Every holiday season, millions of homes are adorned with twinkling Christmas lights. But by mid-December, many families face the same frustrating issue: half the strand goes dark while the rest still glows. It’s not magic or bad luck—it’s electrical design. Understanding why entire sections of lights fail while others remain lit is key to avoiding the problem year after year.

The phenomenon of Christmas lights burning out in sections stems from how traditional incandescent light strings are wired—specifically in series circuits. When one bulb fails or becomes loose, it breaks the circuit for all bulbs downstream. Modern LED strands behave differently but can still suffer similar issues due to design choices made for cost and efficiency. This article explains the technical reasons behind partial light failure and offers actionable solutions to keep your display bright and reliable.

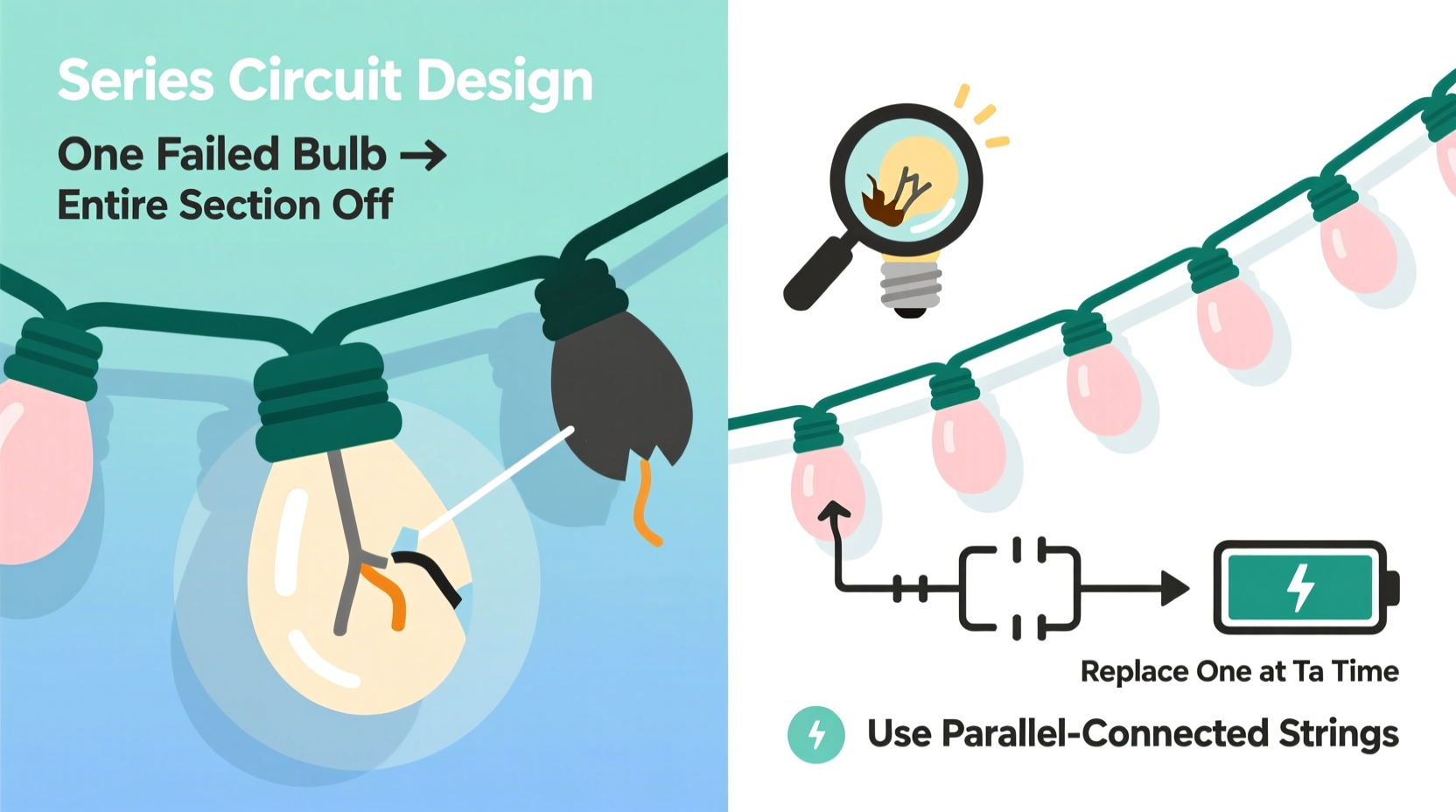

How Series Circuits Cause Sectional Burnouts

Most traditional Christmas light strings use a series circuit configuration. In this setup, electricity flows through each bulb in sequence before returning to the power source. If any single bulb burns out, loosens, or develops a poor connection, the circuit is broken, and current stops flowing beyond that point.

This is why you often see a strand where the first few bulbs work, but the rest are dark. The break occurs at the failed bulb, cutting off power to the remainder of the string. Some manufacturers divide longer strands into multiple parallel sections, each acting as its own series circuit. When one section fails, the others may continue working—giving the appearance of “sectional” burnout rather than total failure.

“Series wiring was adopted early on because it allowed lower-voltage bulbs to be used safely on standard 120V outlets. But it comes with reliability trade-offs.” — Dr. Alan Reeves, Electrical Engineer & Holiday Lighting Consultant

Each bulb in a typical 50-light incandescent strand receives about 2.4 volts (120V ÷ 50). If one filament breaks, the full voltage no longer distributes evenly, halting the flow. While newer designs incorporate shunts—tiny wires inside the bulb base meant to bypass a burned-out filament—these don’t always activate reliably, especially after repeated thermal cycling.

Differences Between Incandescent and LED Light Failures

LED Christmas lights have largely replaced incandescent models due to their energy efficiency and longevity. However, they’re not immune to sectional failures. The reason lies in how manufacturers replicate the familiar form factor while adapting to new technology.

Many LED strands still use series wiring within segments. For example, a 100-light LED string might be divided into five 20-light series sections wired in parallel. If one LED fails open-circuit (a common failure mode), only its 20-bulb segment will go dark. The rest stay lit because the parallel branches remain intact.

Unlike incandescent bulbs, LEDs rarely \"burn out\" from filament degradation. Instead, they typically fail due to:

– Overheating at the solder joint

– Voltage spikes from unregulated power sources

– Poor quality control in budget models

Some advanced LED strings use constant-current drivers and redundant pathways, minimizing the risk of cascading failure. But these are more expensive and less common in mass-market retail products.

Key Differences Summary

| Feature | Incandescent Lights | LED Lights |

|---|---|---|

| Wiring Type | Series (often segmented) | Series-parallel segments |

| Voltage per Bulb | ~2.4V (for 50-light strand) | Varies; often 3V per LED |

| Failure Mode | Filament break, shunt failure | Open circuit, driver failure |

| Lifespan | 1,000–3,000 hours | 25,000–50,000 hours |

| Energy Use | High (e.g., 20W per 50 lights) | Low (e.g., 2–4W per 100 lights) |

| Heat Output | Significant | Negligible |

Step-by-Step Guide to Diagnose and Fix Dead Sections

When part of your light strand goes dark, follow this systematic approach to identify and resolve the issue without replacing the entire string.

- Unplug the strand immediately. Safety first—never handle faulty wiring while energized.

- Inspect visually. Look for cracked bulbs, blackened sockets, or signs of melting. These indicate overheating or electrical arcing.

- Check connections between sections. If using modular strings, ensure plugs are fully seated. Corrosion or dirt can disrupt contact.

- Use a light tester or multimeter. Test each bulb in the dead section. Some testers automatically detect open filaments or failed shunts.

- Replace suspect bulbs one at a time. Start with visibly damaged ones. Use exact replacements (same voltage and base type).

- Test continuity in the socket chain. With a multimeter set to continuity mode, probe both contacts in the first non-working socket. No beep means an open circuit upstream.

- Reconnect and test. After replacement, plug in the strand briefly. If the section remains dark, repeat testing further up the line.

- Consider rewiring or retiring old strands. If multiple repairs are needed, consider upgrading to commercial-grade or shunt-free LED strings.

Prevention Strategies to Avoid Future Failures

Proactive maintenance extends the life of your lights and reduces seasonal frustration. Here are proven methods to minimize sectional burnouts:

- Choose lights with built-in shunt technology. Shunted bulbs are designed to maintain circuit continuity when the filament fails. Look for terms like “Stay-Lit” or “LightKeeper Pro compatible” on packaging.

- Invest in commercial-grade or prosumer strings. Higher-end models use thicker wire gauges, better insulation, and more durable sockets.

- Avoid daisy-chaining too many strands. Most manufacturers recommend no more than three to four connected strings. Exceeding this increases load and voltage drop, stressing components.

- Use surge-protected extension cords. Power surges during storms or grid fluctuations can damage sensitive LED drivers.

- Store lights properly off-season. Wrap them around a cardboard reel or use a dedicated light keeper spool. Avoid twisting or kinking, which damages internal wires.

- Label and organize by location. Knowing which strands go where helps rotate usage and retire aging sets before they fail mid-display.

Mini Case Study: The Neighborhood Nativity Display

In suburban Ohio, the Miller family has maintained a large outdoor nativity scene for over 15 years. Their display uses more than 2,000 lights across multiple trees, figures, and rooflines. Two years ago, they began experiencing frequent outages—sometimes losing entire sections mid-display.

After consulting a local electrician, they discovered two main causes: moisture ingress in poorly sealed connectors and excessive daisy-chaining (up to eight strands linked together). They upgraded to IP65-rated LED strings with molded, non-removable ends and installed individual GFCI-protected outlets for each major zone.

They also implemented a labeling system using colored zip ties and began rotating strands annually. As a result, their failure rate dropped from nearly 40% per season to under 5%. The display now runs reliably from Thanksgiving through early January with minimal intervention.

Essential Checklist for Long-Lasting Christmas Lights

Follow this checklist every season to maximize performance and lifespan:

- ✅ Inspect all strands for frayed wires, cracked sockets, or corrosion before installation

- ✅ Test each string individually before hanging

- ✅ Replace any flickering or dimming bulbs immediately

- ✅ Use weatherproof connectors and elevated outlet boxes outdoors

- ✅ Limit daisy-chaining to manufacturer specifications (usually 3–4 strands)

- ✅ Install on a timer to reduce daily runtime (6–8 hours often sufficient)

- ✅ Clean gently with a dry cloth after removal; avoid water immersion

- ✅ Store coiled loosely on reels or in compartmentalized bins

- ✅ Retire strands older than 5–7 years, even if functional

- ✅ Keep original packaging and manuals for warranty claims

Frequently Asked Questions

Can I mix LED and incandescent lights on the same circuit?

No, it’s not recommended. Mixing types can cause uneven voltage distribution, overheating, and premature failure. Additionally, their power draw and resistance differ significantly, increasing strain on shared connections. Always group similar technologies together and power them separately if possible.

Why do my new LED lights go out in sections if LEDs last so long?

While individual LEDs can last decades, the overall string design affects reliability. Many budget LED strands use series-wired segments to cut costs. A single failed diode or driver component can disable an entire section. Also, cheap capacitors or rectifiers in the plug end may degrade quickly under outdoor conditions, causing widespread failure despite robust LEDs.

Is there a way to fix a dead section without finding the bad bulb?

Yes, but with caveats. Devices like the LightKeeper Pro claim to restore continuity by sending a high-voltage pulse through the strand, potentially reactivating a failed shunt. However, success varies—especially with LED strings. Alternatively, you can bypass the dead section by cutting it out and rewiring the good ends, but this voids safety certifications and should only be done on low-voltage DC systems with proper knowledge.

Expert Insight: Design vs. Durability Trade-Offs

“The holiday lighting market prioritizes low upfront cost and ease of storage over longevity. That’s why we see so many fragile sockets and thin wires. Consumers expect lights to last just a few seasons—but with smarter design, they could easily last a decade.” — Maria Chen, Product Designer at Nordic Illumination Labs

Chen’s team focuses on modular, repairable light systems using standardized connectors and field-replaceable nodes. While currently niche, such designs represent the future of sustainable holiday decor. Until then, consumers must balance affordability with expectations for durability.

Conclusion: Shine Brighter with Smarter Habits

Sectional burnout in Christmas lights isn’t random—it’s a predictable outcome of electrical design choices made for economy and convenience. Whether you're decorating a small porch or managing a community display, understanding how your lights work empowers you to prevent failures before they happen.

By choosing better-quality strings, maintaining them carefully, and replacing aging sets proactively, you can enjoy consistent, reliable illumination year after year. The holidays are fleeting; your lights don’t have to be.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?