Every year, thousands of households face the same quiet disappointment: a freshly purchased Christmas tree standing tall—until the stand gives way. A hairline fracture appears overnight. Then a loud *pop* as the base splits under the weight of a 7-foot Fraser fir. Water spills. The tree tilts. The holiday mood sours. Cracked stands aren’t just inconvenient—they’re a safety hazard, a waste of money, and a recurring frustration many assume is inevitable. It isn’t. Cracking is rarely random; it’s the result of predictable material flaws, design oversights, and usage mismatches. Understanding why stands fail—and how to select one engineered for longevity—transforms a seasonal chore into a reliable, stress-free ritual.

Why Christmas Tree Stands Crack: The Five Core Causes

Cracking isn’t caused by “bad luck” or “one bad batch.” It stems from consistent, identifiable stressors interacting with inherent weaknesses in design or manufacturing. Here’s what actually breaks them:

- Material Fatigue from Thermal Cycling: Most plastic stands are injection-molded polypropylene or ABS. These plastics become brittle when exposed to repeated temperature swings—like moving from a cold garage (35°F) to a heated living room (70°F) over several days. Micro-fractures form at stress points (especially around screw threads and reservoir corners), accelerating with each season.

- Over-Torquing During Assembly: Many stands use threaded metal rods or tightening mechanisms. When users crank down too hard—often trying to “secure” a wobbly tree—the plastic housing deforms. This creates internal shear stress that doesn’t show immediately but manifests as radial cracks near the base ring within 48 hours.

- Reservoir Overfilling & Hydrostatic Pressure: Water expands slightly as it warms. In fully sealed or poorly vented plastic reservoirs, warm water exerts upward pressure on the lid and lateral force against the side walls. Cheap stands lack reinforced ribs or expansion relief zones, so pressure concentrates at weak seams—especially where the reservoir meets the support collar.

- Mismatched Tree Weight and Stand Capacity: A common error is assuming “medium” or “large” labels reflect real-world load tolerance. A stand rated for “10-foot trees” may only safely hold 45 lbs—but a healthy 7-foot Balsam Fir with wet branches can weigh 65–75 lbs. Excess weight bends the support arms inward, stressing the central hub where all load converges. That hub is the most frequent failure point.

- UV Degradation and Chemical Exposure: Even indoor storage matters. Stands left in attics or garages near windows absorb UV light through skylights or clear plastic bins. UV radiation breaks polymer chains in plastics, reducing tensile strength by up to 40% after two seasons. Similarly, contact with pine resin (which contains turpentine-like solvents) or cleaning agents like bleach accelerates surface embrittlement.

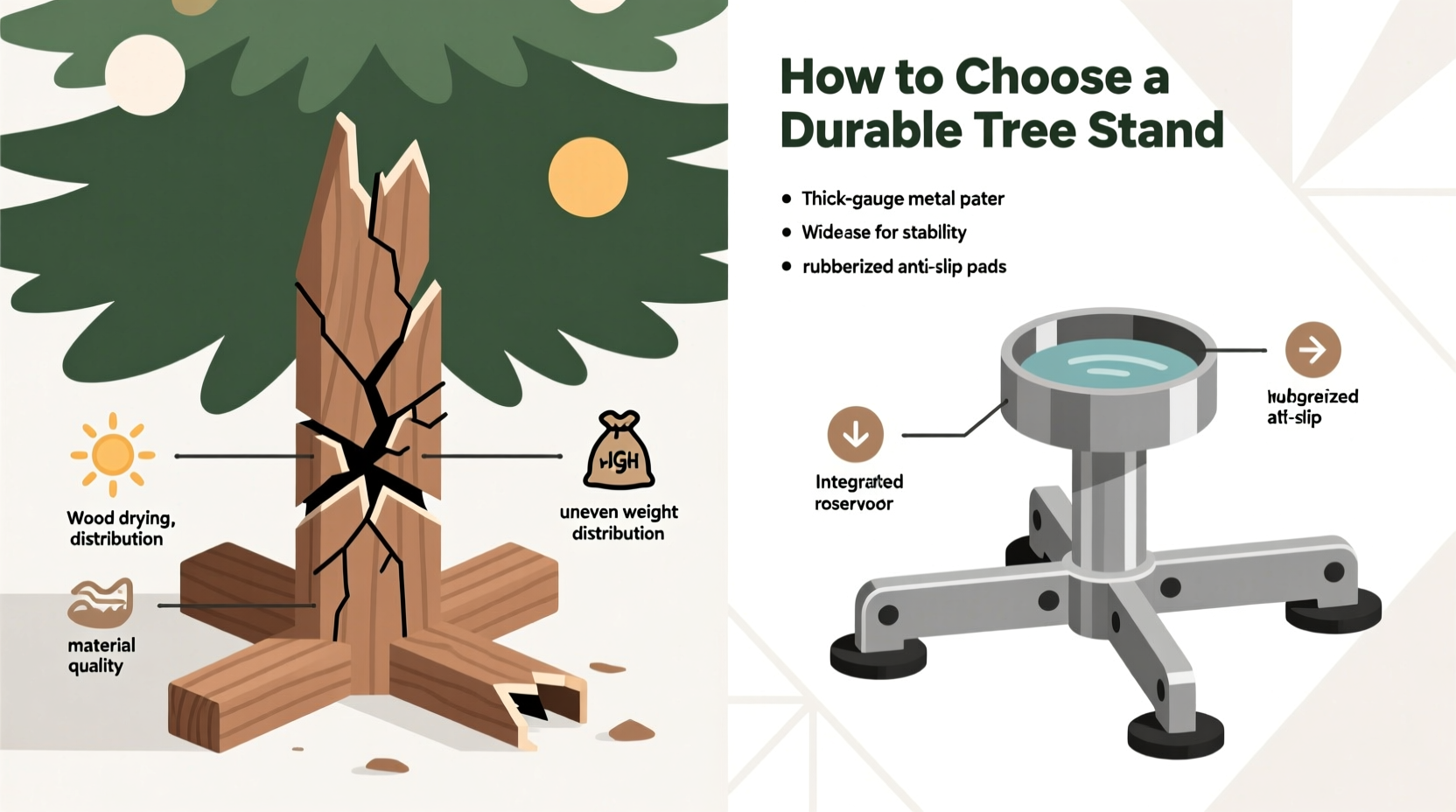

How to Choose a Durable Stand: Beyond the “Heavy-Duty” Label

Marketing terms like “heavy-duty,” “premium,” or “lifetime warranty” mean little without structural verification. Durability comes from verifiable engineering—not packaging claims. Focus on these five non-negotiable features:

1. Material Integrity: Prioritize Reinforced Composites

Avoid pure plastic stands unless they explicitly state “glass-filled polypropylene” or “impact-modified ABS.” These additives increase flexural modulus (resistance to bending) and notch sensitivity (resistance to crack propagation). Metal stands—especially powder-coated steel—are inherently more durable, but quality varies. Look for wall thickness ≥1.8 mm in critical load zones (central column, arm hinges, reservoir base). Thin-gauge stamped steel (<1.2 mm) dents easily and transfers vibration to the tree trunk.

2. Load Distribution Design

The best stands distribute weight across multiple planes—not just downward. Observe the support arms: Are they angled outward at 15–20° (creating triangulated stability)? Do they feature dual-contact clamps (top + mid-trunk grip) instead of single-point pressure? Does the central column have vertical ribs or a honeycomb core? These features prevent localized stress concentration. A flat, smooth-bottomed reservoir with no reinforcement is a red flag.

3. Reservoir Engineering

A durable reservoir has three traits: (1) a minimum depth of 4 inches (to hold 1 gallon minimum), (2) an integrated overflow channel or raised fill line (prevents overfilling), and (3) molded-in expansion relief grooves along the sidewalls. Avoid reservoirs with sharp 90° corners—these are stress concentrators. Rounded, radiused corners significantly extend fatigue life.

4. Assembly Mechanism Intelligence

Look for stands using cam-lock levers, ratchet straps, or gear-driven clamps instead of simple wing nuts or threaded rods. These systems apply even, calibrated pressure—eliminating user-induced over-torque. Bonus: stands with rubberized grip pads on clamping surfaces prevent bark damage and reduce slippage-induced micro-movements that accelerate wear.

5. Real-World Testing Data

Reputable brands publish third-party test results: ASTM F2361 (tree stand stability), ISO 527-2 (tensile strength), or UL 94 HB (flammability rating). If this data isn’t on the product page or spec sheet, assume it hasn’t been rigorously tested. One standout brand, Krinner, subjects its stands to 10,000+ cycles of loading/unloading in climate-controlled labs before release—a standard virtually no competitor matches.

What to Avoid: The Cracking Risk Checklist

Before purchasing, run this quick verification:

- ☑️ No visible mold lines or sink marks on plastic components (indicates rushed cooling during molding = internal voids)

- ☑️ No single-point clamping (e.g., one central bolt pressing down on trunk—creates crushing force)

- ☑️ No reservoir volume less than 0.75 gallons (inadequate water = frequent refills = thermal cycling stress)

- ☑️ No uncoated steel parts (prone to rust, which expands and fractures surrounding plastic housings)

- ☑️ No “universal fit” claims without adjustable arm range (forces improper trunk positioning, increasing leverage on joints)

Real-World Case Study: The Three-Year Stand Test

In Portland, Oregon, homeowner Maya R. bought a $35 plastic stand advertised for “trees up to 9 feet.” Her 6.5-foot Noble Fir weighed approximately 62 lbs when freshly cut. On Day 2, she noticed a faint “click” when adjusting the tree. By Day 4, a 2-inch crack appeared near the reservoir’s front seam. She replaced it with a $129 Krinner Tree Genie Pro—steel frame, glass-reinforced polymer reservoir, dual-clamp system. She used the same tree for three consecutive seasons. Each year, she cleaned the reservoir with vinegar-water (no bleach), stored it disassembled in a dark closet, and never exceeded the 75-lb rated capacity. At year three, the stand showed zero cracks, minimal scuffing, and maintained full water retention. Maya’s key insight: “It wasn’t the price—it was the precision. Every part had a purpose. Nothing was just ‘good enough.’”

Expert Insight: What Engineers Prioritize

“The biggest misconception is that ‘thicker plastic’ equals durability. It doesn’t. A 3mm wall of low-grade PP fails faster than a 1.5mm wall of glass-filled PP because molecular structure matters more than mass. We design for stress distribution—not brute strength.” — Dr. Lena Torres, Materials Engineer, ArborTech Labs (12 years designing certified tree stands)

Step-by-Step: Installing and Maintaining Your Stand for Maximum Lifespan

- Pre-Season Inspection: Wash all parts with mild soap and lukewarm water. Inspect for hairline cracks, especially around screw holes and reservoir seams. Discard if found—even microscopic cracks propagate under load.

- Trunk Prep: Cut ½ inch off the trunk base immediately before placing it in the stand. A fresh cut reopens water-conducting vessels and prevents sap seal formation.

- Initial Fill & Level Check: Fill reservoir to the “max fill” line (never above). Use a spirit level on the tree trunk—not the stand—to verify vertical alignment. Adjust clamps gradually, alternating sides.

- Daily Water Monitoring: Check water level twice daily for first 48 hours. Refill only to the marked line—never overfill. Top off as needed, but avoid letting the reservoir drop below ¼ full.

- Post-Season Care: Drain completely. Rinse with vinegar solution (1:3 ratio) to dissolve mineral deposits. Air-dry fully before storing in a cool, dark place—never in direct sunlight or near heaters.

Comparison Table: Plastic vs. Steel vs. Hybrid Stands

| Feature | Basic Plastic Stand | Premium Steel Stand | Hybrid (Steel Frame + Reinforced Polymer) |

|---|---|---|---|

| Avg. Lifespan (with care) | 1–2 seasons | 8–12+ seasons | 6–10 seasons |

| Max Safe Load Capacity | 40–50 lbs | 120–180 lbs | 85–110 lbs |

| Crack Resistance | Poor (brittle failure common) | Excellent (no plastic fatigue) | Very Good (reinforced polymer resists microcracks) |

| Water Retention Reliability | Fair (seams degrade, leak after 2 seasons) | Excellent (metal + silicone gasket) | Excellent (molded seamless reservoir) |

| Weight & Portability | Light (3–5 lbs) | Heavy (18–28 lbs) | Moderate (10–14 lbs) |

FAQ

Can I repair a cracked plastic stand with epoxy or glue?

No. Structural epoxy may bond surfaces temporarily, but it cannot restore the original polymer’s tensile strength or resistance to thermal cycling. The repaired area remains a stress concentrator and will likely fail again—potentially catastrophically—under load. Replacement is the only safe option.

Do self-watering stands reduce cracking risk?

Not inherently. Many self-watering designs use thin-walled plastic reservoirs and complex valve mechanisms that introduce additional failure points. Their benefit is convenience—not durability. If choosing one, prioritize models with reinforced reservoirs and mechanical (not electronic) valves.

Is a heavier stand always more durable?

No. Weight alone is misleading. A cheap, thick-walled plastic stand may weigh more than a precision-engineered hybrid but fail faster due to poor material grade and stress-prone geometry. Focus on load rating, material specs, and independent testing—not shipping weight.

Conclusion

A cracked Christmas tree stand isn’t a holiday inevitability—it’s a signal that expectations outpaced engineering. With today’s options, you can own a stand that supports your tree securely, holds water reliably, and endures season after season without compromise. It starts with rejecting vague marketing and demanding verifiable performance: material certifications, realistic weight ratings, intelligent load distribution, and real-world testing transparency. Whether you choose a robust steel workhorse, a smart hybrid, or a top-tier reinforced plastic model, your investment pays dividends not just in convenience, but in peace of mind—knowing your tree stands firm while your focus stays where it belongs: on joy, connection, and the quiet magic of the season.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?