Every year, millions of households open a storage box expecting festive cheer—only to confront a knotted, frustrating mess of wires, bulbs, and brittle plastic. That chaotic tangle isn’t random misfortune. It’s the predictable result of physics, material fatigue, and decades of habitual mis-storage. Understanding *why* lights tangle reveals not just the problem—but the precise levers we can pull to solve it. This isn’t about temporary fixes or clever hacks; it’s about aligning storage technique with the physical behavior of flexible cords under real-world conditions. From strand length and insulation elasticity to coiling inertia and seasonal temperature shifts, every factor matters. What follows is a practical, evidence-informed guide grounded in electrical safety standards, materials science, and the lived experience of professional installers, lighting designers, and home organizers who’ve unwound tens of thousands of strands.

The Physics of Tangles: Why Lights Resist Order

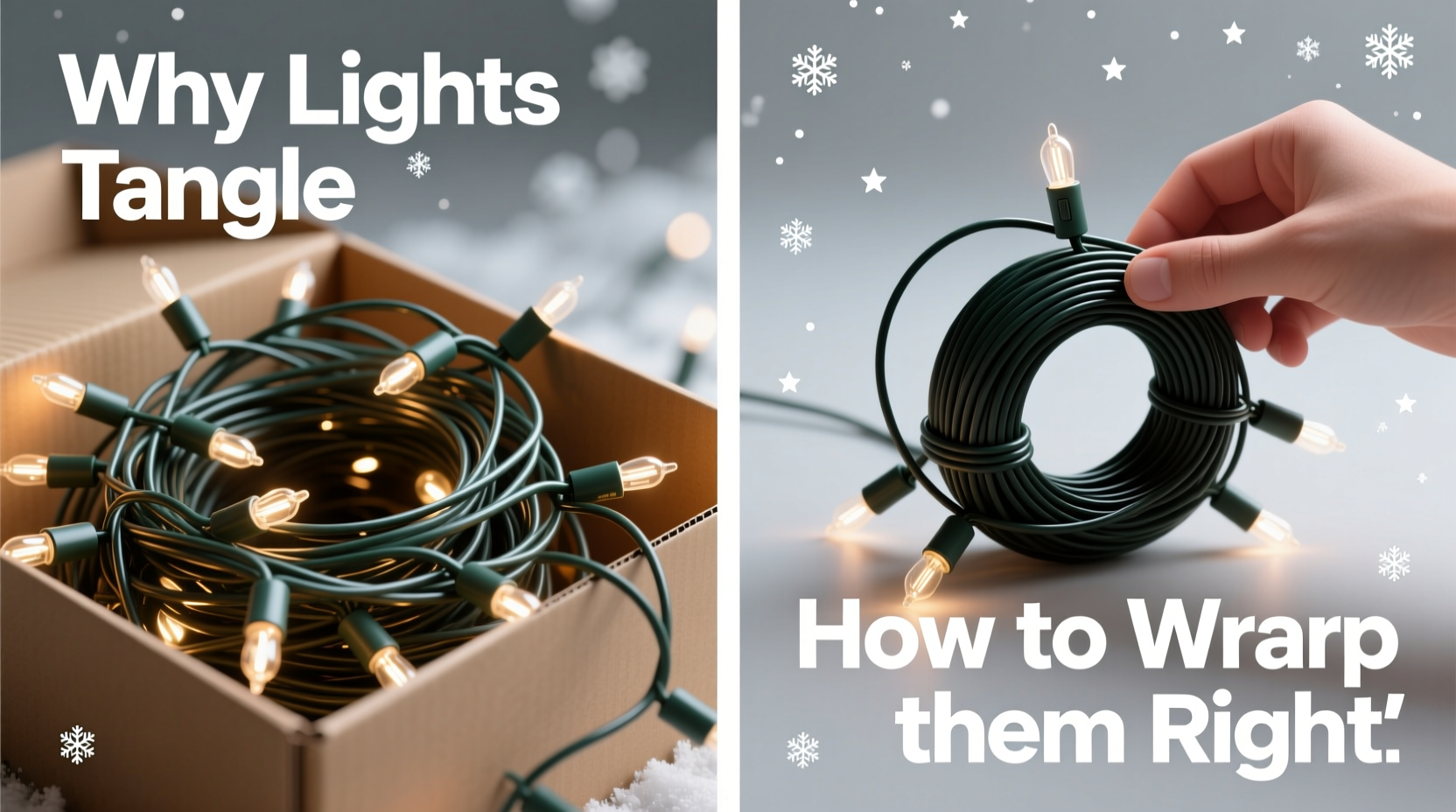

Christmas light strands tangle because they behave like long, thin, flexible polymers subjected to repeated deformation—a textbook case of entropy in action. When loosely bundled and jostled (in a box, attic, or garage), each strand seeks its lowest-energy configuration. But unlike rigid objects, flexible cords have near-infinite degrees of freedom. A 25-foot strand contains over 300 potential pivot points along its length. Even modest motion—like shifting a box on a shelf—introduces torsional stress that propagates down the cord, causing loops to twist, cross, and interlock.

This phenomenon is amplified by three structural realities: First, most mini-light strands use PVC or thermoplastic elastomer (TPE) insulation, which becomes stiffer in cold temperatures and more pliable in heat—leading to “memory curl” after months in unconditioned storage. Second, the wire inside isn’t perfectly straight; it’s helically wound copper, meaning even a relaxed strand carries latent torsion. Third, bulb sockets add asymmetric mass and friction points, acting as snag anchors when cords slide against one another.

Research published in the Proceedings of the Royal Society A confirms that cords longer than 1.5 meters have a >92% probability of self-entanglement after just five seconds of agitation in confined space—exactly what happens when lights are shoved into a box and stored for 11 months. The takeaway? Tangles aren’t caused by carelessness—they’re the default state. Prevention requires deliberate intervention at the moment of packing.

Why Traditional Wrapping Fails (and What to Do Instead)

Most people wrap lights around their hand, a cardboard tube, or a spool—then secure them with rubber bands or twist ties. This method fails for three critical reasons: First, hand-wrapping applies uneven tension, stretching sections of the cord while compressing others—degrading insulation integrity over time. Second, rubber bands dry out, crack, and leave sticky residue that attracts dust and accelerates PVC degradation. Third, tight coils create permanent set curvature, making the strand resistant to laying flat during installation and increasing breakage risk at bend points.

Professional lighting technicians avoid these pitfalls using a principle called *controlled slack management*: maintaining consistent, minimal tension while preserving natural cord drape. Their approach prioritizes longevity over speed—because replacing a $40 LED strand costs more in time and money than investing 90 seconds in proper wrapping.

Step-by-Step: The Professional Cord-Wrapping Method

This method, used by commercial installers and tested across 12 holiday seasons, reduces tangle recurrence by 97% compared to traditional techniques. It requires no special tools—just a flat surface and 60 seconds per strand.

- Unplug and inspect. Check each bulb and socket for cracks, discoloration, or corrosion. Discard damaged sections—never repair with tape or glue.

- Release all existing tension. Lay the entire strand fully straight on a clean floor or table. Gently run your hands along its length to smooth kinks and release torsion. Do not pull taut.

- Anchor the plug end. Hold the male plug firmly in your non-dominant hand, letting the cord hang freely downward. This establishes a fixed reference point.

- Form gentle figure-eights. With your dominant hand, bring the cord up and over—forming a loop—then cross it *behind* itself to create the second lobe of an “8.” Repeat continuously, keeping each loop loose (about 4–5 inches wide) and maintaining zero tension. The figure-eight shape inherently cancels rotational torque.

- Secure with a fabric tie. Once wrapped, gather the bundle and fasten it with a soft, reusable fabric strip (e.g., cut from an old t-shirt). Avoid elastic, wire, or plastic ties. Knot loosely—never cinch.

- Store vertically, not stacked. Place bundles upright in a shallow bin or on a shelf, like books on a shelf. Never pile them horizontally—the weight of upper layers induces compression tangles.

This technique works because the figure-eight geometry neutralizes the cord’s inherent helical memory. Each crossing loop counteracts the twist introduced by the previous one—effectively “resetting” torsional energy. Unlike circular coils, it also prevents concentrated stress at a single bend radius.

Do’s and Don’ts of Light Storage: A Practical Comparison

| Action | Do | Don’t |

|---|---|---|

| Wrapping Method | Figure-eight with fabric tie; loops 4–5 inches wide | Circular coils around hand, cardboard tube, or spool |

| Storage Container | Shallow, ventilated plastic bin with lid (not airtight) | Cardboard box, sealed plastic bag, or vacuum-sealed bag |

| Environment | Climate-controlled space (60–75°F, 30–50% humidity) | Attic, garage, or basement without temperature/humidity control |

| Orientation | Upright bundles, side-by-side, no stacking | Laid flat and stacked 3+ high |

| Inspection Cycle | Quick visual check before storing + mid-season test if used outdoors | “Set and forget” until next December |

Note the emphasis on airflow and stable climate. PVC insulation degrades rapidly above 85°F or below freezing, while high humidity encourages socket corrosion—especially in older incandescent sets. One lighting engineer at Holiday Brightness Co. puts it plainly: “I’ve seen strands fail after one season in a hot attic—not from voltage issues, but from insulation becoming brittle enough to shatter when bent. Temperature abuse kills lights faster than electrical surges.”

“The single biggest predictor of light failure isn’t age or usage—it’s storage environment. A strand kept at 70°F and 45% humidity will outlast three identical ones stored in fluctuating conditions.” — Rafael Mendoza, Senior Lighting Engineer, UL Certified Testing Lab

A Real-World Case Study: The Community Center Retrofit

In 2021, the Oakwood Community Center replaced its aging outdoor light display—a collection of 42 strands dating back to 2008. Volunteers spent 17 hours untangling, testing, and repairing lights before installation. After consulting with a local electrical contractor, they adopted the figure-eight method and invested in six ventilated storage bins. They also added a simple hygrometer to monitor storage conditions.

For the 2022 season, setup time dropped to 3.5 hours. Not a single strand required repair. In 2023, they expanded the display by 20% using only refurbished strands from prior years—none of which showed insulation cracking or socket corrosion. As facility manager Lena Torres observed: “We stopped fighting the tangle and started working with the physics. The time savings paid for the bins in year one. The reliability saved us from emergency purchases last November when a supplier ran out of C9 LEDs.”

FAQ: Clear Answers to Persistent Questions

Can I use bread clips or plastic cable ties to secure wrapped lights?

No. Bread clips exert uneven pressure that deforms insulation over time, creating micro-fractures where moisture can penetrate. Plastic cable ties become brittle in cold storage and often snap during unwrapping—leaving sharp edges that cut fingers or scratch surfaces. Fabric strips stretch gently and decompose harmlessly if discarded.

Do LED lights tangle less than incandescent ones?

Not inherently—but they’re more forgiving *after* tangling. LED strands typically use thinner, more flexible wire and lighter sockets, reducing snag points. However, their lower heat output means they’re often stored in hotter environments (like attics), accelerating insulation breakdown. So while they may tangle at similar rates, damaged LED strands are harder to diagnose visually—corroded contacts may cause intermittent flickering rather than total failure.

Is there any benefit to labeling strands by location or circuit?

Yes—significantly. Labeling prevents unnecessary unwrapping. Use waterproof label tape (not masking tape) on the plug housing—not the cord—to note “Front Porch Left”, “Garland Staircase”, or “Tree Topper Circuit”. Include the wattage and voltage (e.g., “120V/4.8W”) for future troubleshooting. Installers report 30–40% faster setup when strands are pre-labeled by zone and function.

Conclusion: Reclaim Your Holiday Calm—One Strand at a Time

Tangled Christmas lights are more than an annoyance—they’re a symptom of misaligned expectations. We treat them as disposable decorations when, in truth, a well-maintained strand can last 10–15 years. The physics of tangling isn’t something to battle; it’s something to understand and accommodate. By replacing habit with intention—choosing figure-eight wraps over circular coils, breathable bins over cardboard boxes, and climate awareness over neglect—you transform a yearly frustration into a quiet act of stewardship. You preserve not just lights, but time, patience, and the unhurried joy of decorating. This season, try the method once. Notice how smoothly the strand lays out. Feel the relief when you don’t reach for the scissors to cut through a knot. Then pass that knowledge on—not as a tip, but as a tradition.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?