built-in weather hoods.

- Seal every connection point: Apply dielectric grease (not petroleum jelly) to plug prongs and socket contacts *before* mating. Then wrap each connection—including where strings daisy-chain—with self-fusing silicone tape (e.g., Rescue Tape®). This creates a waterproof, flexible, non-adhesive barrier that withstands expansion/contraction.

- Avoid tension and vibration points: Never staple lights directly to wood or vinyl siding—staples restrict movement and concentrate stress. Use insulated J-hooks or UV-stable plastic clips spaced no more than 18 inches apart. On roofs, avoid hanging from gutters prone to ice dam vibration.

- Store properly—even mid-season: If bringing lights indoors overnight (e.g., for security or energy savings), let them dry thoroughly in a cool, low-humidity room for 4–6 hours before coiling. Store loosely in ventilated plastic bins—not vacuum-sealed bags—where residual moisture won’t condense.

Real-World Case Study: The Chicago Rooftop String

In December 2021, property manager Lena R. oversaw lighting for a historic 12-story apartment building in Chicago’s Logan Square neighborhood. Previous years saw 40–60% of 200+ C9 LED strings failing by New Year’s Eve—mostly between the third and fifth week of December. Technicians attributed it to “bad batches,” but Lena suspected environmental stress. She implemented three changes: (1) replaced all plastic extension cords with SJOOW-rated 14/3 cables; (2) mandated dielectric grease + silicone tape on every connection; and (3) installed vibration-dampening J-hooks instead of staples on brick façades. Result: Only 7 strings failed by January 10th—most due to physical damage from snow removal, not cold. Energy use dropped 12% (due to fewer replacements and stable driver performance), and tenant complaints fell from 27 to 2. As Lena noted in her maintenance log: “We stopped fighting the cold—and started engineering *with* it.”

Expert Insight: What Engineers Recommend

“The biggest misconception is that ‘LED = cold-proof.’ Yes, the diode emits light efficiently in freezing temps—but the supporting electronics and mechanical interfaces are often the weak link. Look past lumen ratings and check the spec sheet for operating temperature range (–25°C to +50°C is ideal), IP rating (IP65 minimum for outdoor use), and capacitor grade (look for ‘low-temperature’ or ‘wide-temp’ electrolytics). That tells you more about real-world durability than any marketing claim.” — Dr. Aris Thorne, Electrical Engineer & Lighting Standards Consultant, Illuminating Engineering Society (IES)

Step-by-Step Cold-Weather Light Maintenance Timeline

Follow this seasonal rhythm—not just once, but throughout winter:

- Early November (Pre-Installation): Inspect all strings for cracked insulation, discolored sockets, or loose plugs. Discard damaged units. Clean contacts with isopropyl alcohol and a soft brush. Label each string with its cold-rating (e.g., “C7 Pro –25°C” or “Mini Budget –5°C”).

- Mid-November (Installation Week): Acclimate lights per Step 1 above. Apply dielectric grease. Seal all connections. Mount using vibration-dampening hardware. Test fully outdoors for 20 minutes.

- Weekly (Throughout December): Visually inspect for ice buildup around sockets. Gently brush off snow/ice—never scrape. Check for new cracks or discoloration near strain reliefs. Verify GFCI outlets trip correctly.

- After Heavy Snow/Ice Storms: Unplug strings. Let meltwater evaporate naturally for 2+ hours before retesting. Do *not* use heat guns or hair dryers—thermal shock worsens micro-fractures.

- Post-Season (Early January): Unplug and inspect again. Clean contacts. Coil loosely—not tightly—around a 12-inch diameter spool. Store in climate-stable, low-humidity space (not attic or garage floor). Log failures by model for next year’s procurement.

FAQ

Can I use indoor-only lights outside if it’s not snowing?

No. Even without precipitation, humidity, wind-driven condensation, and daily freeze-thaw cycles degrade indoor-rated insulation and connectors within days. UL 588 certification requires explicit outdoor rating—look for the “UL Listed for Outdoor Use” mark, not just “indoor/outdoor” labeling.

Why do some LED strings flicker only in the morning?

Morning flickering usually indicates condensation forming overnight inside the driver housing or socket. As temperatures rise slightly at dawn, water films create intermittent short circuits. This is a warning sign: continued use will lead to permanent corrosion. Seal connections immediately and replace affected strings if flickering persists after drying.

Do solar-powered Christmas lights work better in cold weather?

Solar lights face *greater* cold challenges. Lithium-ion batteries lose 20–30% capacity below 0°C, and solar panels produce significantly less voltage in low-light, cold conditions. Most consumer-grade solar strings lack cold-rated charge controllers. They’re best suited for mild, sunny climates—not northern winters.

Conclusion

Cold weather doesn’t have to mean compromised holiday lighting. Every burned-out bulb, every flickering string, every frustrated hour spent troubleshooting represents a failure of preparation—not inevitability. The physics of thermal stress is predictable. The materials science behind embrittlement is well documented. And the prevention strategies—acclimation, sealing, proper hardware, and disciplined maintenance—are accessible, affordable, and highly effective. You don’t need to spend more on premium lights to succeed; you need to understand *how* and *why* they fail, then intervene at the precise points where cold does its damage. Start this season with one string treated to the full protocol: seal it, acclimate it, mount it right, and test it cold. Notice the difference. Then scale up. Your lights will last longer, your energy bill will stay steady, and your holiday spirit won’t be dimmed by technical frustration. Because the best decorations aren’t just beautiful—they’re resilient, responsible, and rooted in real-world wisdom.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?