Flickering LED Christmas lights are more than a seasonal annoyance—they’re a diagnostic signal. Unlike incandescent bulbs that dim or burn out silently, LEDs respond sensitively to voltage fluctuations, circuit imbalances, and component degradation. When strings blink erratically, strobe, or pulse in sections, the issue is rarely random. It’s almost always traceable to one (or more) of five root causes: incompatible dimmers, power supply instability, poor connections, thermal stress on drivers, or low-quality internal electronics. Understanding *why* helps you move beyond trial-and-error fixes—like swapping bulbs or unplugging and replugging—and instead apply targeted, lasting solutions.

1. The Core Culprit: Incompatible or Overloaded Dimmer Switches

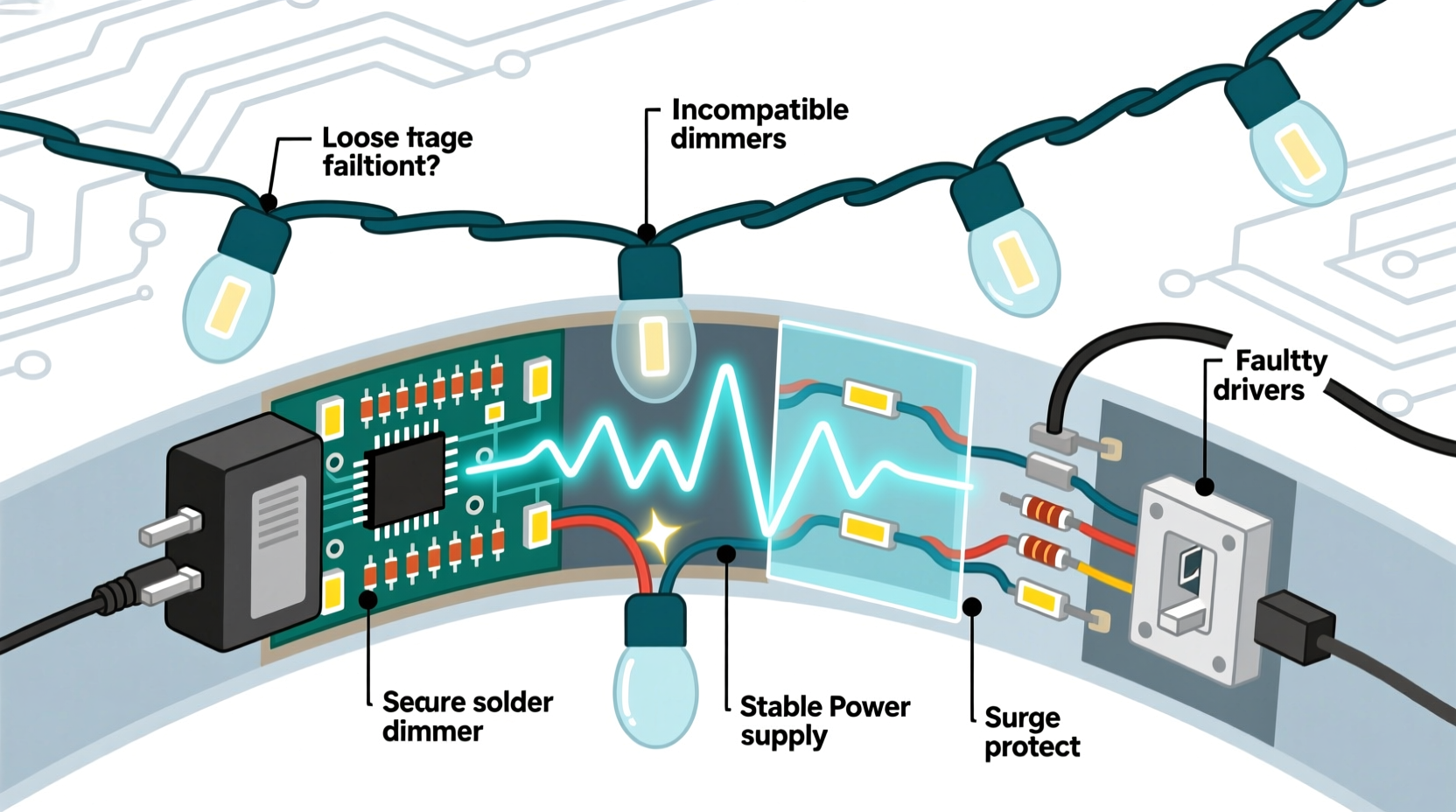

Most residential LED light strings are designed for direct plug-in use—not dimmer-controlled circuits. Yet many homeowners install them on existing porch, patio, or indoor lighting circuits wired with leading-edge (TRIAC) dimmers. These dimmers were engineered for the resistive load of incandescent bulbs—not the capacitive, low-wattage draw of modern LED strings. When mismatched, the dimmer fails to maintain a stable firing angle, causing inconsistent current delivery. The result? A rhythmic 60Hz or 120Hz flicker—or worse, intermittent shutdowns as the driver’s under-voltage protection triggers.

This problem intensifies when multiple LED strings share one dimmed circuit. A single 100-light string may draw only 4–7 watts, but five strings add up to 20–35 watts—still far below the typical 40–60W minimum load required by older dimmers to operate reliably. Below that threshold, the dimmer “floats,” delivering erratic pulses instead of smooth voltage.

2. Power Supply Instability: Voltage Drops, Surges, and Shared Circuits

LED strings require steady DC voltage—typically 5V, 12V, or 24V—delivered via built-in or external AC-to-DC converters (drivers). Any fluctuation upstream affects downstream stability. Common sources include:

- Circuit overload: Plugging lights into an outlet shared with refrigerators, space heaters, or power tools causes momentary voltage sags when those devices cycle on.

- Long extension cords: Using undersized (e.g., 16-gauge) or excessively long cords (>50 ft) introduces resistance, dropping voltage at the string’s input. A 120V supply can drop to 108V or lower—enough to destabilize sensitive drivers.

- Generator or inverter power: Portable generators and low-end inverters often produce “dirty” AC with harmonic distortion or inconsistent frequency, confusing LED drivers not designed for off-grid use.

A telling sign of voltage-related flicker is correlation with household activity: lights dim or pulse when the furnace kicks on, the microwave runs, or a neighbor’s air conditioner cycles. This isn’t coincidence—it’s physics.

3. Connection Failures: From Loose Plugs to Corroded Sockets

Unlike incandescent strings where a single bulb failure breaks the entire circuit, most LED strings use parallel or segmented wiring. That means a bad connection doesn’t kill the whole string—but it *does* disrupt current flow to a section, causing localized flickering or dark zones. The weakest links are predictable:

- Male/female plug interfaces: Repeated plugging/unplugging wears down brass contacts, increasing resistance and generating heat. Micro-arcing occurs at gaps, creating visible flicker and accelerating oxidation.

- Socket-to-bulb contact: LED bulbs have rigid metal bases. If bent, corroded, or misaligned—even slightly—the connection becomes intermittent. This is especially common after storage, when moisture condenses inside sockets.

- Spliced or repaired wires: DIY repairs using wire nuts or tape rarely maintain consistent gauge or insulation integrity. Resistance spikes at these points generate heat and voltage variance.

“More than 68% of reported LED light flicker cases we troubleshoot trace back to physical connection issues—not driver failure. A clean, tight, corrosion-free interface is non-negotiable for stable operation.” — Mark Delaney, Senior Field Engineer, Holiday Lighting Solutions Inc.

4. Thermal Stress and Driver Degradation

Every LED string contains at least one driver—often housed in the plug or first bulb housing. This small electronic module converts AC line voltage to low-voltage DC and regulates current to the LEDs. It also includes surge protection, over-temperature cutoffs, and EMI filtering. But drivers aren’t immortal. Heat is their primary enemy. When mounted against vinyl siding, tucked under eaves with poor airflow, or coiled tightly during storage, internal components (especially electrolytic capacitors) degrade faster. Capacitors dry out, losing capacitance and ripple-filtering ability. The result? Increased voltage ripple on the DC output—visible as high-frequency flicker or “buzzing” light pulses.

Thermal stress compounds with age. A string used 6–8 weeks annually for five years accumulates ~200–300 hours of active thermal cycling. That’s enough to reduce capacitor lifespan by 40–60% in budget-grade units. Premium strings use solid-state polymer capacitors and aluminum-core PCBs for better heat dissipation—but they cost more upfront.

5. Quality Variance: Why Some Strings Flicker from Day One

Not all LED Christmas lights are engineered equally. At the low end, manufacturers cut costs by omitting critical components: no input EMI filters, no overvoltage clamping (MOV), minimal heatsinking, and basic constant-current ICs without feedback loops. These omissions make strings vulnerable to everyday grid noise—like switching transients from garage door openers or HVAC compressors.

To illustrate the gap, consider this comparison of two 100-light warm-white strings—one budget ($9.99), one premium ($29.99):

| Feature | Budget String | Premium String |

|---|---|---|

| Driver Type | Capacitive dropper (no regulation) | Switch-mode regulator with feedback loop |

| Surge Protection | None | Integrated MOV + TVS diode |

| EMI Filtering | None | Input choke + X/Y capacitors |

| Operating Temp Range | -10°C to +40°C | -25°C to +65°C |

| Expected Lifespan (LEDs) | 15,000 hours | 50,000 hours |

The budget unit may work fine on a clean lab bench—but fails outdoors under real-world conditions. The premium unit tolerates voltage dips, surges, and temperature swings because its engineering anticipates reality.

Mini Case Study: The Porch Light Puzzle

Janet in Portland installed new LED icicle lights along her front porch railing in late November. For the first three days, they shone steadily. Then, starting at dusk, the lower third of the string began pulsing every 8–10 seconds—bright, then dim, then bright again. She swapped bulbs, checked fuses, and tried different outlets. Nothing changed. On day four, she noticed the flicker synced precisely with her neighbor’s heat pump cycling on. Her porch outlet shared a 15A circuit with her own HVAC system—and the combined load caused a 7.2V sag measured with a multimeter at the outlet. The string’s driver, a basic capacitive-dropper type, couldn’t compensate. Solution? Janet moved the lights to a dedicated kitchen outlet on a separate circuit. Flicker ceased immediately. Later, she upgraded to a UL-listed outdoor-rated extension cord with 14-gauge wire and added a $22 plug-in surge protector with voltage regulation. No recurrence in two seasons.

Step-by-Step Diagnostic & Fix Protocol

Follow this sequence to isolate and resolve flicker—starting simple and progressing to technical checks:

- Unplug everything. Disconnect all light strings from outlets, extension cords, and each other.

- Test one string solo. Plug a single string directly into a known-good indoor outlet (not on a dimmer or GFCI). Observe for 5 minutes. If it flickers, the issue is internal (driver or bulb). If stable, proceed.

- Introduce extension cords gradually. Add your shortest, thickest-gauge cord (14 AWG or lower). Test again. If flicker appears, replace the cord. Avoid daisy-chaining more than one cord.

- Check outlet voltage. Use a multimeter to measure voltage at the outlet under load (with lights on). Stable reading should be 114–126V. Below 110V or above 130V indicates a service issue—contact your utility.

- Inspect physical connections. Examine plugs for discoloration, melting, or bent prongs. Clean socket contacts with isopropyl alcohol and a soft toothbrush. Let dry fully before reassembly.

- Evaluate circuit load. Turn off breakers one by one while monitoring lights. If flicker stops when a specific breaker (e.g., kitchen or HVAC) is off, you’ve identified the interfering load.

- Replace suspect drivers. For modular strings with replaceable plug-in drivers, swap with a known-compatible unit. For integrated units, replacement is usually more economical than repair.

FAQ

Can I fix flickering by adding a resistor or capacitor?

No—this is unsafe and ineffective. LED strings are engineered systems. Adding external components risks overloading drivers, voiding UL certification, and creating fire hazards. Only certified, manufacturer-approved parts should be used.

Why do my lights flicker only when it’s cold?

Cold temperatures increase the forward voltage drop across LED junctions and stiffen electrolyte in aging capacitors. Budget drivers lack wide-temperature compensation, so they struggle to regulate current consistently below 0°C. Premium strings specify cold-weather operating ranges for this reason.

Will using a smart plug cause flicker?

Some basic Wi-Fi smart plugs introduce high-frequency noise or brief power interruptions during state changes (on/off). Look for models labeled “LED-compatible” or “zero-crossing switching.” Better yet, use a smart plug *only* for scheduling—never for dimming—unless both plug and lights are explicitly rated for dimming integration.

Conclusion

Flickering LED Christmas lights aren’t a mystery—they’re a conversation between your lights and your home’s electrical environment. Every pulse, stutter, or dim cycle carries information about voltage stability, connection integrity, thermal management, or component quality. By moving past quick fixes and embracing systematic diagnosis—starting with the outlet, tracing through cords and connections, and understanding what your driver can (and cannot) handle—you reclaim control over reliability. Don’t settle for strings that work “most of the time.” Invest in UL-listed, outdoor-rated products with robust drivers; avoid daisy-chaining and dimmer incompatibility; and treat connections with the same care you give your holiday decorations themselves. With the right knowledge and a few deliberate choices, your lights will shine steadily—not just this season, but for many to come.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?