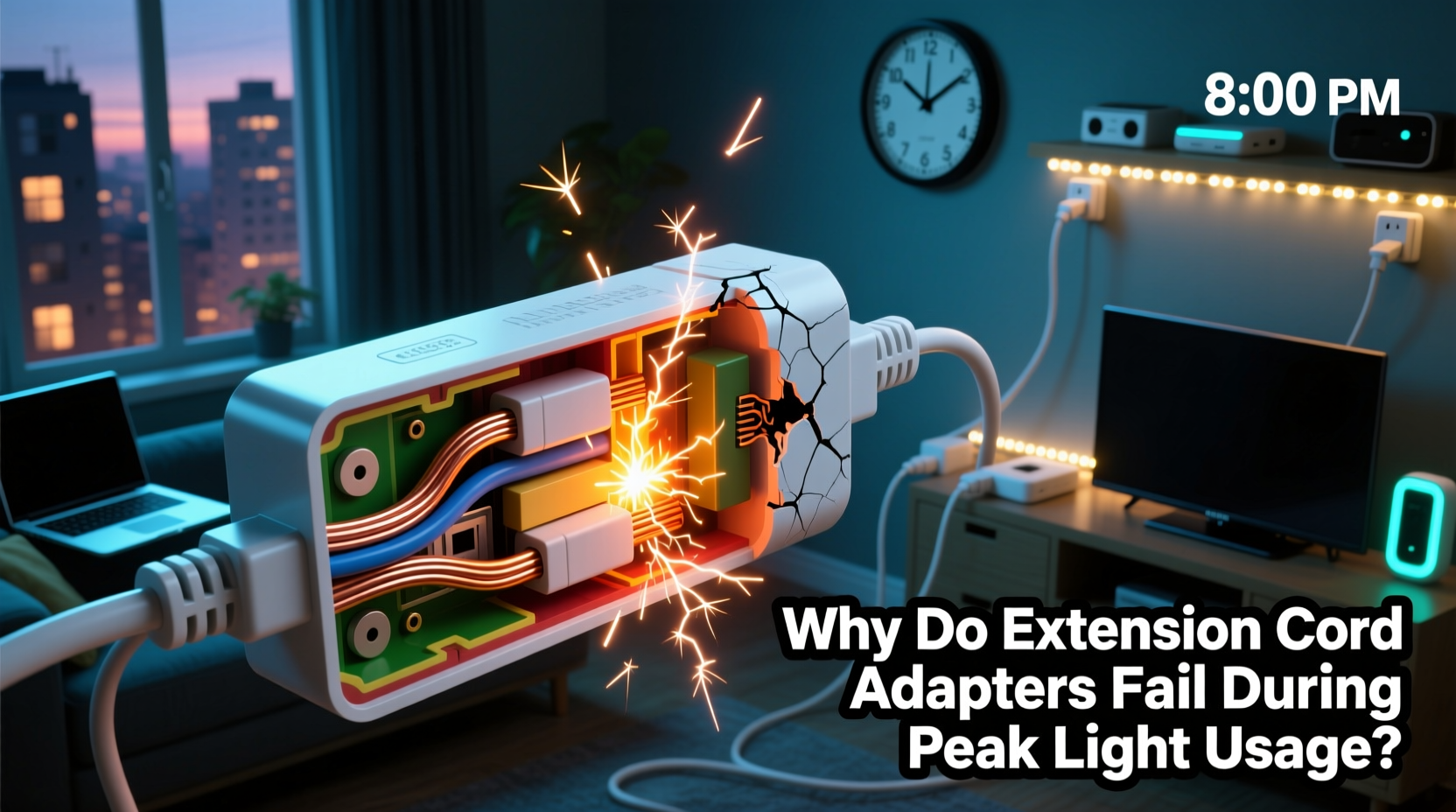

During holiday seasons, festivals, or large indoor gatherings, the demand for lighting surges. String lights, decorative LEDs, spotlights, and illuminated displays create vibrant atmospheres—but behind the sparkle lies a common and often overlooked hazard: failing extension cord adapters. These small connectors are frequently pushed beyond their limits when multiple light strands draw power simultaneously. Understanding why these failures occur is essential not only for maintaining functionality but also for preventing fire risks, equipment damage, and electrical hazards.

The root causes of adapter failure during peak light use stem from a combination of design limitations, improper load management, environmental stress, and user error. While many assume that plugging in more lights simply means using longer cords, the reality involves complex interactions between current draw, wire gauge, connector quality, and thermal regulation. When ignored, these factors lead to overheating, melting insulation, short circuits, and even complete system shutdowns.

Understanding Electrical Load and Adapter Ratings

Every extension cord and adapter has a maximum electrical capacity measured in amperes (amps) or watts. Standard household circuits in the U.S. operate at 120 volts and are typically protected by 15- or 20-amp breakers. This means a single circuit can safely handle up to 1,800 watts (15A × 120V) or 2,400 watts (20A × 120V). However, this total must be shared across all devices on the circuit—including lights connected through adapters.

Lighting loads vary significantly. Incandescent mini-lights may consume 40–100 watts per 100-bulb strand, while modern LED strings use as little as 5–10 watts for the same length. The problem arises when users daisy-chain multiple strands without considering cumulative draw. A single low-quality adapter rated for only 5 amps (600 watts) might be overloaded by six incandescent light sets drawing 720 watts combined—exceeding its safe limit by 20%.

Manufacturers often label adapters with vague terms like “suitable for indoor use” or “multi-outlet,” but rarely emphasize real-world constraints. Consumers mistakenly believe that if an adapter fits into an outlet and powers one string, it can handle several. In truth, internal contacts, plastic housing, and wire gauges inside cheap adapters are not engineered for sustained high loads.

Heat Buildup and Material Degradation

One of the primary reasons extension cord adapters fail under heavy lighting use is excessive heat generation. As electric current flows through metal conductors, resistance causes energy loss in the form of heat. Under normal conditions, this heat dissipates harmlessly. But when too much current passes through undersized wires or poor-quality connectors, temperatures rise rapidly.

Inexpensive adapters often use thin copper alloys or even aluminum for internal contacts. These materials have higher resistance than pure copper and generate more heat under load. Combined with flammable thermoplastic housings, this creates a dangerous feedback loop: increased temperature softens insulation, increases contact resistance further, and eventually melts solder joints or warps socket alignment.

A telltale sign of thermal stress is discoloration—yellowing or browning around plug prongs or outlet ports. Once visible, this indicates irreversible damage. Even if the adapter still functions, its structural integrity is compromised, increasing the risk of arcing or fire.

“Many consumers don’t realize that heat buildup in a seemingly minor adapter can reach ignition points within minutes under overload. It's not about whether it works—it's about whether it’s safe.” — Dr. Alan Reyes, Electrical Safety Engineer, NFPA

Common Causes of Adapter Failure During Peak Lighting

Several interrelated factors contribute to adapter breakdowns when lighting demands spike. Identifying these helps prevent avoidable failures:

- Daisy-chaining multiple adapters: Connecting one multi-plug adapter to another multiplies connection points and resistance, creating hotspots.

- Using indoor-rated adapters outdoors: Moisture ingress corrodes contacts and reduces conductivity, forcing remaining pathways to carry excess current.

- Poor ventilation: Adapters buried under rugs, furniture, or decorations cannot dissipate heat effectively.

- Loose connections: Worn outlets or mismatched plug sizes cause intermittent contact, leading to sparking and pitting.

- Overloading individual ports: Plugging high-draw devices like heaters or projectors into the same adapter as lights accelerates failure.

Moreover, seasonal lighting setups often involve temporary installations where safety checks are skipped. Users prioritize aesthetics over electrical planning, resulting in overloaded circuits hidden behind walls or under carpets. By the time a problem becomes evident—such as flickering lights or a burning smell—the damage may already be underway.

How to Prevent Adapter Failures: A Step-by-Step Guide

Preventing failure isn’t complicated, but it requires attention to detail and disciplined setup practices. Follow this timeline-based guide before deploying any large-scale lighting display:

- Day 1: Inventory and assess your equipment

Create a list of all lights, including voltage, wattage, and quantity. Calculate total expected load per circuit. - Day 2: Verify adapter specifications

Check each adapter’s amp/watt rating. Replace any unlabeled or damaged units with UL-listed models rated for at least 15 amps. - Day 3: Plan circuit distribution

Divide lighting loads evenly across multiple wall outlets on different circuits. Avoid concentrating everything on one breaker. - Day 4: Test setup incrementally

Power on one section at a time. Monitor for warmth, buzzing sounds, or dimming—early signs of strain. - Day 5: Final inspection and deployment

Ensure all adapters are placed in open, dry areas with airflow. Secure cords to prevent tripping or tension on plugs.

This methodical approach minimizes risk and ensures long-term reliability. For permanent installations—like stage lighting or retail displays—consider hardwiring dedicated circuits instead of relying on portable adapters.

Do’s and Don’ts: Extension Cord Adapter Use During High-Demand Lighting

| Action | Do | Don't |

|---|---|---|

| Load Management | Keep total load below 80% of adapter rating | Daisy-chain multiple high-wattage light strings |

| Location | Place adapters in open, ventilated areas | Hide them under carpets or behind curtains |

| Weather Conditions | Use outdoor-rated, weatherproof adapters outside | Expose indoor-only adapters to rain or snow |

| Maintenance | Inspect for fraying, melting, or discoloration monthly | Continue using adapters showing physical damage |

| Connection Quality | Ensure snug fit; replace loose or wobbly units | Force bent prongs into outlets |

Real-World Example: Festival Lighting Meltdown

At a community winter festival last December, organizers decorated a central plaza with over 500 feet of multicolored string lights powered through three main extension cord hubs. Each hub used a standard five-outlet indoor power strip connected to a single outdoor outlet via a 50-foot extension cord. Within two hours of activation, one hub began emitting smoke. Attendees reported a sharp plastic odor before the entire section went dark.

An investigation revealed that the failed unit had been supplying 2,100 watts—nearly double its 1,200-watt capacity. The internal wiring had melted, causing adjacent sockets to fuse together. Fortunately, no fire occurred due to timely detection, but repairs delayed the event by two days.

The lesson? Even professional teams can overlook basic electrical principles when focused on visual impact. After replacing all non-compliant adapters with industrial-grade, fused surge protectors and redistributing loads across additional circuits, the display ran safely for the remainder of the season.

Frequently Asked Questions

Can I use a regular power strip for outdoor holiday lights?

No—not unless it is explicitly labeled for outdoor use. Indoor strips lack weather-resistant enclosures and corrosion protection. Using them outside exposes live components to moisture, drastically increasing shock and fire risks. Always choose outdoor-rated adapters with GFCI protection for exterior lighting.

Why did my adapter fail even though I didn’t exceed the wattage?

Wattage is only part of the equation. Poor build quality, age-related wear, ambient temperature, and voltage fluctuations can all contribute to premature failure. Even within rated limits, low-cost adapters may overheat due to inefficient internal design or degraded materials. Regular replacement every few years is recommended for frequently used units.

Are smart plug adapters safer for lighting control?

Smart adapters can offer safety advantages—if they include overload sensing and automatic shutoff features. Many models monitor real-time current and disconnect power when thresholds are exceeded. However, they are not inherently safer just because they’re \"smart.\" Always verify their electrical ratings and ensure compatibility with your lighting type, especially when controlling inductive or capacitive loads like transformers or dimmers.

Expert Recommendations for Long-Term Reliability

Professionals in event production and facility management follow strict protocols to avoid adapter failures. Their best practices reflect decades of field experience:

- Use only UL-listed or ETL-certified adapters—never unbranded or counterfeit products.

- Label circuits and map loads during installation to prevent accidental overloads.

- Install thermal fuses or resettable breakers in custom lighting rigs.

- Train staff to recognize early warning signs: warm housings, buzzing noises, or inconsistent brightness.

“The most reliable system isn’t the cheapest one that works today—it’s the one that won’t fail tomorrow. Invest in quality connectors the way you would in insurance.” — Maria Tran, Lead Technician, City Events & Lighting Co.

Conclusion: Prioritize Safety Over Convenience

Extension cord adapters failing during peak light usage is not inevitable—it’s preventable. Behind every malfunction lies a chain of oversights: misjudged loads, poor-quality hardware, or inadequate planning. With rising adoption of energy-efficient LEDs, overall power consumption has decreased, but the temptation to connect more lights persists. More connections mean more potential failure points.

By respecting electrical limits, choosing durable components, and designing systems with redundancy and airflow, you protect not only your investment but also the people around you. Whether illuminating a backyard party or managing a commercial display, treat every adapter as a critical node in your electrical network—not just a convenience.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?