Every year, as families gather to string up festive lights, a familiar frustration emerges: one bulb flickers out, and suddenly the entire strand goes dark. Even worse, sometimes an entire section of lights fails simultaneously—leaving puzzled homeowners wondering if faulty wiring, poor craftsmanship, or something more technical is to blame. The answer lies not in bad luck but in the fundamental electrical design of traditional Christmas light strands. Understanding the science behind this phenomenon reveals how circuit structure, voltage distribution, and material fatigue contribute to synchronized failures—and what you can do to prevent them.

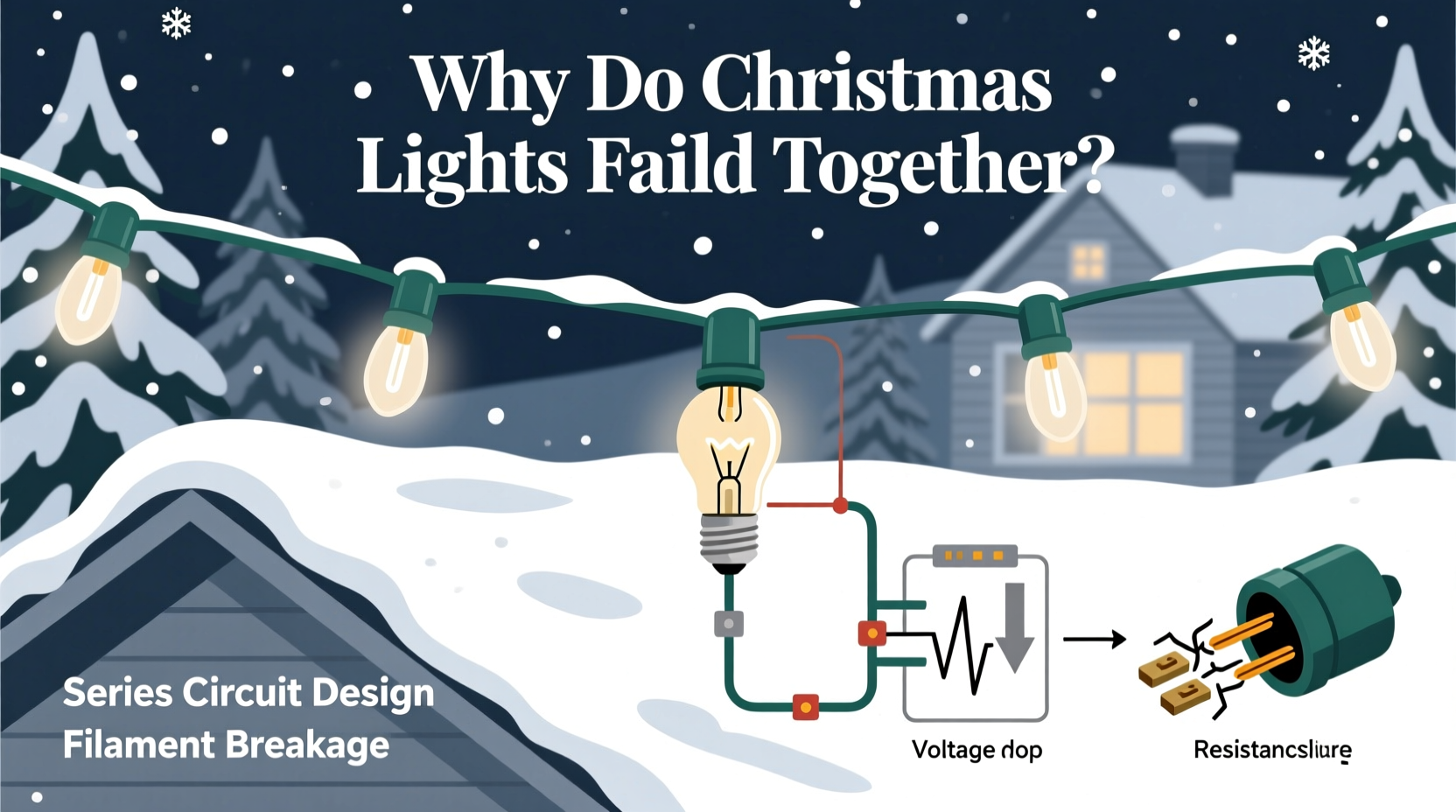

The Series Circuit Problem

Most older and budget-friendly Christmas light sets are wired in series, meaning each bulb is connected along a single continuous path for electricity. In this configuration, current must flow through every single bulb to complete the circuit. If one bulb burns out or becomes loose, the circuit breaks, and the entire strand shuts off. This explains why one failed bulb can take down dozens of others—but it doesn’t fully explain why multiple bulbs might fail at once.

In a series circuit, the total voltage from the power source (usually 120V in U.S. households) is divided evenly across all bulbs. For example, a strand of 50 mini-bulbs splits 120 volts into approximately 2.4 volts per bulb. While efficient for low-voltage components, this setup creates a delicate balance. Any fluctuation—such as a brief power surge, overheating, or manufacturing inconsistency—can cause several bulbs to exceed their tolerance at nearly the same time.

Voltage Stress and Thermal Fatigue

One reason multiple bulbs fail together is due to thermal cycling—the repeated expansion and contraction of metal filaments as lights turn on and off. Each time the strand is powered, the tungsten filament heats rapidly to over 2,000°C, then cools when switched off. Over time, this weakens the metal, especially at thin or imperfect points.

Because all bulbs in a series experience identical on/off cycles, they age at roughly the same rate. After 3–5 holiday seasons, many filaments reach their breaking point within days or weeks of each other. This synchronized degradation leads to clusters of failures that appear simultaneous, even though they occur slightly apart.

Additionally, slight variations in filament thickness during manufacturing mean some bulbs carry marginally higher current than others. These \"weak links\" heat up faster and degrade sooner. Once one fails, the full voltage redistributes across the remaining bulbs—increasing stress on those still working and accelerating further failures in a cascading effect.

“Series-wired holiday lights operate under shared electrical stress. When one component fails, the rest face increased load, making chain reactions common.” — Dr. Alan Reeves, Electrical Systems Engineer, MIT Lincoln Laboratory

Modern Designs and Shunt Technology

To combat mass failures, many modern mini-light strands include shunts—tiny bypass wires embedded in each bulb’s base. When a filament breaks, the shunt activates due to a surge in voltage, creating an alternative path for current so the rest of the strand stays lit. This innovation significantly improves reliability.

However, shunts aren't foolproof. They require a high enough voltage spike to melt a coating and close the circuit. In low-current conditions or with degraded contacts, the shunt may not activate. Moreover, while shunts keep the light on, the dead bulb remains nonfunctional. Over successive seasons, accumulated inactive bulbs increase resistance and reduce brightness, eventually leading to noticeable dimming or complete failure when too much load builds up.

Another advancement is parallel-wired strings, where each bulb has its own connection to the main line. These are far more reliable because individual bulb failure doesn’t affect others. However, they’re typically more expensive and less common in standard consumer strands due to higher material and production costs.

Environmental and Usage Factors

Beyond circuit design, external conditions play a major role in synchronized burnout. Outdoor lights face temperature swings, moisture, and UV exposure—all of which degrade insulation, corrode connections, and weaken solder joints. A cold snap following a warm day can crack plastic housings; humidity can lead to internal condensation and short circuits.

Improper storage also contributes. Tightly coiled lights stored in hot attics or damp basements develop stress fractures in wires and connectors. When reused, these micro-damages become points of failure under electrical load. Because adjacent bulbs may share compromised sections of wire or sockets, their failure timing aligns—not due to electrical design alone, but mechanical wear.

Overloading circuits by connecting too many strands together exacerbates the issue. Most manufacturers recommend no more than three or four strands daisy-chained. Exceeding this limit increases amperage beyond safe levels, generating excess heat that accelerates filament fatigue across multiple units simultaneously.

| Factor | Effect on Lights | Prevention Strategy |

|---|---|---|

| Series Wiring | Single failure breaks entire circuit | Use shunted bulbs or switch to parallel designs |

| Thermal Cycling | Filament fatigue over time | Limit daily on/off cycles; use timers |

| Power Surges | Sudden voltage spikes damage filaments | Plug into surge protectors |

| Poor Storage | Wire cracks, socket deformation | Store loosely wound in climate-controlled space |

| Daisy-Chaining Too Many Strands | Overheating and voltage drop | Follow manufacturer limits; use separate outlets |

Step-by-Step Guide to Diagnosing and Preventing Mass Failure

Understanding the root causes is only half the battle. Applying preventive measures ensures longer-lasting displays and fewer mid-season disappointments.

- Inspect Before Hanging: Test new and stored strands before installation. Use a light tester or plug them in temporarily to catch early signs of flickering or dead sections.

- Replace Bulbs Promptly: At the first sign of a dark bulb, replace it—even if the strand still works. Delaying replacement increases strain on remaining bulbs.

- Use Surge Protectors: Plug light circuits into surge-protected outlets, especially for outdoor setups vulnerable to weather-related surges.

- Avoid Daisy-Chaining Excessively: Never connect more than three or four strands unless explicitly rated for longer runs. Check packaging labels for specifications.

- Install Timers: Set lights to run only during evening hours. Reducing operational time minimizes thermal cycling and extends lifespan.

- Store Properly: Wrap lights around cardboard reels or use specialized spools. Avoid folding sharply or compressing tightly, which damages internal wires.

- Upgrade Gradually: Replace aging strands with LED-based, parallel-wired models. Though initially more costly, they consume less energy and last significantly longer.

Real-World Example: The Johnson Family Display

The Johnsons in suburban Ohio have maintained a large front-yard Christmas display for over 15 years. Each November, they retrieve hundreds of feet of multicolored mini-lights from storage—only to find that nearly half fail within the first week of December. Initially blaming cheap brands, they began tracking patterns and discovered a consistent trend: the oldest strands, stored in the garage attic, always failed together, regardless of brand.

After consulting an electrician, they realized two issues: extreme summer heat in the attic had warped sockets and degraded insulation, and they were routinely linking six to eight strands together—tripling the intended load. By switching to labeled “connectable up to 4” strands, using surge-protected timers, and storing lights in sealed bins inside the house, their failure rate dropped by over 80%. Their biggest insight? Synchronized failure wasn’t random—it was predictable based on usage history and environmental exposure.

LEDs vs. Incandescent: A Lifespan Comparison

The shift from incandescent to LED Christmas lights has dramatically reduced simultaneous failures. LEDs don’t rely on fragile filaments; instead, they use semiconductor junctions that emit light when current passes through. This makes them inherently more durable against vibration, cycling, and minor surges.

Moreover, most LED strands are wired in series-parallel configurations—groups of LEDs in series, then those groups connected in parallel. This hybrid design limits the impact of a single failure to a small segment rather than the whole string. Combined with lower operating temperatures and minimal power draw, LEDs can last 25,000 to 50,000 hours compared to 2,000–3,000 for incandescent bulbs.

FAQ

Why do only half my string go out?

This usually indicates a partial circuit break. In multi-circuit strands (common in wide-angle or dual-wave sets), each half operates independently. One failed bulb or loose connection in a series section will kill that half while the other remains lit.

Can I mix different types of bulbs in one strand?

No. Mixing wattages or bulb types alters current flow and can overload sockets or cause premature burnout. Always use replacement bulbs with identical voltage and amperage ratings.

Are there tools to find a single bad bulb quickly?

Yes. Non-contact voltage testers and dedicated light-checker wands can scan along a strand and detect where current stops flowing, pinpointing the location of a broken filament without removing each bulb.

Final Recommendations and Call to Action

The seemingly mysterious tendency of Christmas lights to fail en masse is rooted in well-understood electrical principles. From series circuit limitations to cumulative thermal stress, the reasons are both technical and practical. But armed with this knowledge, you’re no longer at the mercy of darkened strands and holiday frustration.

Start by auditing your current collection: retire old incandescent sets showing frequent failures, upgrade to quality LED alternatives, and implement smart habits like surge protection and proper storage. Small changes today can preserve your lights for years, saving money, reducing waste, and ensuring your holiday display shines brightly season after season.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?