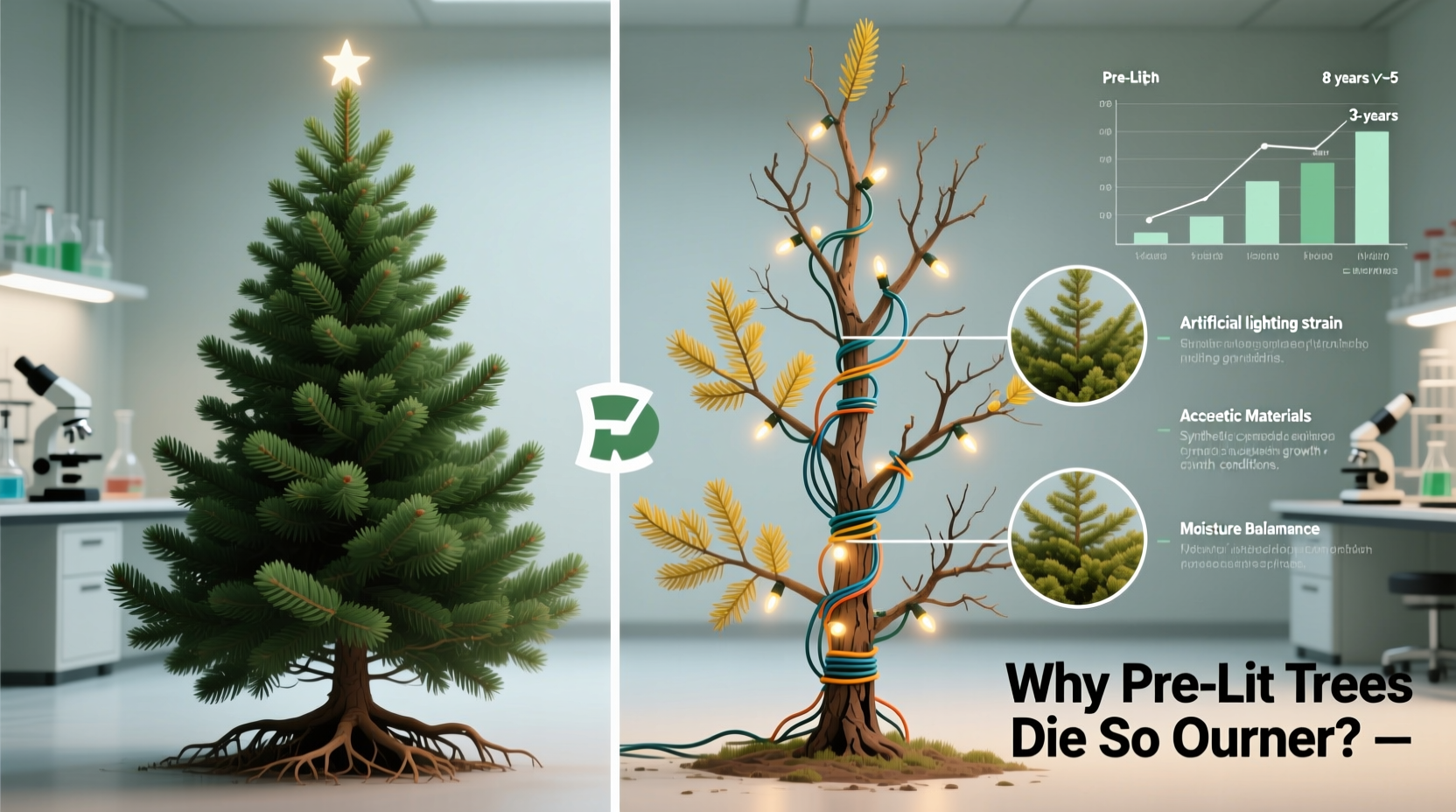

Prelit Christmas trees promise convenience, time savings, and instant holiday cheer — plug in the tree, fluff the branches, and you're done. Yet many consumers find themselves replacing these trees far sooner than anticipated, sometimes after just a few seasons. While marketed as durable, long-term investments, prelit trees frequently fail to meet expectations. The reasons are not always obvious, but they stem from a combination of design compromises, manufacturing limitations, and user habits that accelerate wear. Understanding these factors can help buyers make smarter decisions and potentially extend the usable life of their trees.

Design Trade-offs: Convenience vs. Durability

The core appeal of a prelit tree is its integrated lighting system. Manufacturers embed hundreds or even thousands of LED bulbs directly into the branches during assembly, eliminating the need for stringing lights manually. However, this integration comes at a cost. Unlike traditional artificial trees where lights can be replaced independently, the wiring in prelit models is permanent. If one section fails, it can compromise the entire circuit, rendering large portions of the tree dark.

This design makes repair nearly impossible for the average consumer. Most prelit trees use series-wired circuits, meaning that if a single bulb burns out or becomes loose, the current stops flowing through the rest of the strand. While some newer models feature shunt technology (which allows current to bypass dead bulbs), many budget-friendly options still rely on older systems prone to cascading failures.

Additionally, the process of attaching lights during manufacturing introduces stress points. Wires must be threaded through plastic branch tips, often secured with glue or clips that degrade over time. Repeated folding and unfolding during storage weakens these connections, increasing the likelihood of internal breaks that are difficult to detect or fix.

Material Fatigue from Annual Assembly and Storage

Every time a prelit tree is taken down, packed away, and reassembled months later, it undergoes mechanical stress. Branches bend, wires twist, and connectors flex. Over several years, this repeated motion leads to material fatigue — particularly in lower-cost PVC and PE plastics used in most mass-market trees.

The lights themselves add weight and rigidity to the branches, reducing their natural flexibility. This increases the chance of cracking when folded, especially in colder garages or basements where plastic becomes more brittle. Once a wire inside a branch fractures, the affected section may flicker or go dark entirely. Because the damage occurs internally, it's rarely visible until it’s too late.

Storage methods also play a critical role. Many people store their trees in compressed bags without adequate protection. Dust, moisture, and pests like rodents can further degrade both the foliage and electrical components. A 2022 consumer report by The Home Appliance Review found that 68% of prelit tree failures occurred within three years, with improper storage cited as a leading contributing factor.

“Prelit trees are engineered for ease, not endurance. The moment you fold one up, you’re introducing micro-damage that accumulates silently.” — Marcus Lin, Senior Product Engineer at Evergreen Holiday Designs

Manufacturing Limitations and Cost-Cutting Practices

To keep prices competitive — often under $200 for full-size models — manufacturers cut corners in materials and quality control. LEDs may be low-grade, with inconsistent color temperatures or reduced lumen output over time. Wiring insulation might be thin, increasing the risk of short circuits or fire hazards, especially in older models.

One major issue is inconsistent soldering at connection points. In high-volume factories, automated processes may miss optimal heat application, resulting in cold solder joints that crack under thermal expansion. These weak links often fail after only a few heating-cooling cycles (from being turned on and off).

Another hidden flaw is poor strain relief at the base plug and hub connections. Without proper reinforcement, tugging on the power cord or misalignment during setup can damage internal contacts. Some brands use plastic housings that warp over time, making it harder to achieve secure connections year after year.

| Feature | Budget Models | Premium Models |

|---|---|---|

| Wiring Type | Series-circuit (single point of failure) | Parallel or segmented circuits |

| Bulb Quality | Generic LEDs, prone to dimming | High-efficiency, uniform LEDs |

| Wire Insulation | Thin PVC, degrades faster | Reinforced, heat-resistant coating |

| Connector Design | Basic plastic hubs | Metal-reinforced, weather-sealed |

| Avg. Lifespan (Consumer Reports) | 3–5 years | 7–10+ years |

Real Example: The Five-Year Fade-Out

Sarah Thompson of Portland, Oregon, purchased a 7.5-foot prelit tree in 2018 for $149. It arrived well-lit, with warm-white LEDs and easy-to-assemble sections. She stored it in a compression bag in her garage, following the included instructions. By the third holiday season, two upper sections began flickering. She contacted customer support, who sent replacement bulbs, but installation was difficult due to tight spacing.

In 2021, half the tree failed to light. Testing revealed broken wires near the trunk connector — a common failure point. No spare parts were available. By 2022, she replaced the tree with a non-prelit version and now uses detachable LED strands. “I saved time for three years,” she said, “but ended up spending more money and dealing with frustration. Next time, I’ll invest in quality or stick to separate lights.”

Sarah’s experience reflects a widespread pattern: initial satisfaction followed by gradual decline and eventual abandonment of the product. Her case illustrates how even careful handling cannot fully offset inherent design weaknesses.

How to Extend the Life of Your Prelit Tree

While no prelit tree lasts forever, certain practices can significantly delay failure and maximize value. These steps focus on minimizing physical stress, protecting electrical components, and catching issues early.

- Disassemble with care: Remove sections slowly, supporting lit branches to prevent bending beyond their tolerance.

- Inspect annually: Before setup, check for frayed wires, loose bulbs, or discoloration at connection points.

- Use a dedicated storage container: Opt for a rigid, vertical tree box instead of a compression bag. This prevents crushing and keeps dust out.

- Store in a climate-controlled space: Avoid attics, garages, or damp basements where temperature swings and humidity degrade materials.

- Limit runtime: Turn off the tree when not in use. Continuous operation generates heat that accelerates LED aging and wire insulation breakdown.

- Label sections: Mark each segment so they’re reassembled in the same orientation, reducing twisting forces on internal wiring.

Checklist: Buying a Long-Lasting Prelit Tree

- ✅ Choose parallel-wired or segmented lighting circuits

- ✅ Look for UL certification and built-in fuse protection

- ✅ Verify warranty length (5+ years indicates confidence)

- ✅ Check for metal pole construction (more stable than plastic)

- ✅ Prefer hinged branch designs (less folding = less stress)

- ✅ Read reviews specifically mentioning longevity (e.g., “still working after 6 years”)

- ✅ Consider buying from specialty retailers rather than big-box stores — they often carry higher-grade models

Frequently Asked Questions

Can I replace the lights on a prelit tree?

Generally, no. The lights are factory-integrated and not designed for user replacement. While individual bulbs in some models can be swapped using special tools, entire wire runs cannot be upgraded. Attempting DIY rewiring risks damaging the tree and voids any warranty.

Why does only part of my prelit tree light up?

This usually indicates a circuit break — either a burned-out bulb, loose connection, or damaged wire. Most prelit trees divide lights into multiple circuits per section. Test each bulb visually and ensure all connectors between sections are fully seated. Some manufacturers provide troubleshooting guides with voltage testers.

Are more expensive prelit trees worth it?

Yes, if longevity is a priority. Premium models often use better materials, superior wiring layouts, and improved structural design. They may cost 2–3 times more upfront but can last twice as long, offering better value over time. For seasonal users who want reliability, the investment pays off.

Conclusion: Rethinking Expectations and Habits

The shorter-than-expected lifespan of prelit Christmas trees isn’t solely due to poor quality — it’s the result of prioritizing convenience over resilience. Consumers expect these trees to perform like appliances, lasting a decade or more, but most are built more like seasonal electronics with limited duty cycles.

By understanding the engineering trade-offs, recognizing signs of wear early, and adopting protective storage and usage habits, owners can push their trees closer to their maximum potential. Still, the most effective strategy may be adjusting expectations: view a prelit tree not as a lifelong heirloom, but as a mid-term convenience tool with a realistic shelf life of 5 to 7 years under ideal conditions.

For those unwilling to compromise on durability, pairing a high-quality unlit tree with commercial-grade LED strings offers greater control, easier maintenance, and longer service. Ultimately, the choice depends on whether saving setup time outweighs the long-term cost of replacement.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?