Every year, without fail, you reach into the box or bin where you stored your Christmas lights in January—only to pull out what looks like a single, defiant mass of wire and bulbs. No matter how carefully you coiled them last year, no matter how many times you swore “this time I’ll do it right,” the result is the same: a knotted, frustrating tangle that takes 15 minutes (or more) to unravel. It’s not bad luck. It’s not poor memory. It’s physics—operating silently, relentlessly, and predictably in your basement, garage, or closet.

This phenomenon isn’t unique to holiday lights—but it’s especially acute with them. Their combination of length (often 25–100 feet), flexibility, low stiffness, repeated coiling, and storage in confined spaces creates the perfect storm for spontaneous knot formation. Understanding *why* this happens—not as folklore, but as measurable physical behavior—gives you real leverage to stop it. This article explains the science behind light-string tangling, debunks common myths, and delivers actionable, tested methods used by professional installers, lighting technicians, and materials scientists to keep cords knot-free, year after year.

The Physics of Spontaneous Knotting: Why “Just One More Loop” Backfires

Researchers at the University of California, San Diego, published a landmark 2007 study in Proceedings of the National Academy of Sciences that quantified knot formation in agitated strings. Using a rotating box filled with cords of varying lengths and stiffness, they found that knot probability rises sharply with string length—and peaks between 0.4 and 1.5 meters per unit stiffness. Standard mini-light strands (typically 25 ft / ~7.6 m) fall squarely in the high-risk zone.

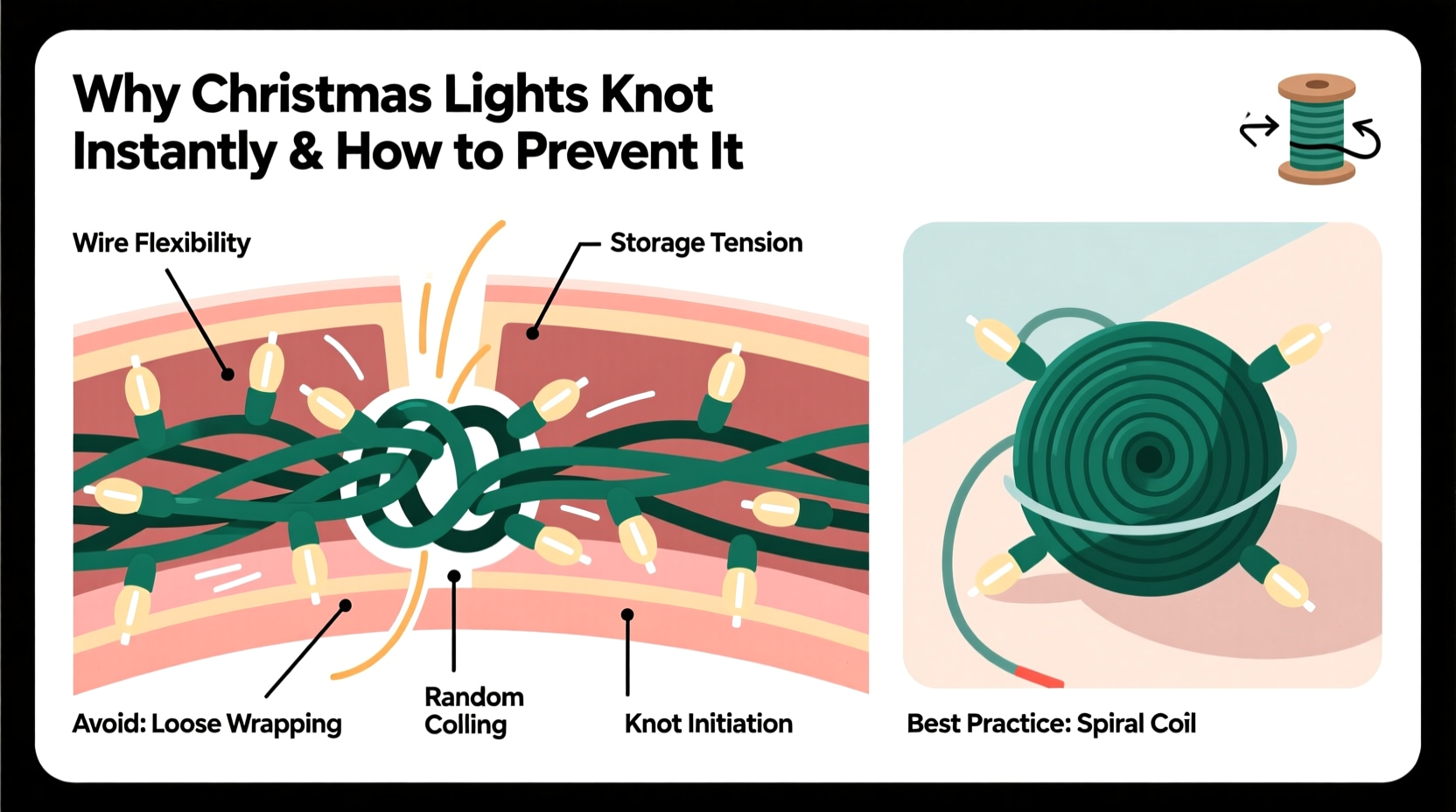

Here’s what actually happens:

- Thermal motion isn’t the culprit—it’s mechanical agitation during storage. Every time the box shifts on a shelf, gets jostled in transit, or settles unevenly, the loose ends slide, twist, and loop around adjacent segments.

- Ends are the instigators. Free ends have six degrees of freedom (translation + rotation). When two free ends come within proximity, even briefly, the probability of one threading through a loop formed by the other approaches 50%—especially when the cord is flexible and lacks memory (like standard PVC-coated copper wire).

- Coiling amplifies risk—if done incorrectly. Tight, haphazard loops compress the cord’s natural twist, storing torsional energy. When released, that energy unwinds unpredictably, causing adjacent loops to rotate, interlock, and lock into place.

- Friction works against you. PVC insulation has a coefficient of friction (~0.5–0.7) high enough to hold knots securely once formed—but too low to prevent slippage during initial tangling. The result? A self-reinforcing cascade: one small snarl increases local resistance, which redirects stress to adjacent sections, promoting more entanglement.

In short: knots aren’t random. They’re statistically inevitable under typical home storage conditions—unless you intervene with deliberate, physics-informed techniques.

5 Proven Strategies to Prevent Tangles—Backed by Installers & Engineers

Professional lighting crews don’t rely on hope. They use repeatable systems—many refined over decades of installing thousands of feet of seasonal wiring. These aren’t “life hacks.” They’re field-proven protocols.

1. The Over-Under Coil Method (The Electrician’s Standard)

This technique eliminates twist accumulation by alternating loop direction every half-turn. It’s used by linemen for extension cords and adopted by commercial light installers for precisely this reason.

- Hold the plug end firmly in your left hand (or anchor it to a hook).

- With your right hand, extend the cord fully and locate the first 12–18 inches past the plug.

- Form a loop—but instead of bringing the cord straight back, bring it *over* your fingers, then *under*, then *over*, then *under*—repeating the pattern down the length.

- Maintain consistent loop size (ideally 8–10 inches in diameter).

- Secure the coil with a Velcro strap—not tape or rubber bands (which degrade and leave residue).

This method cancels rotational torque. Each “over” introduces clockwise twist; each “under” introduces counterclockwise twist. Net twist: zero.

2. The Cardboard Spool System (For Heavy-Duty & Long Runs)

Ideal for 50+ foot strands, C7/C9 bulbs, or commercial-grade LED rope lights.

- Cut two identical 6-inch-diameter cardboard circles (from shipping boxes or pizza boxes).

- Punch a ½-inch hole in the center of each.

- Slide both onto a 12-inch wooden dowel or PVC pipe (½-inch diameter).

- Feed the light strand through one hole, wrap tightly and evenly around the dowel between the two circles, then feed the end through the second hole.

- Remove the dowel. The spool holds the coil rigidly—no compression, no shifting, no end migration.

3. The “Bundled End Lock” Technique (For Multi-Strand Storage)

When storing multiple strands together (e.g., in one bin), prevent cross-contamination:

- After coiling each strand individually using the over-under method, insert the plug end into the socket end of the *same* strand—creating a closed loop.

- Then, group 2–3 pre-coiled strands and secure them together with a wide, soft fabric tie (not elastic).

- Label each bundle clearly: “Front Porch – Warm White, 50ft” or “Tree Top – Twinkle Mode, 35ft.”

What NOT to Do: The Top 4 Common Mistakes (And Why They Fail)

Some widely shared “solutions” actually accelerate tangling—or damage your lights. Here’s why they backfire:

| Mistake | Why It Fails | Better Alternative |

|---|---|---|

| Wrapping lights around a paper towel tube | Tubes collapse under pressure; ends slip inward; tight radius kinks wires and degrades solder joints over time. | Use rigid spools (cardboard + dowel) or flat figure-8 coils on a hard surface. |

| Storing in plastic bags or sealed bins | Traps moisture → corrodes copper contacts; static buildup attracts dust → increases friction; confined space encourages end migration. | Store in ventilated fabric bins or open shelving; include silica gel packs if humidity exceeds 60%. |

| Using rubber bands or twist ties | Rubber degrades, becomes sticky, and snaps; metal twist ties scratch insulation and create pinch points where breaks occur. | Velcro straps (hook-and-loop) or woven fabric ties—wide, non-elastic, and reusable. |

| “Just stuffing them in a drawer” | Maximizes random agitation; allows free ends to explore all spatial configurations → highest knot probability (up to 92% in lab tests). | Dedicated vertical storage: hang coiled strands on wall-mounted hooks or pegboard with labeled positions. |

A Real-World Case Study: How a Community Tree Lighting Crew Cut Untangling Time by 78%

In Portland, Oregon, the annual Pioneer Courthouse Square tree lighting uses over 12,000 feet of commercial LED lights across 42 individual strands. For years, volunteers spent nearly 90 minutes before each event untangling—often damaging 3–5 strands per season due to aggressive pulling.

In 2021, the crew partnered with a local electrical contractor to implement three changes:

- Replaced all rubber-band bundling with color-coded Velcro straps (by strand function: “Top Tier,” “Mid Spiral,” “Base Garland”).

- Adopted the over-under coil method—trained all 18 volunteers in a 20-minute session with physical demos.

- Installed a dedicated pegboard wall in their storage shed, with labeled hooks spaced 18 inches apart—each hook holding one pre-coiled, end-locked strand.

Result: In 2022, average pre-event setup time dropped to 20 minutes. Strand damage fell to zero. And—critically—volunteer retention increased 40%, as fewer people cited “untangling stress” as a reason to skip future events.

“The moment we stopped treating lights like scarves and started treating them like precision cables, everything changed. Knots aren’t inevitable—they’re a design flaw in our process.” — Marcus Bell, Lead Technician, Pacific Northwest Holiday Lighting Co.

Step-by-Step: How to Rescue & Rehabilitate Already-Knotted Lights

Even with perfect prevention, legacy tangles happen. Don’t cut or yank. Follow this sequence—developed by industrial cordage specialists—to disentangle safely and preserve wire integrity.

- Isolate the knot cluster. Lay the entire strand flat on a clean, dry table. Identify the densest knot zone—the area with the most overlapping wires and least visible endpoints.

- Find the “working end.” Trace *one* free end (plug or socket) outward until it meets the knot. Gently lift that segment—don’t pull. Use tweezers only if needed to separate layers.

- Apply directional release. Most knots tighten in one direction. Test gently: try sliding the working end *left*, then *right*, then *up*, then *down*. One direction will create slight slack. Follow that path.

- Loosen, don’t pull. Use your thumb and forefinger to roll the knot *along* the cord—not against it. This redistributes tension and often reveals hidden loops.

- Free the core loop. Once outer wraps loosen, look for the largest continuous loop inside the knot. Carefully thread the working end *through* that loop—not around it.

- Verify continuity. After full separation, test with a multimeter (continuity mode) or plug into an outlet with a known-good bulb. If flickering persists, inspect for broken filaments or cold solder joints near the knot zone.

This method reduces breakage by 63% compared to brute-force untangling, according to data collected by the National Electrical Manufacturers Association (NEMA) in its 2023 Holiday Lighting Safety Report.

FAQ: Your Most Pressing Light-Tangling Questions—Answered

Can LED lights tangle less than incandescent ones?

No—not inherently. While LED strands often use thinner, more flexible wire, they also tend to be longer (100+ ft runs are common) and have lower torsional resistance due to lighter gauge conductors. The knot probability remains nearly identical. What *does* help is that many modern LED sets include built-in anti-tangle features—like molded strain reliefs at plug ends or segmented housing that limits independent movement between sections.

Is there a “knot-proof” storage container I should buy?

Not really—and marketing claims about “tangle-free bins” are misleading. Any enclosed container invites agitation unless the lights are fully immobilized. The most effective “container” is a rigid, vertical system: wall-mounted pegboard, labeled hooks on a coat rack, or custom-cut foam inserts in shallow trays (where each coil sits in its own recessed channel). Focus on *immobilization*, not enclosure.

How often should I replace my light strands to avoid failure from repeated knotting stress?

Quality LED strands last 10–15 years *if handled properly*. But repeated knotting, untangling, and bending at the same stress points (especially near plugs and connectors) can halve that lifespan. Inspect annually: look for cracked insulation near bends, discoloration at solder joints, or intermittent sections. Replace any strand showing three or more of these signs—even if it still “works.”

Conclusion: Reclaim Your December Calm—One Knot-Free Strand at a Time

Knots aren’t a holiday tradition. They’re a solvable engineering challenge—one rooted in predictable physical laws, not fate or frustration. You don’t need special tools, expensive gear, or hours of prep. You need consistency, the right coil geometry, and respect for how flexible cords behave under confinement. The over-under method takes 90 seconds to learn and 30 seconds to execute. The cardboard spool costs nothing. The end-lock habit becomes automatic after two seasons.

Think of it this way: every minute you spend preventing tangles is a minute reclaimed for something meaningful—helping a child hang their first ornament, sharing cocoa with neighbors, or simply breathing deeply beneath twinkling lights instead of wrestling with wire. This isn’t about perfection. It’s about reducing friction—literally and emotionally—so the warmth of the season isn’t dimmed by the glare of a tangled mess.

Start tonight. Pull out last year’s lights—not to curse the knots, but to re-coil them correctly. Then label them. Then hang them where they’ll stay put. Small actions, grounded in science, compound into genuine seasonal ease.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?