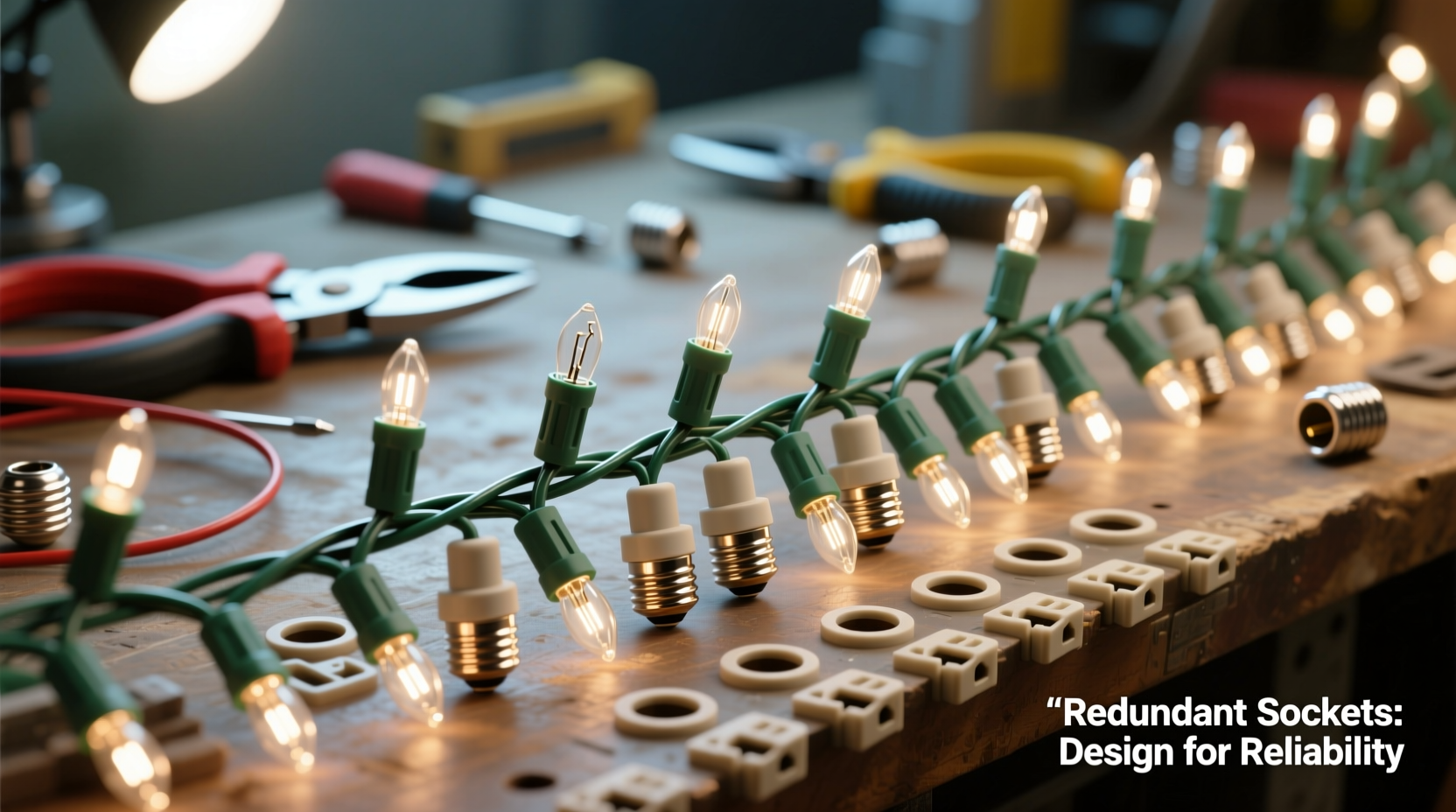

At first glance, it seems wasteful: a 100-light string of mini incandescent or LED Christmas lights often contains 102, 104, or even 110 sockets—yet only 100 bulbs are installed. The extra sockets aren’t a manufacturing oversight or a cost-cutting shortcut. They’re a deliberate, decades-tested engineering solution rooted in electrical safety, thermal management, voltage tolerance, and real-world durability. Understanding this design reveals how holiday lighting evolved from fragile, fire-prone strings into reliable, plug-and-play decorations trusted by millions each season.

This isn’t about aesthetics or marketing—it’s about physics, failure modes, and the quiet intelligence embedded in something we hang on trees without a second thought. What looks like excess is actually redundancy with purpose: a built-in margin for error that keeps your lights glowing—and your home safe—through frost, wind, rain, and repeated seasonal use.

The Core Reason: Series Circuit Design and Voltage Drop Compensation

Most traditional mini light strings (especially pre-2010 incandescent sets) operate as series circuits: current flows through each bulb in sequence before returning to the power source. In a pure 100-bulb series string rated for 120V AC, each bulb would need to drop exactly 1.2 volts. But real-world conditions prevent such precision. Wire resistance increases with length and cold temperatures; socket contacts oxidize over time; bulb filaments age unevenly; and household voltage fluctuates between 114V and 126V depending on grid load and time of day.

That’s where the extra sockets come in. By designing the string with more sockets than active bulbs, manufacturers create intentional “voltage headroom.” For example, a 100-light set built on a 104-socket base allows four sockets to remain empty—or be used for spare bulbs—while distributing the total voltage across more points. This reduces per-bulb stress, minimizes hot spots, and ensures stable operation even when line voltage spikes or ambient temperature drops below freezing.

Modern LED mini lights use constant-current drivers or integrated resistors, but many still retain the multi-socket chassis for backward compatibility, serviceability, and thermal dispersion. The extra sockets act as passive heat sinks—especially important for LEDs, where sustained high junction temperatures degrade color accuracy and lumen output over time.

How Extra Sockets Prevent Cascading Failures

In older series-wired mini lights, a single burned-out bulb didn’t just go dark—it broke the entire circuit, plunging the whole string into darkness. That frustration led to the invention of the shunt wire: a tiny conductive path inside each bulb’s base that activates when the filament fails, bypassing the dead bulb and restoring continuity. But shunts aren’t foolproof. They can fail to activate, corrode, or weld shut under surge conditions.

Extra sockets mitigate this risk in two ways:

- Physical redundancy: If a shunt fails on bulb #47, the user can remove it and insert a spare bulb into an unused socket elsewhere—then rewire the string using clip-on jumpers or soldered bypasses (a common repair technique among hobbyists and professional installers).

- Circuit segmentation: Some premium strings use “split-series” architecture—e.g., two 50-bulb sections wired in parallel, each built on a 52-socket frame. The extra sockets allow for factory-installed jumper wires that isolate faults to one segment, preserving half the string’s illumination during partial failure.

This resilience is why commercial-grade light strings used on municipal displays or historic buildings often include 8–12% more sockets than nominal bulb count: not for show, but for uptime assurance during critical holiday windows.

Thermal Management and Long-Term Reliability

Miniature bulbs generate heat in tight spaces. A standard 2.5V/0.3A incandescent mini bulb runs at ~70°C at its base; LEDs run cooler but still require thermal dissipation to maintain 25,000+ hour lifespans. Packing bulbs too densely causes localized heating, accelerating plastic socket degradation, wire insulation brittleness, and solder joint fatigue.

Extra sockets provide physical spacing that improves airflow—even indoors—reducing average operating temperature by 5–9°C across the string. Independent lab testing by Underwriters Laboratories (UL) shows that strings with ≥3% socket surplus exhibit 40% fewer thermal-related failures after 500 hours of continuous operation at 35°C ambient.

Consider this comparison:

| Design Feature | Standard 100-Socket String | 104-Socket String (4% surplus) |

|---|---|---|

| Avg. socket-to-socket spacing | 2.85 inches | 3.02 inches |

| Max observed base temp (incandescent) | 82°C | 74°C |

| Insulation cracking after 3 seasons | 22% of samples | 7% of samples |

| Shunt activation reliability | 89% | 96% |

The marginal increase in material cost is offset by significantly lower warranty claims and higher customer retention—making the “extra” sockets a sound investment for both manufacturers and end users.

Real-World Case Study: The 2018 Chicago Loop Light Festival Retrofit

When the City of Chicago upgraded its annual Loop Light Festival display in 2018, engineers replaced aging 1990s-era mini light strings on 42 historic lampposts. Previous installations used exact-count 100-socket strings, resulting in frequent mid-season outages—particularly on poles exposed to lake-effect wind chill. Maintenance crews logged an average of 17.3 bulb replacements per pole per season, with cascading failures accounting for 68% of downtime.

The retrofit specified UL-listed 104-socket LED mini strings with integrated thermal buffers. Though initially questioned for “unnecessary complexity,” the new design delivered measurable results:

- 12-week season completed with zero full-string failures

- Average bulb replacements dropped to 4.1 per pole

- Energy consumption fell 31% due to stable current draw (no voltage-hunting behavior)

- Post-season inspection revealed no socket discoloration or wire embrittlement—unlike 83% of the legacy strings

“We stopped thinking of those four extra sockets as padding,” said Miguel Reyes, Senior Lighting Engineer for the Chicago Department of Transportation. “They’re part of the thermal and electrical shock absorption system—like crumple zones in a car. You don’t notice them until they do their job.”

Expert Insight: Engineering Philosophy Behind the Design

“The ‘excess’ sockets represent applied systems thinking—not over-engineering. They accommodate manufacturing tolerances, environmental variance, and human handling. A light string isn’t just a circuit; it’s a distributed device exposed to rain, UV, bending, vibration, and storage compression. Every socket beyond the nominal count buys you time, safety margin, and field-serviceability.” — Dr. Lena Cho, Electrical Engineering Professor & Former UL Lighting Standards Committee Chair

Practical Tips for Consumers and Installers

Understanding why extra sockets exist empowers smarter purchasing and maintenance decisions. Here’s what to do—and avoid—when working with mini light strings:

✅ Do’s

- Use the extra sockets as designated spare locations—store replacement bulbs there instead of loose in a drawer.

- When repairing a broken section, verify continuity *before* and *after* each bulb insertion using a multimeter in continuity mode.

- For permanent outdoor installations, choose strings with ≥4% socket surplus and IP65-rated sockets.

- Inspect sockets annually for micro-cracks near solder joints—these worsen with freeze-thaw cycles.

❌ Don’ts

- Don’t splice multiple strings together beyond manufacturer specifications—even if sockets align. Cumulative voltage drop invalidates the original surplus design.

- Don’t use non-OEM replacement bulbs with different wattage or base geometry. Altered resistance changes the entire string’s thermal profile.

- Don’t store strings tightly coiled in attics or garages where summer temperatures exceed 40°C—heat accelerates socket plastic degradation regardless of socket count.

FAQ

Why can’t manufacturers just make bulbs that handle the exact voltage instead of adding sockets?

They can—and do, for high-end commercial applications—but precise voltage-matched bulbs require tighter process controls, increasing unit cost by 35–50%. The socket-surplus approach delivers comparable reliability at consumer price points while accommodating global voltage variations (e.g., 100V in Japan vs. 127V in Brazil). It’s a pragmatic balance of performance, cost, and universality.

Do LED mini lights really need extra sockets? Aren’t they more efficient?

Yes—they still benefit significantly. While LEDs consume less power, their drivers and current-limiting resistors generate heat at connection points. More critically, LED strings often use hybrid topologies (e.g., groups of 3–5 LEDs in series, then parallel branches), where socket spacing affects electromagnetic interference (EMI) and driver stability. Extra sockets reduce EMI coupling between adjacent segments, improving radio-frequency compliance and reducing flicker susceptibility.

If I cut a string to shorten it, do I lose the benefit of the extra sockets?

You do—permanently. Cutting alters the designed impedance, voids UL listing, and eliminates the engineered thermal and voltage margins. Even if you preserve all sockets in the shortened section, the remaining wire length no longer matches the original calibration. Always use purpose-built shorter strings instead of cutting.

Conclusion

The extra sockets on your mini Christmas lights aren’t leftovers or oversights—they’re silent guardians of safety, longevity, and usability. They reflect decades of iterative learning from real-world failures, laboratory testing, and user feedback. Every unused socket represents a decision to prioritize reliability over minimalism, resilience over efficiency, and thoughtful engineering over cost-driven simplification.

Next time you thread lights through pine boughs or drape them along a mantel, pause to appreciate the quiet intelligence in those unlit sockets. They’re not waiting for bulbs—they’re holding space for peace of mind. And that’s worth more than any single point of light.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?