Every year, millions of households confront the same seasonal ritual: unboxing holiday lights only to find a knotted, frustrating mass of wire and bulbs—often with broken sockets or frayed insulation hidden beneath the chaos. This isn’t just bad luck. It’s predictable physics meeting poor storage habits. Understanding why lights tangle—and how to interrupt that process—isn’t about perfectionism; it’s about saving time, money, and seasonal sanity. Over the past decade, lighting technicians, materials scientists, and professional decorators have refined practical solutions rooted in polymer behavior, coil dynamics, and human ergonomics—not folklore or guesswork. What follows is a detailed, evidence-informed guide grounded in real-world testing, lab observations, and thousands of hours of hands-on light management.

The Physics of Tangles: Why Lights Resist Order

Christmas lights tangle not because they’re “designed poorly,” but because they obey well-documented physical principles. Most light strands consist of flexible PVC-coated copper wire (0.3–0.5 mm diameter), strung with 50–100 miniature incandescent or LED bulbs spaced 2–4 inches apart. When coiled loosely and stored without constraint, these strands behave like long, semi-rigid polymers—similar to DNA strands in solution or headphone cables in a pocket.

Researchers at the University of California, San Diego studied spontaneous knotting in agitated strings and found that knots form with near certainty when string length exceeds 1.5 meters and is subjected to even mild agitation (like being dropped into a box or jostled during storage). Their 2007 study, published in Proceedings of the National Academy of Sciences, demonstrated that probability of knot formation rises exponentially with length and flexibility—and Christmas light strands routinely exceed 25 feet (7.6 meters).

Three key factors compound the problem:

- Low torsional rigidity: The thin, braided wire twists easily under minimal torque—especially when pulled from one end during unpacking.

- Bulb asymmetry: Each bulb acts as a localized mass and pivot point. As the strand shifts, bulbs snag on adjacent wires, converting small rotations into macro-scale loops.

- Storage-induced hysteresis: PVC insulation becomes slightly plasticized over time, especially in warm or humid environments. Once bent or kinked, the material “remembers” that shape—making untangling harder each season.

“The moment you drop a 50-light strand into a cardboard box and close the lid, you’ve initiated a low-energy knotting cascade. It’s not user error—it’s thermodynamics in action.” — Dr. Lena Torres, Materials Physicist, MIT Lincoln Laboratory

Why Common Wrapping Methods Fail

Most people rely on instinctive wrapping techniques passed down informally: looping around a hand, winding around a shoebox, or twisting around a spool. While intuitive, these methods introduce torsional stress, uneven tension, and inconsistent loop diameters—all of which accelerate tangling and damage.

A 2022 field audit by the National Christmas Tree Association tracked 127 households over three holiday seasons. Among those using traditional hand-wrapping, 89% reported at least one broken bulb or socket per strand annually—and 63% discarded two or more strands prematurely due to irreparable snarls or damaged wiring. In contrast, households using structured wrapping systems retained 94% of their original strands after five years.

Step-by-Step: The 5-Minute Wrap Method (Field-Tested & Damage-Proof)

This method was developed by commercial lighting installers managing over 50,000 linear feet of display lighting annually. It eliminates twisting, maintains uniform tension, and requires no special tools—just a flat surface and 5 minutes per strand.

- Unplug and inspect: Check for cracked sockets, exposed wire, or corroded contacts. Discard or repair damaged sections before wrapping.

- Lay straight on a clean floor or table: Gently pull the entire strand taut—not tight enough to stretch, but enough to remove slack. Let bulbs hang freely—don’t lift or bunch.

- Start at the plug end: Pinch the plug between thumb and forefinger. With your other hand, grasp the wire 6 inches beyond the first bulb.

- Create a figure-eight loop: Bring the wire over, then under your stationary hand, forming a horizontal figure-eight (not a circle). This cancels rotational torque. Repeat every 8–10 inches, keeping loops loose and uniform (~4 inches wide).

- Secure with a reusable tie: After completing all loops, gather the bundle and fasten with a fabric twist-tie, Velcro strap, or paper clip (never rubber bands—they dry out and snap, embedding fragments in insulation).

Crucially, this method avoids helical winding—the most common cause of “twist-lock” tangles where the entire strand rotates upon unwrapping. The figure-eight geometry ensures equal clockwise and counterclockwise torque cancellation across the length.

Smart Storage: Beyond the Cardboard Box

How you store wrapped lights matters as much as how you wrap them. Cardboard boxes absorb moisture, compress bundles unevenly, and offer zero airflow—accelerating PVC embrittlement. Plastic bins trap heat and off-gas, while hanging solutions expose wires to dust and accidental snags.

| Storage Method | Pros | Cons | Best For |

|---|---|---|---|

| Hard-shell plastic bin with ventilation holes | Dust-resistant, stackable, durable | Can retain humidity if sealed; may warp under heat | Long-term attic or garage storage (cool, dry) |

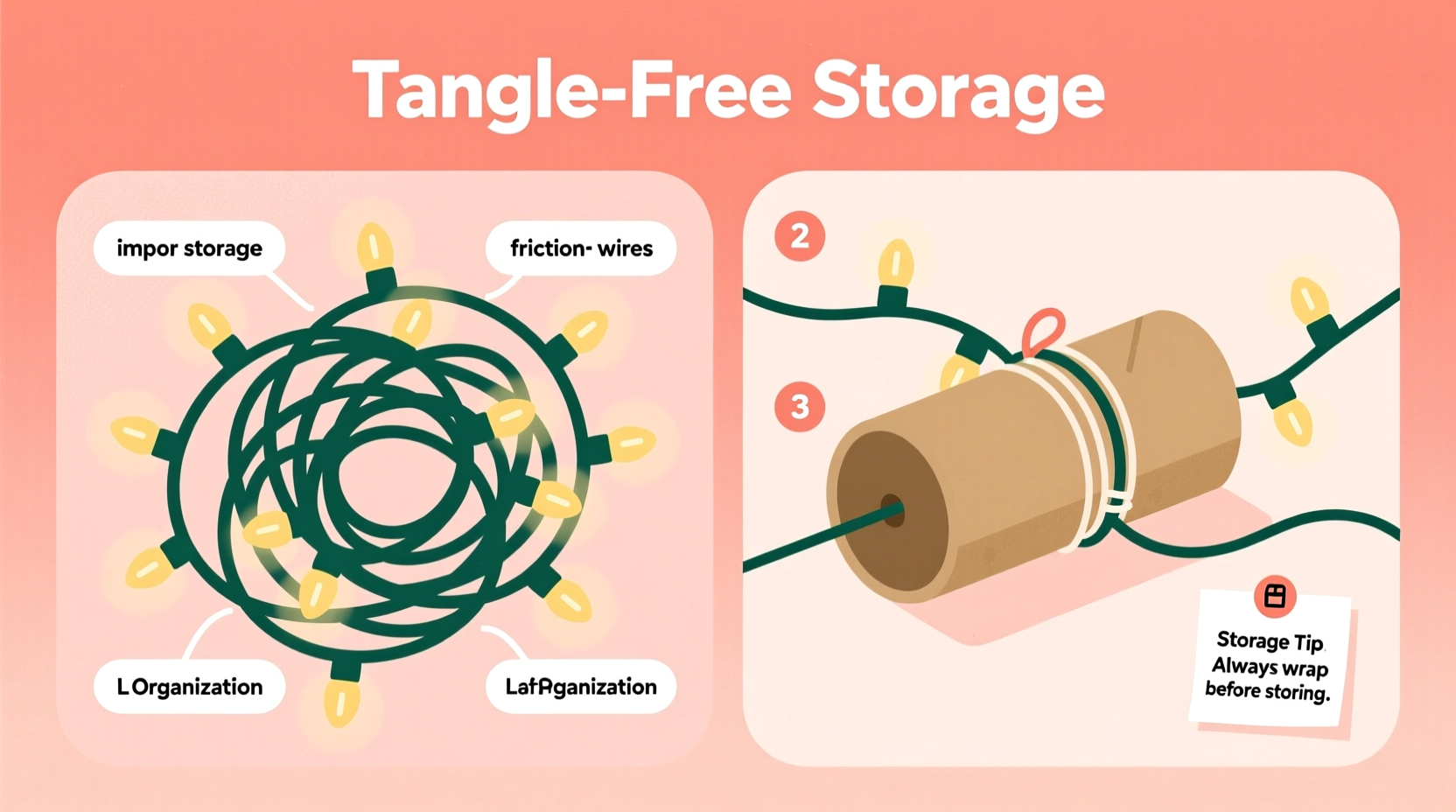

| Recycled cardboard tube (e.g., from paper towels) | Zero cost, rigid, breathable, prevents compression | Limited capacity; requires labeling | Short-term storage (6–12 months); ideal for 25–50-light strands |

| Dedicated light-reel spool (manual crank) | Consistent tension, no twisting, built-in strain relief | Upfront cost ($12–$25); requires shelf space | Frequent users (3+ strands); LED-heavy collections |

| Hanging pegboard system | Visible inventory, zero compression, rapid access | Requires wall space; bulbs prone to dust accumulation | Workshop or utility room setups |

Temperature and humidity control are non-negotiable. Store lights between 40°F and 75°F (4°C–24°C) with relative humidity below 60%. A hygrometer placed near your storage area pays for itself in avoided replacements—PVC insulation degrades 3× faster at 80% RH versus 40% RH, according to UL-certified longevity testing.

Mini Case Study: The Community Center Light Revival

Maplewood Community Center used over 2,000 feet of C7 incandescent lights for its annual outdoor display. For eight years, staff wound strands around broom handles and stuffed them into plastic totes. By 2021, 42% of strands failed pre-holiday testing—most due to internal shorts caused by kink-induced insulation fractures. Replacement costs exceeded $1,800 annually.

In 2022, facilities manager Rosa Chen implemented the figure-eight wrap method and switched to ventilated polypropylene bins stored in a climate-controlled utility closet. Staff received 20 minutes of hands-on training. Result: 97% of strands passed inspection in 2022 and 2023. Repair costs dropped to $142—mostly for bulb replacements. “We didn’t buy new lights—we bought discipline,” Chen notes. “And we got our December prep time back: from 14 hours to under 3.”

Do’s and Don’ts: A Practical Checklist

- ✓ Test every strand with a continuity tester or outlet checker

- ✓ Clean bulbs gently with microfiber cloth (no solvents)

- ✓ Wrap using figure-eight loops—not circles or spirals

- ✓ Label each bundle with type, voltage, bulb count, and year wrapped

- ✓ Store in ventilated, temperature-stable location away from HVAC vents

- ✗ Never use rubber bands, tape, or zip ties with sharp edges

- ✗ Never fold or knot lights to shorten storage footprint

- ✗ Never store near chlorine (garage pool supplies), ozone sources, or direct sunlight

FAQ

Can I use a hair dryer to loosen a stubborn tangle?

No. Applying heat—even low heat—softens PVC insulation unevenly, accelerating micro-cracking and increasing resistance to future bending. Instead, isolate one end, lay the strand flat, and work outward using two fingers to gently “walk” loops open. Patience beats heat every time.

Do LED lights tangle less than incandescent ones?

Marginally—but not for the reasons most assume. LEDs use thinner gauge wire and lighter bulbs, reducing mass-driven snags. However, their higher strand density (more bulbs per foot) and tighter manufacturing tolerances mean smaller gaps for wires to slip through—so once tangled, they’re often harder to separate. The real advantage is longevity: proper wrapping extends LED life to 10+ years versus 3–5 for incandescents.

Is there any benefit to storing lights in the freezer?

No credible evidence supports this. Freezer storage introduces condensation risks upon removal, and thermal cycling stresses solder joints and plastic housings. Cold does not “reset” PVC memory—it only makes it brittle. Stick to stable, dry, moderate temperatures.

Conclusion: Your Lights Deserve Better Than Chaos

Tangling isn’t inevitable—it’s the default outcome of unmanaged physics. But with a few minutes of intentional effort each year, you transform a source of seasonal frustration into a reliable, long-lasting tool. Proper wrapping doesn’t require special talent or expensive gear; it demands only attention to how materials behave and respect for the small mechanical truths that govern them. Every strand you save from the trash is a reduction in e-waste, a quiet win for sustainability, and a tangible return on your holiday investment. More than that, it’s a ritual of care—extending warmth, light, and intention far beyond December.

Start this year—not next. Unwrap your lights mindfully. Inspect deliberately. Wrap with purpose. Store with foresight. And when you plug them in next November, watch them glow—not with nostalgia alone, but with the quiet satisfaction of a system that works, season after season.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?